Price: NS$4.4bn

Basic Information:

Displacement: 60,000 Tons.

Length: 330 Meters.

Layout: Deep-V Wave Piercing Low Resistance Monohull.

Range: Esssentially unlimited range. (Annual Maintenance Required.)

Top Speed: 100 Km/h.

Draught: 14.00 Meters.

Crew: 200 Sailors & Officers.

Construction: Ashigaru Steel 100-30-100mm Double Hull.

Powerplant: Taranis-6 Gen-IV MSR & Helium Turbines, 6x Kamewa SL Waterjets.

Electronics Suite: Testudo Mk. II, SANMEN, GXN-990, SFT-1221, NDA-1050, HMS-717.

Defensive Suite: AIDEN C1 - C4, Aspis Mk. II.

OVERVIEW:

The Anubis-Class Arsenal Ship is representative of an entirely new generation of thought on the role of warships. Anubis is both sleek and stealthy; her wave-piercing hull slices through rough seas and her long, slender shape powers through the water quietly under nuclear power. Anubis takes the place of several classes of warship simultaneously--she packs the punch of whole fleets of smaller destroyers while requiring only a fraction of the crew or maintenance. The type employs perhaps the most extensive defensive suite ever fielded on a warship and one of the most sophisticated sensor suites ever assembled with the very latest equipment. Anubis is equally at home as a carrier escort or standing alone, using her massive armament to project power deep into hostile territory. With the unique and diverse armament she offers, Anubis-class vessels can go toe-to-toe with some of the largest and most powerful warships ever built, or hunt deep-diving ultra-quiet submarines. Lessons learned by Myrmidon Tactical Design in the creation of other vessels, vehicles and aircraft have all come together to produce one of the very finest warships the world has ever seen.

ASHIGARU CONSTRUCTION:

Ashigaru vessels can be designed either as monohulls or catamarans, either will be strong, elegant and sleek, with a profile that displays a very low radar cross section and a quiet, hydrodynamically efficient shape. To this end, the entry point of Ashigaru ships will always be deep-V, wave-piercing hulls with a high degree of dead rise at the forefoot and a sleek, high dead rise amidships, allowing the hull to cut into waves with low vertical accelerations. A bulbous bow is placed at each forefoot, advancing the bow wave which allows the ship to slice through the water even in rough seas where the very fine point pierces waves instead of riding the tops; this design provides superior, stable ride quality in the highest sea states. The Ashigaru hull design underwent extensive computational modeling to minimize water resistance, drag and skin friction, with the wetted area coated in a sprayed-on resinous anechoic paint, which creates a slick, even, hydrodynamically efficient surface that glides through the water with minimum turbulence. As a design language, all Ashigaru ships exhibit a sleek, low shape above the water, all turrets and protrusions optimized to counter radar and provide a low return with all above-water surfaces coated in a non-magnetic radar absorbing paint.

The process of creating the Ashigaru hull begins in the Halau Kalama Steel Foundry, where raw iron is extracted from ore in a blast furnace. The virgin iron produced here is then blended with nickel, chromium, molybdenum, vanadium and titanium in an electric arc furnace to produce raw low carbon alloy steel. The molten steel is desiliconized, argon oxygen decarburized, desulphurized and degassed to produce a fine, dense steel. The steel is then austempered and aged to produce a fully stress-relieved nanocrystalline maraging steel, free of temperature gradients or impurities. The finished steel has superior resistance to chloride pitting, crevice corrosion, stress corrosion cracking and uniform corrosion; it is exceptionally tough and ductile. Under a microscope, it exhibits a very fine superaustentic structure with grain and matrix sizes smaller than 100 nanometers. These nano-scale microstructures produce oustanding physical and mechanical capabilities outside the known performance boundaries of existing steels. This nanocrystalline steel exhibits very high yield strength and tensile strength; the superaustentic maraging steel hull of the Anubis class is also completely nonmagnetic.

Completed steel plates leaving the Halau Kalama Foundry are finished in a multi-step protective process before shipment to Papeete Steelworks LTD where the vessels are assembled. The steel is processed first with an eco-friendly pickling process, then with the Smooth Clean Surface process, freeing the steel of mill scale and surface impurities. The bare steel is polished to a mirror finish and then zinc phosphated before leaving the foundry. Once at the steelworks, the finished steel is cold-rolled to the required shape for the vessel's hull and micro-aligned to its mate before being welded simultaneously on both sides of the hull in a two-pass method, first with a robotic laser arc tool, then by a friction stir process, ensuring that the final welded material is completely free of flaws or gaps. Final treatment of the welded areas by annealing is done to ensure that the blended joints keep their superaustentic nanocrystal structure and do not magnetize or undergo embrittlement.

Ashigaru vessels use a double hull, with 100mm thick identical inner and outer layers, spaced out with a 30mm gap supported by a gridwork of interlocking pylons. The interstitial space is filled with high-pressure ultralight foamed cement to create a nonresonant, redundant hull designed to defeat high explosive shaped charges. Inside the vessel, all bulkheads are made from the same steel as the hull, as are the core framework of the vessel, which is a trellis network of welded hollow steel tubes through which all the vessel's wiring looms will pass. The internal trellis structure is sealed in on both sides with braided kevlar fabric, creating all the rooms and hallways of the vessel's interior. Once sealed in, the steel trellis tubes are encased in the same high-pressure foamed cement used in the hull to deaden the vessel from vibration. This method of construction is incredibly rigid and resilient, able to absorb tremendous shocks throughout the hull without failing.

The interior of the vessel is treated with carbon aerogel insulation blanket, acoustic deadening foams, closed-cell gel membranes, viscoelastic padding, anti-microbial cotton filler and butyl rubber matting to silence the vessel. All interior surfaces wear a final coat of cool white acoustic dampening paint to finish the treatment. The uppermost level of the deckhouse is always made from a radar transparent composite, using reinforcing E-glass fabric in Cloisite 30B reinforced polyethermide nanocomposite matrix, chosen for its excellent electromagnetic transparency while remaining generally tough and structurally sound. Extensive modeling of the interior space ensured that the deckhouse would not constitute a "bright spot" on the ship in terms of its radar cross section while the housing itself was designed in such a way as to smooth the flow of air over it and contribute to the smooth, purposeful character of the vessel while hiding its antennae and the powerful radome from view. All structural aspects of the vessel underwent extensive computational stress modeling during the design process, with the vessel's final design optimized for efficiency, strength, low radar and acoustic signatures and the comfort of the crewmembers.

One of the primary design focuses of the Ashigaru design development was reducing the number of sailors placed in harm's way. To this end, many of the functions of the warship were automated, reducing the human workload and allowing a vessel with such incredible firepower, size and capability to run fully with a bare minimum of sailors and officers. Ashigaru ships are, for many sailors, almost eerie in their quietness and roomy interior. Ashigaru vessels are first and foremost warships. However, the well-being of the crew was a primary concern in its design. Because the ships are extensively automated and require few crew, accommodations are more luxurious than any other ocean-going naval vessels currently fielded. Each crewmember has his or her own cabin in a dormitory-style arrangement, with four cabins sharing a central washroom with complete hygiene facilities. All lighting throughout the vessel is by recessed, "ambient" cool-white LED's and all crew areas are equipped with speakers for communications or entertainment. In crew living areas, 110vac grounded, EMP shielded, power conditioned and fault protected outlets for recharging of personal devices while all water lines are temperature controlled throughout the ship. A central kitchen and dining hall serves the officers and crew aboard and carries only the very finest gourmet foods, enough to provide continously for the entire six month deployment. The vessel's cooks, while they are combat-qualified operators, are trained to executive chef standards.

The crew cabin's climate control system employs an extensive air scrubber system that precisely regulates air temperature with both heater and refrigeration units, forced air ultrasonic humidification and peltier heat pump dehumidification units, produces additional oxygen through a cold plasma ozone generator, pressure swing oxygen generator and membrane nitrogen separator, employs a negative ionic air purifier, controls odor with an activated charcoal system, utilizes a 0.03 micron CBRN filter and a final wet air scrubber system to produce cleanroom-grade atmosphere, a system considered the best in the world and the most advanced air scrubber array ever fielded. Integral to the vessel is a thermoionic process desalinization/membrane nanofiltration/reverse osmosis water disinfection/treatment system with 100,000 liters of drinkable filtered water stored in a compartment close to the vessel's reactor and powered by a heat exchanger from the reactor's coolant. The vessel's water management system intakes water from a special concealed opening near the vessel's bow and exhausts it near the vessel's propulsion system at the rear was and is capable of taking brackish or CBRN-contaminated seawater and wastewater beyond the potable standard, regulating PH balance, color, clarity and taste to produce absolutely pure distilled water for crew use.

