This thread is not dead. Vault 1 will be replying from now on.

It may be passed on to another nation further. If you do not receive a reply within a week, consider it confirmed.

Comprising a line of weapons ranging from PDW to full-size assault rifles, sniper rifles and machineguns, R2 is a result of a cost-no-object project run by the Brotherhood of Steel to increase the firepower of an individual Knight to that normally only available to a fire team or a mounted weapon.

This goal has been successfully achieved through a convergence of modern technologies, not previously used in firearms, but well proven in specialized applications. At first limited to use by Brotherhood Knights, this weapon has now been offered for restricted export.

The key advantages of R2 include:

* Unified caliber. The same basic caliber (8mm) is used throughout the entire weapon range, from PDWs to machineguns, with different round length. This allows every soldier to use standard magazine, should the need arise.

* High power reserve. R2 has been developed as a response to increasingly heavy body armor developed by certain nations. It strips the enemy of any advantages of such armor by offering each serviceman a weapon that can penetrate any body armor with ease even at extreme ranges.

* Active recoil compensation. R2 includes a gas-operated system that actively counteracts the round's recoil and absorbs some of the energy, so even with high-power rounds, it remains more comfortable to shoot than even AR-15.

* Excellent ergonomics and moderate weight. Each weapon can be customized for the individual shooter, by varying the pistol grip position, trigger pull strength and length, and other characteristics. The use of a tensioned barrel system and innovative metal matrix composites makes R2 far lighter than any weapons of comparable firepower and comparable in weight to low-power rifles.

* A comprehensive accessory system. The chassis of R2 weapons contains 2 to 4 internal accessory channels and 3 to 6 rails for external accessories. An appropriately wide selection of accessories is offered, ranging from a semi-active sound suppression system to programmable airburst grenade launchers.

With this flexibility in every weapon, a shift to R2 could compared to introduction of assault rifles (which combined rifle and machinegun capability), offsetting the divergence that has occurred over the past forty years.

It should be understood that such performance does not come without a price, and it is not limited to procurement cost. R2 is a highly sophisticated modern weapon that bears only superficial resemblance to most contemporary rifles. The skill required for servicing it and infrastructure requirements for repairs are far in excess of those sufficient for legacy firearms.

A user can learn to shoot R2 in just a day, but prolonged training and experience are necessary to properly field service it and use all of its features. Such experience can not be gained during typical service terms in conscript or mercenary armies, limiting its practical use to fully professional militaries.

Furthermore, while it can work for a longer time without servicing than other rifles, mostly avoiding the need for field stripping, when the time for servicing comes, advanced maintenance infrastructure must be available. The rifle can only be safely disassembled in a cleanroom, with computer-controlled machines to perform operations such as lubricant replacement, and any repairs require a professional armorer specifically qualified to work with R2.

If such an infrastructure is not already present, it could be a reasonable decision to limit immediate adoption of this weapon system to special operations forces and elite units, since they would gain the most benefit from its features, while gradually preparing the rest of the military for the eventual shift.

The information below applies to all weapons of the armament system.

Currently the offers include:

- R2 Service Rifle

- R2L Lightweight Assault Rifle

- R2C Tactical Carbine

- R2GM General Purpose Machine Gun

- R2S Long-Range Sniper Rifle

- R2 Scout Lightweight Marksman Rifle (Upgraded R2.1 platform)

Detailed information on the variants can be found at the bottom.

Over the last 60 years, military technology has been evolving at a rapid pace, passing through two revolutions that have greatly changed the construction and application of nearly all weapons. Firearms, however, remained an exception to this rule. New technologies have been developed, tested, piling up, each adopted by one or another manufacturer, but never put together.

This situation lasted until 2006, when the accumulation of advancements finally broke through the dam of conservatism. The party responsible was the Brotherhood of Steel, an independent modern-day military order, dedicated to keeping peace in the wastelands of Vault Ten. Consisting of dedicated lifetime members rather than expendable grunts, the Brotherhood always kept its equipment up to the highest standard, and settling for the second best has never been an option.

Creating a partnership with the Aerospace Logistics Corporation, one of the leading manufacturers of deep space exploration systems, the Brotherhood has acquired access to technologies far in advance of those normally available to firearm manufacturers.