The vessel's bridge uses large, high-contrast electrophoretic "E-Ink" color screens, displaying sixteen levels of greyscale and 4096 colors on LED backlights and optimized with an anti-glare coating, providing crisp, easily readable multifunction displays for all crew members, regardless of light conditions. Seats on the bridge and in all crew areas are heated and ventilated, mounted on shock-absorbing, vibration damped adjustable bases. Crew seats are specifically contoured with large side bolsters to keep lateral movement to a minimum during extreme maneuvers or rough seas and are made with dense memory foam padding finished in a soft baselayer fabric blend made from merino wool, X-Static silver fiber, cashmere and bamboo fiber. The vessel's bridge windows are made from Spinel transparent ceramic armor glass, which is treated for anti-reflective, anti-glare and polarization properties with a final external coating of gold/tin/indium to reduce radar reflections and a distortion-free hydrophobic nanocoating that keeps the glass free of optical obscurants. A transparent photovoltaic overlay on the inside of the glass precisely regulates tint through electrochromic technology and rejects harmful radiation. The glass is capable of stopping .50 caliber machine gun ammunition even fired at close range, and in most cases will survive 20mm cannon shots fired at distance.

The process of creating the Ashigaru hull begins in the Halau Kalama Steel Foundry, where raw iron is extracted from ore in a blast furnace. The virgin iron produced here is then blended with nickel, chromium, molybdenum, vanadium and titanium in an electric arc furnace to produce raw low carbon alloy steel. The molten steel is desiliconized, argon oxygen decarburized, desulphurized and degassed to produce a fine, dense steel. The steel is then austempered and aged to produce a fully stress-relieved nanocrystalline maraging steel, free of temperature gradients or impurities. The finished steel has superior resistance to chloride pitting, crevice corrosion, stress corrosion cracking and uniform corrosion; it is exceptionally tough and ductile. Under a microscope, it exhibits a very fine superaustentic structure with grain and matrix sizes smaller than 100 nanometers. These nano-scale microstructures produce oustanding physical and mechanical capabilities outside the known performance boundaries of existing steels. This nanocrystalline steel exhibits very high yield strength and tensile strength; the superaustentic maraging steel hull of the Anubis class is also completely nonmagnetic.

Completed steel plates leaving the Halau Kalama Foundry are finished in a multi-step protective process before shipment to Papeete Steelworks LTD where the vessels are assembled. The steel is processed first with an eco-friendly pickling process, then with the Smooth Clean Surface process, freeing the steel of mill scale and surface impurities. The bare steel is polished to a mirror finish and then zinc phosphated before leaving the foundry. Once at the steelworks, the finished steel is cold-rolled to the required shape for the vessel's hull and micro-aligned to its mate before being welded simultaneously on both sides of the hull in a two-pass method, first with a robotic laser arc tool, then by a friction stir process, ensuring that the final welded material is completely free of flaws or gaps. Final treatment of the welded areas by annealing is done to ensure that the blended joints keep their superaustentic nanocrystal structure and do not magnetize or undergo embrittlement.

Ashigaru vessels use a double hull, with 100mm thick identical inner and outer layers, spaced out with a 30mm gap supported by a gridwork of interlocking pylons. The interstitial space is filled with high-pressure ultralight foamed cement to create a nonresonant, redundant hull designed to defeat high explosive shaped charges. Inside the vessel, all bulkheads are made from the same steel as the hull, as are the core framework of the vessel, which is a trellis network of welded hollow steel tubes through which all the vessel's wiring looms will pass. The internal trellis structure is sealed in on both sides with braided kevlar fabric, creating all the rooms and hallways of the vessel's interior. Once sealed in, the steel trellis tubes are encased in the same high-pressure foamed cement used in the hull to deaden the vessel from vibration. This method of construction is incredibly rigid and resilient, able to absorb tremendous shocks throughout the hull without failing.

The interior of the vessel is treated with carbon aerogel insulation blanket, acoustic deadening foams, closed-cell gel membranes, viscoelastic padding, anti-microbial cotton filler and butyl rubber matting to silence the vessel. All interior surfaces wear a final coat of cool white acoustic dampening paint to finish the treatment. The uppermost level of the deckhouse is always made from a radar transparent composite, using reinforcing E-glass fabric in Cloisite 30B reinforced polyethermide nanocomposite matrix, chosen for its excellent electromagnetic transparency while remaining generally tough and structurally sound. Extensive modeling of the interior space ensured that the deckhouse would not constitute a "bright spot" on the ship in terms of its radar cross section while the housing itself was designed in such a way as to smooth the flow of air over it and contribute to the smooth, purposeful character of the vessel while hiding its antennae and the powerful radome from view. All structural aspects of the vessel underwent extensive computational stress modeling during the design process, with the vessel's final design optimized for efficiency, strength, low radar and acoustic signatures and the comfort of the crewmembers.

One of the primary design focuses of the Ashigaru design development was reducing the number of sailors placed in harm's way. To this end, many of the functions of the warship were automated, reducing the human workload and allowing a vessel with such incredible firepower, size and capability to run fully with a bare minimum of sailors and officers. Ashigaru ships are, for many sailors, almost eerie in their quietness and roomy interior. Ashigaru vessels are first and foremost warships. However, the well-being of the crew was a primary concern in its design. Because the ships are extensively automated and require few crew, accommodations are more luxurious than any other ocean-going naval vessels currently fielded. Each crewmember has his or her own cabin in a dormitory-style arrangement, with four cabins sharing a central washroom with complete hygiene facilities. All lighting throughout the vessel is by recessed, "ambient" cool-white LED's and all crew areas are equipped with speakers for communications or entertainment. In crew living areas, 110vac grounded, EMP shielded, power conditioned and fault protected outlets for recharging of personal devices while all water lines are temperature controlled throughout the ship. A central kitchen and dining hall serves the officers and crew aboard and carries only the very finest gourmet foods, enough to provide continously for the entire six month deployment. The vessel's cooks, while they are combat-qualified operators, are trained to executive chef standards.

The crew cabin's climate control system employs an extensive air scrubber system that precisely regulates air temperature with both heater and refrigeration units, forced air ultrasonic humidification and peltier heat pump dehumidification units, produces additional oxygen through a cold plasma ozone generator, pressure swing oxygen generator and membrane nitrogen separator, employs a negative ionic air purifier, controls odor with an activated charcoal system, utilizes a 0.03 micron CBRN filter and a final wet air scrubber system to produce cleanroom-grade atmosphere, a system considered the best in the world and the most advanced air scrubber array ever fielded. Integral to the vessel is a thermoionic process desalinization/membrane nanofiltration/reverse osmosis water disinfection/treatment system with 100,000 liters of drinkable filtered water stored in a compartment close to the vessel's reactor and powered by a heat exchanger from the reactor's coolant. The vessel's water management system intakes water from a special concealed opening near the vessel's bow and exhausts it near the vessel's propulsion system at the rear was and is capable of taking brackish or CBRN-contaminated seawater and wastewater beyond the potable standard, regulating PH balance, color, clarity and taste to produce absolutely pure distilled water for crew use.

The vessel's bridge uses large, high-contrast electrophoretic "E-Ink" color screens, displaying sixteen levels of greyscale and 4096 colors on LED backlights and optimized with an anti-glare coating, providing crisp, easily readable multifunction displays for all crew members, regardless of light conditions. Seats on the bridge and in all crew areas are heated and ventilated, mounted on shock-absorbing, vibration damped adjustable bases. Crew seats are specifically contoured with large side bolsters to keep lateral movement to a minimum during extreme maneuvers or rough seas and are made with dense memory foam padding finished in a soft baselayer fabric blend made from merino wool, X-Static silver fiber, cashmere and bamboo fiber. The vessel's bridge windows are made from Spinel transparent ceramic armor glass, which is treated for anti-reflective, anti-glare and polarization properties with a final external coating of gold/tin/indium to reduce radar reflections and a distortion-free hydrophobic nanocoating that keeps the glass free of optical obscurants. A transparent photovoltaic overlay on the inside of the glass precisely regulates tint through electrochromic technology and rejects harmful radiation. The glass is capable of stopping .50 caliber machine gun ammunition even fired at close range, and in most cases will survive 20mm cannon shots fired at distance.

POWERPLANT & PROPULSION:

To power its fleet of surface vessels, Myrmidon Tactical Design created the Taranis powerplant system. So-named for a Celtic and Gaulic god of thunder often associated with a wheel and the power of the MTD arrangement coupled to its wheel-like reactor design, the Taranis powerplant system is comprised of a number of separate systems which are safe, compact, quiet, powerful and redundant. The primary cooling loop of a Taranis reactor circulates by convection only and this molten salt coolant also provides the ship's batteries with electrolyte. The secondary cooling loop is modular, passing a number of high pressure secondary cooling loops through the primary coolant with heat exchangers. This helps to moderate the temperature of the primary coolant and it also heats the secondary cooling medium, pure helium gas, to extreme temperature. As the helium gas expands, it accelerates and powers specifically-designed low loss gas turbines. The turbines spin electric generators and the electrical generation system powers electric motors used for propulsion. The number of gas turbines gives each Taranis powerplant its name, so one with four turbines will be Taranis-4, while one with six turbines will be Taranis-6.

Reactor:

All Myrmidon-designed surface vessels takes their power from a single fourth generation molten salt reactor. Using FLIBe (Fluorine Lithium Beryllium) salts for cooling moderates the risk of corrosion and is an inherently-safe and extremely efficient coolant. The primary advantage of the MSR is a low overall reactor size while being passively safe and having a very high specific power output. The prismatic core of the MSR uses QUADRISO fuel rods to moderate excess reactivity and use Thorium as the primary fuel. The MSR's core consists of a graphite cylinder with a radius of 4m and a height of 10m which includes 1m axial reflectors at the top and bottom. The core has three concentric fuel rings, each consisting of 36 hexagonal blocks with an insterstitial gap of 0.2 cm. Each block contains 108 coolant channels and 216 fuel pins. Operating at around 1,000 C, this compact design required the use of a special molybdenum-strengthened inconel superalloy for the construction of the reactor. This alloy resists thermal expansion and is highly resilient to stress and corrosion. Each component of the reactor core was milled on a five-axis machine from a forged block of the alloy, with the shavings collected and reforged to bring waste to nearly zero. The exceptional precision of this method, while more expensive and more time-consuming than typical production methods creates precicely-fitted tolerances below 0.0001 cm across the entire reactor assembly. The reactor's coolant circulates by natural convection; this method is noiseless, compact and efficient, requiring no noisy pumps and eliminating hundreds of points of failure endemic of pressurized water reactors.

Turbine Loop:

The molten salt coolant primary coolant loop drives independent secondary cooling loops that pass high-pressure refrigerated helium through graphite heat exchangers. The number of helium loops is dependent on the required power of the vessel and can be easily scaled to meet the needs of small and large vessels. After exiting the heat exchanger, the helium is blown into a helium scrubber at 110 bar. Once the helium exits the charcoal scrubber it is cleanroom-grade and free of any entrained particles. Each closed loop of superheated helium then enters the low pressure inlet of its own gas turbine engine. These specifically-designed turbines utilize ultralight carbon/carbon composite fanblades and cryogenically-machined titanium compressor blisks throughout to minimize weight and maximize power efficiency and response. The powerplants are bleedless designs, with power take-off from the intermediate-pressure (IP) spool instead of the high-pressure (HP) spool found in other turbines. The six robust gas turbines operate under full FADEC control managed by the onboard computer, each spinning a helium cooled neodymium magnet synchronous turbogenerator rated to 100 megawatts of electrical power. These gas turbines operate completely closed-cycle, with a regenerative cooling system that feeds the inlet of an absorption refrigerator, providing constant cold and hot water for use across the ship via heat exchangers. Helium exiting the cooling section is recycled to the inlet of the reactor's heat exchanger at a refrigerated temperature. The vessel's powerplant is located amidships below the bridge along with its electric drivetrain and energy reserve comprised of high-temperature ZEBRA molten salt batteries using circulated reactor coolant as the electrolyte. The ZEBRA batteries are fed by the vessel's 100-megawatt electric motors; this ultra-quiet and very high-power arrangement in turn feeds power to a common-bus solid state power grid that distributes energy to the entire vessel, including its Rolls-Royce Kamera SL waterjets.

Propulsion:

These waterjet use specifically modeled, low-noise hull inlets to draw water into the propulsors, which provide for extremely high efficiency (up to 90%) and remarkably quiet, massive thrust; each rated at 67,000 shaft horsepower. These propulsive units are fully modular, integrated into the design of every Myrmidon surface vessel and can maintain high speeds through extremely rough or choppy seas, up to Sea State 7. Each propulsor is completely submerged; with three-dimensional thrust vectoring nozzles and reversing shrouds, the arrangement is very agile and maneuverable while maintaining the sonic profile of much smaller vessels. The waterjets are specially designed with high-speed propulsion assemblies; each uses a series of five counterrotating magnetically powered rim driven propeller assemblies with nine skewback propellers per hub. Placing the propeller tips in the center dramatically reduces cavitation and vibration, presenting the absolute minimum in noise or turbulence.

Since each propeller is driven separately, there is no transmission noise or vibration, with electrical power transmitted directly into propulsion. This coaxial/contrarotating layout has the advantage of straightening the flow of water through the pumpjet, further reducing turbulence and cavitation. A variable-geometry pumpjet compression nozzle, covered in non-resonant anechoic coatings optimizes speed and ultimate thrust by computer control, vastly increasing the ability of the Taranis-equipped vessel to accelerate and maneuver. The combination of all-electric drive, pumpjets and contrarotating rim-driven propulsors make a Taranis-equipped ship one of the fastest vessels in the water and many times more silent by orders of magnitude than traditional direct-drive, pressurized water reactor/steam turbine powerplants.

Reactor:

All Myrmidon-designed surface vessels takes their power from a single fourth generation molten salt reactor. Using FLIBe (Fluorine Lithium Beryllium) salts for cooling moderates the risk of corrosion and is an inherently-safe and extremely efficient coolant. The primary advantage of the MSR is a low overall reactor size while being passively safe and having a very high specific power output. The prismatic core of the MSR uses QUADRISO fuel rods to moderate excess reactivity and use Thorium as the primary fuel. The MSR's core consists of a graphite cylinder with a radius of 4m and a height of 10m which includes 1m axial reflectors at the top and bottom. The core has three concentric fuel rings, each consisting of 36 hexagonal blocks with an insterstitial gap of 0.2 cm. Each block contains 108 coolant channels and 216 fuel pins. Operating at around 1,000 C, this compact design required the use of a special molybdenum-strengthened inconel superalloy for the construction of the reactor. This alloy resists thermal expansion and is highly resilient to stress and corrosion. Each component of the reactor core was milled on a five-axis machine from a forged block of the alloy, with the shavings collected and reforged to bring waste to nearly zero. The exceptional precision of this method, while more expensive and more time-consuming than typical production methods creates precicely-fitted tolerances below 0.0001 cm across the entire reactor assembly. The reactor's coolant circulates by natural convection; this method is noiseless, compact and efficient, requiring no noisy pumps and eliminating hundreds of points of failure endemic of pressurized water reactors.

Turbine Loop:

The molten salt coolant primary coolant loop drives independent secondary cooling loops that pass high-pressure refrigerated helium through graphite heat exchangers. The number of helium loops is dependent on the required power of the vessel and can be easily scaled to meet the needs of small and large vessels. After exiting the heat exchanger, the helium is blown into a helium scrubber at 110 bar. Once the helium exits the charcoal scrubber it is cleanroom-grade and free of any entrained particles. Each closed loop of superheated helium then enters the low pressure inlet of its own gas turbine engine. These specifically-designed turbines utilize ultralight carbon/carbon composite fanblades and cryogenically-machined titanium compressor blisks throughout to minimize weight and maximize power efficiency and response. The powerplants are bleedless designs, with power take-off from the intermediate-pressure (IP) spool instead of the high-pressure (HP) spool found in other turbines. The six robust gas turbines operate under full FADEC control managed by the onboard computer, each spinning a helium cooled neodymium magnet synchronous turbogenerator rated to 100 megawatts of electrical power. These gas turbines operate completely closed-cycle, with a regenerative cooling system that feeds the inlet of an absorption refrigerator, providing constant cold and hot water for use across the ship via heat exchangers. Helium exiting the cooling section is recycled to the inlet of the reactor's heat exchanger at a refrigerated temperature. The vessel's powerplant is located amidships below the bridge along with its electric drivetrain and energy reserve comprised of high-temperature ZEBRA molten salt batteries using circulated reactor coolant as the electrolyte. The ZEBRA batteries are fed by the vessel's 100-megawatt electric motors; this ultra-quiet and very high-power arrangement in turn feeds power to a common-bus solid state power grid that distributes energy to the entire vessel, including its Rolls-Royce Kamera SL waterjets.

Propulsion:

These waterjet use specifically modeled, low-noise hull inlets to draw water into the propulsors, which provide for extremely high efficiency (up to 90%) and remarkably quiet, massive thrust; each rated at 67,000 shaft horsepower. These propulsive units are fully modular, integrated into the design of every Myrmidon surface vessel and can maintain high speeds through extremely rough or choppy seas, up to Sea State 7. Each propulsor is completely submerged; with three-dimensional thrust vectoring nozzles and reversing shrouds, the arrangement is very agile and maneuverable while maintaining the sonic profile of much smaller vessels. The waterjets are specially designed with high-speed propulsion assemblies; each uses a series of five counterrotating magnetically powered rim driven propeller assemblies with nine skewback propellers per hub. Placing the propeller tips in the center dramatically reduces cavitation and vibration, presenting the absolute minimum in noise or turbulence.

Since each propeller is driven separately, there is no transmission noise or vibration, with electrical power transmitted directly into propulsion. This coaxial/contrarotating layout has the advantage of straightening the flow of water through the pumpjet, further reducing turbulence and cavitation. A variable-geometry pumpjet compression nozzle, covered in non-resonant anechoic coatings optimizes speed and ultimate thrust by computer control, vastly increasing the ability of the Taranis-equipped vessel to accelerate and maneuver. The combination of all-electric drive, pumpjets and contrarotating rim-driven propulsors make a Taranis-equipped ship one of the fastest vessels in the water and many times more silent by orders of magnitude than traditional direct-drive, pressurized water reactor/steam turbine powerplants.

TESTUDO MK. II:

The Testudo Mk. II system is a passive/active vessel defense mechanism with integrated sensors and fire control for offensive and defensive weapons. This "system of systems" incorporates a variety of sensors to provide precise, millisecond-accurate information to the vessel while remaining a compact and unobtrusive system. Several layers of passive and active defense extend out tens of kilometers from the vessel itself and can provide an umbrella of protection to ground, sea or air assets operating nearby. Testudo protects the vessel from all types of guided and unguided threats including laser, radar, infrared or optically-guided missiles, direct and indirect fire artillery, rockets, grenades and mortars. Integrated counter-battery, direct and indirect fire control suites broadcast firing solutions to all allied assets in the area in addition to automatic weapon selection and firing solutions for its own weapons. For the vessel's own weapons suite, Testudo dramatically increases the effectiveness of all types of onboard weapons including direct fire cannons and guns; for defensive weapons, the system provides a very high rate of interception, increasing the vessel's survivability by orders of magnitude over a ship not equipped with it. The Testudo Mk. II system is fully networked as one unified system with all sensors, offensive and defensive weapons and the SANMEN communications suite. The onboard computer integrates this information, allowing the crew to make the most informed decisions possible, staying constantly connected to the command structure.

Ships equipped with Testudo house an extremely powerful central computer system which handles not only all the functions required by the ship, its sensors and weapons systems, but the duties of fusing information streamed from all other allied sources into a unified picture of the battlespace. The computer chosen for this purpose was a scalar-cabinet air cooled supercomputer, built as a collaboration between Cray Supercomputer and Advanced Micro Devices, or AMD. The computer is housed near the ship's reactor inside the absorption refrigerator where it can take advantage of the chilled atmosphere to cool itself. The computer is housed in six sequential cabinets, and is modeled on the Cray XK7 Supercomputer. In total, the computer uses 576 Opteron 6386 processors with 9,216 cores, supported by 72 terabytes of Radeon ECC DDR3 1333 SDRAM. The processors and memory are aided by 576 FirePro S10000 GPU's with 3.375 terabytes of GDDR5 memory and the entire system contains 576 LSI Nytro WarpDrive BFH8-3200 Flash Accelerators with 1,800 terabytes of solid state MLC hard drive space. Data is carried throughout the ship on armored, 500-strand glass fiber optic cable.

The computer system manages all functions of the ship, its powerplant, communications network, sensor suite and weapons, resolves raw data and processes it into usable information, integrating that data with information from all sources to create a single, unified picture of the entire battlespace and all of the personnel and resources within it. This system provides the Anubis class with 600+ teraflops of computing power and sub-microsecond latency for an incredibly versatile central computer capable of handling the most demanding loads and intense calculations. The ship's onboard computer provides stunningly clear, accurate and fast sensor fusion from multiple sources, blended cohesively and rendered flawlessly, broadcasting that networked, unified picture back across the communications network to allied resources, ensuring that all friendly troops have the most complete intelligence and latest information possible.

Testudo Mk. II includes an onboard inertial guidance suite for navigation, which only periodically references GPS as a redundant calibration check, but is considered extremely accurate without any access to GPS whatsoever. The guidance package makes use of numerous breakthroughs in micro-scale construction and computing. The Timing and Inertial Measurement Unit is an array of dozens of tiny blown, ground and polished quartz mushroom and wineglass gyroscopic sensors, coupled to a powerful master clock and linked to accelerometers and magnetometers, measuring six axes of rotation, synchronized in real time and sensor-fused to provide highly accurate tracking of time, altitude, distance and course. A path can be laid out pre-mission or during a mission, which is translated onto GPS-synchronized maps with turn by turn corrections displayed on a map overlay for the crew, with terrain features and intelligence information from the SANMEN communications network. A ring-laser gyroscope provides a secondary, redundant but highly accurate reference which is used for constant check and recalibration of the Micro-PNT/TIMU system. The extremely accurate information generated by the Tetsudo Mk. II guidance system is capable of delivering the vessel on target with pinpoint accuracy, in most cases inside three meters of the predesignated point, all without any reference to global positioning satellites whatsoever and only using onboard communications receivers for mid-course correction.

Ships equipped with Testudo house an extremely powerful central computer system which handles not only all the functions required by the ship, its sensors and weapons systems, but the duties of fusing information streamed from all other allied sources into a unified picture of the battlespace. The computer chosen for this purpose was a scalar-cabinet air cooled supercomputer, built as a collaboration between Cray Supercomputer and Advanced Micro Devices, or AMD. The computer is housed near the ship's reactor inside the absorption refrigerator where it can take advantage of the chilled atmosphere to cool itself. The computer is housed in six sequential cabinets, and is modeled on the Cray XK7 Supercomputer. In total, the computer uses 576 Opteron 6386 processors with 9,216 cores, supported by 72 terabytes of Radeon ECC DDR3 1333 SDRAM. The processors and memory are aided by 576 FirePro S10000 GPU's with 3.375 terabytes of GDDR5 memory and the entire system contains 576 LSI Nytro WarpDrive BFH8-3200 Flash Accelerators with 1,800 terabytes of solid state MLC hard drive space. Data is carried throughout the ship on armored, 500-strand glass fiber optic cable.

The computer system manages all functions of the ship, its powerplant, communications network, sensor suite and weapons, resolves raw data and processes it into usable information, integrating that data with information from all sources to create a single, unified picture of the entire battlespace and all of the personnel and resources within it. This system provides the Anubis class with 600+ teraflops of computing power and sub-microsecond latency for an incredibly versatile central computer capable of handling the most demanding loads and intense calculations. The ship's onboard computer provides stunningly clear, accurate and fast sensor fusion from multiple sources, blended cohesively and rendered flawlessly, broadcasting that networked, unified picture back across the communications network to allied resources, ensuring that all friendly troops have the most complete intelligence and latest information possible.

Testudo Mk. II includes an onboard inertial guidance suite for navigation, which only periodically references GPS as a redundant calibration check, but is considered extremely accurate without any access to GPS whatsoever. The guidance package makes use of numerous breakthroughs in micro-scale construction and computing. The Timing and Inertial Measurement Unit is an array of dozens of tiny blown, ground and polished quartz mushroom and wineglass gyroscopic sensors, coupled to a powerful master clock and linked to accelerometers and magnetometers, measuring six axes of rotation, synchronized in real time and sensor-fused to provide highly accurate tracking of time, altitude, distance and course. A path can be laid out pre-mission or during a mission, which is translated onto GPS-synchronized maps with turn by turn corrections displayed on a map overlay for the crew, with terrain features and intelligence information from the SANMEN communications network. A ring-laser gyroscope provides a secondary, redundant but highly accurate reference which is used for constant check and recalibration of the Micro-PNT/TIMU system. The extremely accurate information generated by the Tetsudo Mk. II guidance system is capable of delivering the vessel on target with pinpoint accuracy, in most cases inside three meters of the predesignated point, all without any reference to global positioning satellites whatsoever and only using onboard communications receivers for mid-course correction.

COMMUNICATIONS SUITE:

Testudo Mk. II equipped warships are fully networked to other allied forces using a communications system called SANMEN, or Secured Architecture Network, Multiple Exchange Nodes. SANMEN is a network operating on a hierarchical node architecture, meaning that groups share information with each other and pass information up to the next group, which has access to all the data of the groups below it. Each group (in the case of a military operation, each unit) represents a node and that unit's command center is the "hive" of that node, with access to all others in it. SANMEN employs an extremely broadband approach, automatically sensing "white spaces" from ultra-low frequency to ultra-high frequency, taking advantage of unoccupied frequencies and transmitting on all unoccupied frequencies, electronically scanning and switching between them according to an algorithm which minimizes the possibility of detection. Because this network transmits on sometimes hundreds of frequencies simultaneously, it maintains an extremely high bandwidth, which can be as much as ten gigabytes per second in upload and download when transmitting line-of-sight. All allied vehicles carry SANMEN repeaters, which maximizes throughput and creates smaller Ad-Hoc networks within each node.

SANMEN operates on a 512-bit symmetrical key encryption and is fully digital, transmitting voice, text and data at extremely high speeds with very high security. Because the network transmits on such a broad range of frequencies, the network automatically optimizes the transmission according to the identifiers of the subscribers in contact, including submarines, surface ships, vehicles, airships, aircraft, drones and individual operators. For example, a submerged submarine will need to transmit on ultra-low frequencies, so SANMEN will automatically adjust the transmission at the nearest relay point to transmit only those frequencies. Each subscriber on the network carries a unique network identification that is provisioned according to individual settings; your network privilege depends on rank and role, vehicle type and hierarchical position. SANMEN will automatically present text in the language preferred by the subscriber and will present user status on the allied positional maps according to individual factors such as vehicle diagnostics, ammunition status, time-to-target and personal vitals. Each registered user down to individual operators is geolocated by a GPS transponder in their SANMEN equipment and that information is used to track the movement of allied forces. SANMEN provides turn-by-turn updated directions according to realtime target and objective data. SANMEN is cross-compatible to all existing allied networks and is reverse-compatible to all older communication systems such as MADL and MAGSNET, though access to SANMEN information will be limited according to the network provisions of the user.

SANMEN is transmitted primarily from Warden-Class Airships and Anubis-Class Arsenal Ships where the "central hive" of the SANMEN system is integrated with those vessel's onboard supercomputers. Both vessel types carry solid state, EMP-hardened transmitters rated to 500 kilowatts effective radiated power. These signals are transmitted through an extreme-wideband liquid plasma antenna located in the uppermost level of the deck house on the Anubis class, facilitating the 2,000 switch-per-second electronically scanned nature of the network. Individual users transmit back on fixed frequencies but receive communication through actively-scanned, encrypted broadband receivers. The command center aboard both Warden class airships and Anubis class Arsenal ships have access to the "full picture" of the battlespace and use its combined fusion of information collected from its onboard sensors and information received from SANMEN to fuse together a complete picture of the battlespace and relay that information back down through the network to individual nodes and subscribers. Each of the cental hives have a generally accepted transmission range from cruising altitude of roughly 300 kilometers, though this is limitlessly multiplied by other allied presences repeating the network information on. In the case of there being too great a distance or other mitigating factors prohibiting direct transmission, SANMEN information can be backhauled over satellite uplink.

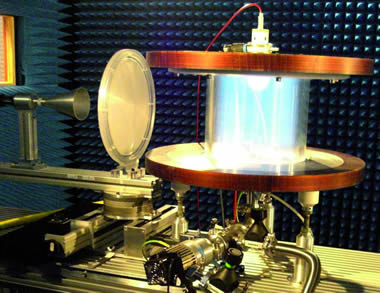

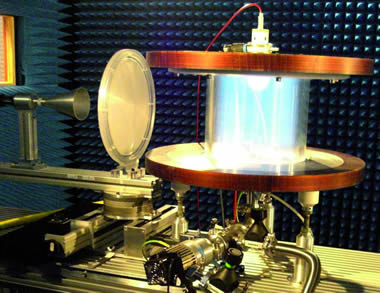

The plasma antenna contains no moving parts and is an extremely robust design containing helium gas at very low pressure and two heimholtz coils which structure the plasma and impart a cylindrical geometry, which is effectively the plasma lens. The density of electrons is at a maximum in the axis of the cylinder and cancels out at the wall of the chamber. An electromagnetic wave, produced by a funnel antenna and focused by a metamaterial lens, meets this plasma of radially variable electronic density and undergoes a deviation from its propagation axis. The angle of this deviation may be modified by controlling the density of electrons by, for example, changing the pressure of the gases in the chamber, or by modulating the discharge current.

The funnel antenna transmits the signal to be broadcast into a three-dimensional, lightweight metamaterial lens that focuses radio waves with extreme precision. The concave lens exhibits a property called negative refraction, bending electromagnetic waves in exactly the opposite sense from which a normal concave lens would work. Concave lenses typically radiate radio waves like spokes from a wheel. In this metamaterial lens, however, radio waves converge, focusing on a single, precise point — a property impossible to replicate in natural materials. The metamaterial’s extraordinary properties are determined largely by its structure. A material can refract waves differently depending on the shape of individual units within a material, and the arrangement of those units as a whole. For this lens, a blocky, S-shaped “unit cell” whose shape refracts radio waves in particular directions was used. The unit shape was used as the basis for the concave lens, creating the rough shape from more than 4,000 unit cells, each only a few millimeters wide. To fabricate the design, 3-D printing was utilized, building a lens layer by layer from a polymer solution, washing away any residue with a high-pressure water jet and coating each layer with a fine mist of copper to give the lens a conductive surface. This design produces a tight, highly focused beam of radio energy which is fired into the plasma chamber, where both the direction of the radio energy and its frequency are modulated from extremely low to extremely high frequencies. This antenna design has very low power loss and is a revolutionary method of communicating with different platforms on different frequencies across different network types at distance and with a compact antenna that draws very low power and generates extremely efficient broadband signals.

SANMEN operates on a 512-bit symmetrical key encryption and is fully digital, transmitting voice, text and data at extremely high speeds with very high security. Because the network transmits on such a broad range of frequencies, the network automatically optimizes the transmission according to the identifiers of the subscribers in contact, including submarines, surface ships, vehicles, airships, aircraft, drones and individual operators. For example, a submerged submarine will need to transmit on ultra-low frequencies, so SANMEN will automatically adjust the transmission at the nearest relay point to transmit only those frequencies. Each subscriber on the network carries a unique network identification that is provisioned according to individual settings; your network privilege depends on rank and role, vehicle type and hierarchical position. SANMEN will automatically present text in the language preferred by the subscriber and will present user status on the allied positional maps according to individual factors such as vehicle diagnostics, ammunition status, time-to-target and personal vitals. Each registered user down to individual operators is geolocated by a GPS transponder in their SANMEN equipment and that information is used to track the movement of allied forces. SANMEN provides turn-by-turn updated directions according to realtime target and objective data. SANMEN is cross-compatible to all existing allied networks and is reverse-compatible to all older communication systems such as MADL and MAGSNET, though access to SANMEN information will be limited according to the network provisions of the user.

SANMEN is transmitted primarily from Warden-Class Airships and Anubis-Class Arsenal Ships where the "central hive" of the SANMEN system is integrated with those vessel's onboard supercomputers. Both vessel types carry solid state, EMP-hardened transmitters rated to 500 kilowatts effective radiated power. These signals are transmitted through an extreme-wideband liquid plasma antenna located in the uppermost level of the deck house on the Anubis class, facilitating the 2,000 switch-per-second electronically scanned nature of the network. Individual users transmit back on fixed frequencies but receive communication through actively-scanned, encrypted broadband receivers. The command center aboard both Warden class airships and Anubis class Arsenal ships have access to the "full picture" of the battlespace and use its combined fusion of information collected from its onboard sensors and information received from SANMEN to fuse together a complete picture of the battlespace and relay that information back down through the network to individual nodes and subscribers. Each of the cental hives have a generally accepted transmission range from cruising altitude of roughly 300 kilometers, though this is limitlessly multiplied by other allied presences repeating the network information on. In the case of there being too great a distance or other mitigating factors prohibiting direct transmission, SANMEN information can be backhauled over satellite uplink.

The plasma antenna contains no moving parts and is an extremely robust design containing helium gas at very low pressure and two heimholtz coils which structure the plasma and impart a cylindrical geometry, which is effectively the plasma lens. The density of electrons is at a maximum in the axis of the cylinder and cancels out at the wall of the chamber. An electromagnetic wave, produced by a funnel antenna and focused by a metamaterial lens, meets this plasma of radially variable electronic density and undergoes a deviation from its propagation axis. The angle of this deviation may be modified by controlling the density of electrons by, for example, changing the pressure of the gases in the chamber, or by modulating the discharge current.

The funnel antenna transmits the signal to be broadcast into a three-dimensional, lightweight metamaterial lens that focuses radio waves with extreme precision. The concave lens exhibits a property called negative refraction, bending electromagnetic waves in exactly the opposite sense from which a normal concave lens would work. Concave lenses typically radiate radio waves like spokes from a wheel. In this metamaterial lens, however, radio waves converge, focusing on a single, precise point — a property impossible to replicate in natural materials. The metamaterial’s extraordinary properties are determined largely by its structure. A material can refract waves differently depending on the shape of individual units within a material, and the arrangement of those units as a whole. For this lens, a blocky, S-shaped “unit cell” whose shape refracts radio waves in particular directions was used. The unit shape was used as the basis for the concave lens, creating the rough shape from more than 4,000 unit cells, each only a few millimeters wide. To fabricate the design, 3-D printing was utilized, building a lens layer by layer from a polymer solution, washing away any residue with a high-pressure water jet and coating each layer with a fine mist of copper to give the lens a conductive surface. This design produces a tight, highly focused beam of radio energy which is fired into the plasma chamber, where both the direction of the radio energy and its frequency are modulated from extremely low to extremely high frequencies. This antenna design has very low power loss and is a revolutionary method of communicating with different platforms on different frequencies across different network types at distance and with a compact antenna that draws very low power and generates extremely efficient broadband signals.

SENSOR SUITE:

The Testudo suite puts a premium on situational awareness in all possible aspects. To this effect, the vessel's onboard sensor suite distributes its various apertures throughout the ship, giving the vessel an optimal, birds-eye-view of the area around it, along with integrating its bow-mounted sonar. There are several systems working coherently aboard the Testudo suite, which are outlined below.

GXN-990, Battlespace Reconnaissance Radar:

GXN-990 is a solid state AESA (Active Electronically Scanned Array) radar operating simultaneously and coherently in the EHF and L-Band modes. The GXN is comprised of four 36-element arrays, or synthetic apertures mounted on the deckhouse of the vessel to which it is fitted, facing 90 degrees apart. The beams vertical elevation, horizontal training and compensation for ship movement is accomplished electronically while shifting frequencies randomly more than 2,000 times per second. Each array transmits 20 kilowatts through its 7,200 carbon nanotube apertures and each is cooled by 75,000 BTU coldplates. The methodology used by the 990 is called Video Synthetic Aperture Radar / Surface Moving Target Indicator, or ViSAR/SMTI, which denies the enemy to protect themselves by operating in cloudy weather, or while other atmospheric conditions such as dust, smoke or haze would otherwise hinder optical detection. The GXN-990 is a 3D radar system, effective against stealthy aircraft and missiles, providing capability to track and analyze three-dimensional objects against clutter, in poor conditions and in the littoral environment. The system's large sensitivity allows for the early detection and tracking of very small and/or stealthy aircraft and missiles, very small boats, mines, vehicles or even troop movements.

The accurate 3D target information provides an essential contribution to the threat evaluation process, especially in multiple attack scenarios and it allows the fire control system to lock-on rapidly. The maximum range of the system is 500 kilometers and more than 70 degrees of elevation, at which the system can track more than 1,000 targets simultaneously. The GXN-990 is said to be able to detect even the stealthiest missiles at 100 km and is able to detect and track outer atmosphere objects at short range, making it an essential part of a Theatre Ballistic Missile Defence system. The GXN provides a “God’s eye view” of moving objects throughout the area of operations, despite the dark of night, the smoke of oil fires, or the dust of sandstorms. The ability to precisely and accurately strike enemy forces from the sea—sometimes when in close contact with friendly forces in near-zero visibility while accurately highlighting movement on the surface against clutter and in extremely poor visibility conditions means that the Anubis's fire control system or allied forces will have maximum accuracy for the use of weapons systems, even in complex and chaotic situations, in the poorest of conditions. GXN-990 provides a continuous observation capability, maximizing detection resolution, even to the point of being able to accurately pinpoint enemy troop movements on foot on land or the movement of small, hand-launched drones.

The accurate 3D target information provides an essential contribution to the threat evaluation process, especially in multiple attack scenarios and it allows the fire control system to lock-on rapidly. The maximum range of the system is 500 kilometers and more than 70 degrees of elevation, at which the system can track more than 1,000 targets simultaneously. The GXN-990 is said to be able to detect even the stealthiest missiles at 100 km and is able to detect and track outer atmosphere objects at short range, making it an essential part of a Theatre Ballistic Missile Defence system. The GXN provides a “God’s eye view” of moving objects throughout the area of operations, despite the dark of night, the smoke of oil fires, or the dust of sandstorms. The ability to precisely and accurately strike enemy forces from the sea—sometimes when in close contact with friendly forces in near-zero visibility while accurately highlighting movement on the surface against clutter and in extremely poor visibility conditions means that the Anubis's fire control system or allied forces will have maximum accuracy for the use of weapons systems, even in complex and chaotic situations, in the poorest of conditions. GXN-990 provides a continuous observation capability, maximizing detection resolution, even to the point of being able to accurately pinpoint enemy troop movements on foot on land or the movement of small, hand-launched drones.

SFT-1221, Sensor Fused Targeting Array:

SFT-1221 is the most complete targeting and fire control system yet fielded on a MTD-designed warship. The SFTA, or Sensor-Fused Targeting Array is comprised of a network of four large ball turrets and four synthetic radar apertures, positioned near the top of the ship's deckhouse. All turrets are triple vibration isolated and stabilized, cryo-cooled and use argon/krypton filled, magnesium fluoride coated sapphire lenses for extreme image purity, outstanding low-light/zero lux performance and provide crystal-clear situational awareness in sensor fusion. SFT-1221 seamlessly integrates identification, targeting and fire control on an ultra-fine level, precisely accounting for all possible variables and bringing to bear a vast network of sensors to completely account for surveillance of the battlespace and also for present threats to the vessel. are triple vibration isolated and stabilized, cryo-cooled and use argon/krypton filled, magnesium fluoride coated sapphire lenses for extreme image purity, outstanding low-light/zero lux performance and provide crystal-clear situational awareness in sensor fusion.

The SFTA includes four 1.8 gigapixel Argus-IS visible light cameras for highly detailed deep-field imaging. Accompanying these cameras in the visible light category are four 19 megapixel, 1,538 frame per second high speed sensors capable of recording 6K resolution video in extreme slow motion. Four 8 megapixel, 17 frame per second UV sensors in the 190 nm to 400 nm range are accompanied by an extremely long range 1080p continuous wave EMCCD Infrared camera with zoom laser diodes in the 400/2,000mm format, which are manufactured by Ascendant Terra PTZ. Integrated fire control is provided by eight advanced 1.5 micron Coherent Doppler/LIDAR arrays. CDL uses dual summed beams operating spaced apart and at different frequencies to take extremely precise measurements of windspeed, particulate matter and other atmospheric variables between the vessel and the target. Paired to each CDL is a set of three 80mJ Laser Rangefinders, operating at 20 pulses per second at the 635nm wavelength. Each beam has less than .3 mrad divergence and the paired system is used to positively locate and track a target, even one moving at incredibly high speeds so that weapons may be brought to bear to counter the threat.

The SFTA includes four 1.8 gigapixel Argus-IS visible light cameras for highly detailed deep-field imaging. Accompanying these cameras in the visible light category are four 19 megapixel, 1,538 frame per second high speed sensors capable of recording 6K resolution video in extreme slow motion. Four 8 megapixel, 17 frame per second UV sensors in the 190 nm to 400 nm range are accompanied by an extremely long range 1080p continuous wave EMCCD Infrared camera with zoom laser diodes in the 400/2,000mm format, which are manufactured by Ascendant Terra PTZ. Integrated fire control is provided by eight advanced 1.5 micron Coherent Doppler/LIDAR arrays. CDL uses dual summed beams operating spaced apart and at different frequencies to take extremely precise measurements of windspeed, particulate matter and other atmospheric variables between the vessel and the target. Paired to each CDL is a set of three 80mJ Laser Rangefinders, operating at 20 pulses per second at the 635nm wavelength. Each beam has less than .3 mrad divergence and the paired system is used to positively locate and track a target, even one moving at incredibly high speeds so that weapons may be brought to bear to counter the threat.

NDA-1050, Multifunction Doppler Radar:

The primary navigation and weather sensor of the Anubis class is a rotating dome pulse doppler radar, concealed in the radar-transparent uppermost level of the ship's deckhouse. This system, which scans the sky to extreme ranges roughly a dozen times a second bombards the ship with high sensitivity, high resolution information which allows Testudo vessels to navigate even in the worst conditions and monitor changing weather conditions with a high degree of accuracy. This information is fused with information relayed on the communications network from other allied sources and the entire battlespace picture is displayed in rich, intricate, scalable detail through the ship's computer.

HMS-717, Hull-Mounted Sonar:

A warship presents a powerfully attractive target for a wide variety of potential enemies. The area of the vessel's greatest vulnerability, and also the arena in which a modern warship is expected to be least combat capable, is under the surface. To that end, a great emphasis was placed on the sonar capabilities of the Testudo suite. Housed in the bulbous bow at the ship's forefoot, the HMS-717 is a computer controlled solid state 6th generation synthetic aperture passive/active sonar, using the vessel's computer to provide ultra high resolution signal processing. Synthetic aperture sonar (SAS) is a form of sonar in which sophisticated post-processing of sonar data are used in ways closely analogous to synthetic aperture radar. Synthetic aperture sonars combine a number of acoustic pings to form an image with much higher resolution than conventional sonars, typically 10 times higher. The principle of synthetic aperture sonar is to move a sonar along a line and illuminate the same spot on the sea floor with several pings. This produces a synthetic array equal to the distance traveled. By coherent reorganization of the data from all the pings, a synthetic aperture image is produced with improved along-track resolution. In contrast to conventional side-scan sonar, SAS processing provides range-independent along-track resolution. At maximum range the resolution can be magnitudes better than that of side-scan sonars. The 717 uses extremely low frequency pairs of twinned inverted pulses in very shallow "sweeps" that narrow the band to minimize detection by nearby vessels, so a complete and extremely detailed picture of the seafloor and surrounding areas may be taken with little danger.

With a range of 50km even in deep water HMS-717 has the ability to use twinned pair pulses to "see" through underwater obscurants such as thermoclines, haze or bubble clouds. Even in the littoral, vessel commanders will be aware of objects on the bottom or nearby contours of the sea floor other vessels and even animals within a great range as though looking through a window out into the ocean. In the event of a torpedo attack on a Testudo equipped vessel, all passive arrays are switched off and active arrays are turned on at maximum power in the direction of both the attacking torpedo and the hostile submarine. This has the effect of blowing out the sonar array on the hostile torpedo and ship, which causes the enemy vessel and its weapons to lose target solution and very often, forcing the enemy submarine to power down its sonar array. The torpedo's sensitive guidance system very often malfunctions or is destroyed under such a directed energy attack, which the equipped vessel will use as an opportunity to evade and escape. In passive mode, Testudo equipped vessels use their passive arrays to replace the thousands of hydrophones common on so many classes. These broadband, ultra-high resolution sensors pick up the tiniest of resonances or disturbances in water; from a clam shutting its shell on the seabed kilometers away to whales turning silently in deep water or the hum of a diesel-electric submarine running only on batteries, Testudo uses supercomputer-driven digital signal processing to detect and classify as never before the world around it underwater by listening with great sensitivity. Sounds as low as 20 db can be heard at distances greater than 50 km, though the exact passive capability is classified.

With a range of 50km even in deep water HMS-717 has the ability to use twinned pair pulses to "see" through underwater obscurants such as thermoclines, haze or bubble clouds. Even in the littoral, vessel commanders will be aware of objects on the bottom or nearby contours of the sea floor other vessels and even animals within a great range as though looking through a window out into the ocean. In the event of a torpedo attack on a Testudo equipped vessel, all passive arrays are switched off and active arrays are turned on at maximum power in the direction of both the attacking torpedo and the hostile submarine. This has the effect of blowing out the sonar array on the hostile torpedo and ship, which causes the enemy vessel and its weapons to lose target solution and very often, forcing the enemy submarine to power down its sonar array. The torpedo's sensitive guidance system very often malfunctions or is destroyed under such a directed energy attack, which the equipped vessel will use as an opportunity to evade and escape. In passive mode, Testudo equipped vessels use their passive arrays to replace the thousands of hydrophones common on so many classes. These broadband, ultra-high resolution sensors pick up the tiniest of resonances or disturbances in water; from a clam shutting its shell on the seabed kilometers away to whales turning silently in deep water or the hum of a diesel-electric submarine running only on batteries, Testudo uses supercomputer-driven digital signal processing to detect and classify as never before the world around it underwater by listening with great sensitivity. Sounds as low as 20 db can be heard at distances greater than 50 km, though the exact passive capability is classified.

DEFENSIVE ARMAMENT:

A truly modern waship is considered to be a critical and highly lethal piece in the complex, evolving battlespaces of the 21st century. To remain a relevant, functioning, useful component of tomorrow's wars, Myrmidon's vessels needed to be designed with a truly world class defensive suite, unlike any ever fielded before. Testudo armed ships are better protected and more capable of carrying out their missions despite numerous, advanced threats from the most modern armed forces. To this end, a multi-layered defense with envelopes of passive and active protection was created, extending many kilometers from the vessel itself, creating the capability of placing large numbers of allied forces under its protective umbrella. These systems for protection of the Testudo-armed warship are outlined below.

1x Aspis Mk. II Gun Turret.

4x Aspis Mk. II Missile Turrets.

4x AIDEN C1 Illumination, Passive Turrets.

4x AIDEN C2 LRDEW, Passive Turrets.

4x AIDEN C3 IRDEW, Active Turrets.

400x AIDEN C4 SRDEW, Active Turrets.

Artificial Intelligence Defensive Energy Network:

Testudo warships utilize a network of ball turret pods organized along the top surfaces of the vessel's deckhouse to counter threats to the vessel and to deter aircraft and other possible hostile assets entering its zone of protection. This network is called AIDEN and the turrets fall into two categories, Passive Defense and Active Defense. All AIDEN turrets except for the Category-4 can traverse a full 360 degrees in the horizontal and the vertical; the first three turrets traverse as high as 180 degrees per second and are fully stabilized, while the much smaller Cat-4 turrets are fixed emplacements with 90 degree fields of fire. When a threat is identified, it may be in range of multiple turrets. AIDEN uses advanced intelligence processing to prioritize either individual or multiple turrets to "stare" in order to defeat the identified threat faster and move on to other threats, concentrating the power of multiple resources to defeat an incoming missile quickly. Multiple threat envelopes surround the vessel, with corresponding levels of response to violations of this battlespace. The various turret types are outlined below.

Category 1 Turret, Illumination - **4 Each.**

C1 Turrets use a 2.5 kilowatt, 150-million candlepower xenon arc lamp to illuminate aircraft, ground targets or large areas of land or water. This is useful both for navigation and for disorienting and deterring human targets or for a "soft deterrence" for aircraft approaching the Type-115. A high-intensity sapphire IR emitter to provide near-field infrared illumination for lights-off target identification is also fitted to these turrets, along with infrared IFF emitters and a 1064 nm Laser Imaging Camera for detection of enemy laser illuminators.

Category 2 Turret, Passive Kill LRDEW - **4 Each.**

The Passive Kill suite provides a 15 kilometer protection envelope for the Anubis class vessel. A 5,000mW diode-pumped solid state laser dazzler, a Directed Infrared Countermeasure (AN/AAQ-24V) and an Elta ELL-8222 Self-Protection Jamming Pod are integrated together to bombard an identified missile threat or enemy aircraft with a combination of radar, laser and infrared energy, confusing targeting systems and forcing a targeted threat to either self-destruct or veer off course. This comprehensive system has proven effective against all known laser guided, infrared guided and radar guided surface to air and air to air missile threats.

Category 3 Turret, Active Kill, IRDEW - **4 Each.**

For GPS Guided targets such as cruise missiles or unguided Rocket, Artillery or Mortar threats, the active kill suite provides a 10 kilometer envelope of protection around the Anubis class vessel. This system uses solid-state 300 kilowatt ceramic solid-state lasers to burn through and cause catastrophic failure of threats of all types. This ultra-fast and extremely powerful laser has proven extremely effective in real-world testing and in combination with the type's EOTS, can accurately hit targets as small as 60mm mortar rounds with an extremely high hit probability out to its maximum range while requiring only two seconds to transition from standby state to firing state.

Category 4 Turret, Active Kill, SRDEW - **400 Each.**

The C4 Turret uses liquid-cooled five kilowatt multicore ribbon high energy fiber lasers to produce pulse-coded directed energy, inducing immediate low order burning and deflagration reactions in explosives or fragmentation in kinetic kill munitions at a standoff distance. A disrupted munition may still strike the vessel with fragments or concussion, but it will not do so with its full force and is extremely unlikely to penetrate the skin. A series of distributed laser heads connected by multi band fiber bundles and single polarization flexible optical fiber arrays are embedded into the hull of the vessel across its entire length and generate both short-wave/long-wave pumped laser and long-wave laser pumped energy to destroy multiple threats from multiple directions at extremely high velocities simultaneously, as close as 10 meters and as far away as 1,000 meters.

Category 1 Turret, Illumination - **4 Each.**

C1 Turrets use a 2.5 kilowatt, 150-million candlepower xenon arc lamp to illuminate aircraft, ground targets or large areas of land or water. This is useful both for navigation and for disorienting and deterring human targets or for a "soft deterrence" for aircraft approaching the Type-115. A high-intensity sapphire IR emitter to provide near-field infrared illumination for lights-off target identification is also fitted to these turrets, along with infrared IFF emitters and a 1064 nm Laser Imaging Camera for detection of enemy laser illuminators.

Category 2 Turret, Passive Kill LRDEW - **4 Each.**

The Passive Kill suite provides a 15 kilometer protection envelope for the Anubis class vessel. A 5,000mW diode-pumped solid state laser dazzler, a Directed Infrared Countermeasure (AN/AAQ-24V) and an Elta ELL-8222 Self-Protection Jamming Pod are integrated together to bombard an identified missile threat or enemy aircraft with a combination of radar, laser and infrared energy, confusing targeting systems and forcing a targeted threat to either self-destruct or veer off course. This comprehensive system has proven effective against all known laser guided, infrared guided and radar guided surface to air and air to air missile threats.

Category 3 Turret, Active Kill, IRDEW - **4 Each.**

For GPS Guided targets such as cruise missiles or unguided Rocket, Artillery or Mortar threats, the active kill suite provides a 10 kilometer envelope of protection around the Anubis class vessel. This system uses solid-state 300 kilowatt ceramic solid-state lasers to burn through and cause catastrophic failure of threats of all types. This ultra-fast and extremely powerful laser has proven extremely effective in real-world testing and in combination with the type's EOTS, can accurately hit targets as small as 60mm mortar rounds with an extremely high hit probability out to its maximum range while requiring only two seconds to transition from standby state to firing state.

Category 4 Turret, Active Kill, SRDEW - **400 Each.**

The C4 Turret uses liquid-cooled five kilowatt multicore ribbon high energy fiber lasers to produce pulse-coded directed energy, inducing immediate low order burning and deflagration reactions in explosives or fragmentation in kinetic kill munitions at a standoff distance. A disrupted munition may still strike the vessel with fragments or concussion, but it will not do so with its full force and is extremely unlikely to penetrate the skin. A series of distributed laser heads connected by multi band fiber bundles and single polarization flexible optical fiber arrays are embedded into the hull of the vessel across its entire length and generate both short-wave/long-wave pumped laser and long-wave laser pumped energy to destroy multiple threats from multiple directions at extremely high velocities simultaneously, as close as 10 meters and as far away as 1,000 meters.

Type-07 Mk. II "Aspis" Close-In Weapons System, Naval.

The Aspis Close-In-Weapons System incorporates two types of low-observable, electrically operated and stabilized turrets mounted on the missile deck of the equipped vessel. Integrated fully with the vessel's onboard sensor and fire control suite, the Aspis provides lethal coverage with guns inside 4,000 meters and with surface-to-air missiles inside 7,000 meters. This system is most frequently utilized as a "ship's gun" against small powerboats and other littoral environment threats while the SAM capability is a potent, but frequently last-ditch effort to protect against massed stealth aircraft or missiles which would otherwise overload the ship's AIDEN defensive suite.

Gun Turret: Pictured here. **One Each, Bow Placement.**

The Type-07's gun turret is a low-observable mounting with half-millimeter accurate electrical servos. While the platform is similar to the Russian AK-630M2, the servos are a Myrmidon design with 140 degree per second traverse to a maximum of -30 and +90 degrees in the vertical and 360 degrees in the horizontal at full speed. With both guns firing, the mount can produce up to an astonishing 10,000 rounds per minute to provide a cloud of fire against both missiles and aerial, naval or surface targets to an effective distance of 4,000 meters.

Missile Turret: Pictured here. **Four Each, Two Aft, Two Fore.**

The Aspis CIWS uses the Thales Starstreak Mk. II missile, which operates at Mach 3.5 out to 7,000 meters. The missile uses three kinetic-kill Tungsten darts which ride a laser designator to the target, penetrating the skin of an aircraft and fragmenting inside the aircraft, distributing sharp tungsten fragments through wiring harnesses, fuel tanks, cockpits and engines to efficiently kill enemy aircraft inside the seven kilometer radius. The launcher houses eleven ready rounds in a high-speed launcher.

Gun Turret: Pictured here. **One Each, Bow Placement.**

The Type-07's gun turret is a low-observable mounting with half-millimeter accurate electrical servos. While the platform is similar to the Russian AK-630M2, the servos are a Myrmidon design with 140 degree per second traverse to a maximum of -30 and +90 degrees in the vertical and 360 degrees in the horizontal at full speed. With both guns firing, the mount can produce up to an astonishing 10,000 rounds per minute to provide a cloud of fire against both missiles and aerial, naval or surface targets to an effective distance of 4,000 meters.

Missile Turret: Pictured here. **Four Each, Two Aft, Two Fore.**