This opened an entirely new world of creative perspectives. Beryllium alloys, metal matrix composites and nanometer-structured fibers allowed for design with far more freedom in regard to materials strength, being nearly an order of magnitude more weight-efficient than conventional materials. Phase-shift cooling systems, providing nearly zero thermal resistance, revolutionized the approach to heat management. Fully computerized Aerospace Logistics manufacturing equipment, capable of nanometric precision, made possible new structural forms, not achievable with traditional manufacturing methods. Monocrystalline gold-indium conductors, solid-state molecular film supercapacitors and gallium arsenide semiconductors made self-powered and highly reliable electric ignition systems a reality. Seamless multi-structured carbon monocomposites created the possibility of nearly eliminating internal friction, and thus the need for lubrication, excluding major dirt and fouling related failure points from the design.

The end result of applying these technologies in a synergetic alliance is the R2 Infantry Armament System.

Despite having little in common with most rifles in technology used, R2 remains a firearm in principle. It still defeats its targets by launching a projectile at them, and still uses gas operation for its main action. While this is where the similarities end, it is enough to make the transition to R2 relatively simple, requiring few specific new skills, and allowing for a short learning curve for all personnel. The younger troopers will find R2 far more in touch with the times than other rifles and exceptionally user-friendly; while the experienced soldiers will appreciate its ability to precisely adjust to their shooting style and make full use of their marksmanship skills.

None of these capabilities come at the price of durability. The high-energy design of R2 puts high demands on the materials, and they are met with some of the best available options. Calling a weapon unbreakable is never proper, because for every nail there's a hammer; however, built predominantly of metal matrix composites, combining strength, ductility and light weight, R2 may be the closest firearms have gotten so far. One of the most significant reasons for weapon failures is cost-driven compromises in design and manufacturing, but no such compromises have been made with R2.

[ OOC: In case you're wondering, its Fallout equivalent is the heavily fictionalized version of XL70E3 found in Fallout 2. Now, if you are interested in some actual information rather than gun porn sales pitch, please read below. ]

R2 has been designed around the user from the very beginning, and ergonomics were thus the first priority. Whenever user comfort conflicted with ease of manufacturing, the situation was always resolved in favor of ergonomics.

First of all, the straight-lined shape, traditional for bullpups, has been rejected in favor of a more complex curved shape that incorporates an integral cheek rest. In order to avoid the weapon getting tangled, the exterior is almost entirely smooth, without any unnecessary protruding parts. One of the common inconveniences, external Picatinny rails, has been replaced by a combination of internalized VTS-105 rails and an internal accessory system.

To carry the weapon conveniently, it has to be as short as practical. To ensure that, most variants of R2 include a telescopic stock and a special collapsible flash hider that slides over the barrel; although the greatest contribution to length reduction comes from the bullpup configuration. A further length reduction is achieved by the boltless design applied. As a result, the complete high-power R2 rifle with its 630mm barrel is only as long as the XM177 carbine.

Each rifle's receiver, stock, trigger, grips, selectors, cheek rest, and other ergonomic parts are typically produced or installed individually, matching the user's anatomical measurements and shooting preferences. The customized dimensions include, among others, pistol grip position and angle, buttstock shape, dampening material choice, trigger configuration, cheek rest position, forward grip dimensions, fire selector switch position and shape.

Since the rifles are individualized, they are usually permanently configured as right- or left-handed, although some ambidextrous variants are also produced, mostly for gun shows and public shooting ranges.

Some ergonomic detail can be easily adjusted by the user after the rifle is built as well. The user can calibrate the entire curve of the trigger pull, select up to five pull settings and response to them, assign burst length and rate of fire to the three available controlled fire modes, or extend the selection up to nine fire modes. Every control on the rifle has adjustable sensitivity and resistance. The gas operation and recoil compensation system can be controlled on the fly, setting it to balance muzzle climb and vibrations to the optimal degree.

Last but far from least, the ergonomics are significantly improved by the four-stage active recoil compensation system (ARCS), which reduces the felt recoil of the powerful 8-millimeter rounds to that comparable to a conventional rifle.

R2 isn't the very first user-centered military weapon, however. This title belongs to the Steyr ACR, which has pioneered the highly ergonomic shape, roots of which can be seen in this rifle, and aggressive recoil reduction.

For the main action, R2 utilizes a vertically moving chamber, a concept previously used in Steyr ACR and R1. There is no bolt. The operation is very simple compared to most weapons. Caseless or cased ammunition is pushed inside the chamber from the rear or from the front. If a cased round is used or the caseless round fails, the brass is pushed out by the new round through the opposite side. The same operation can be done in reverse.

To operate the mechanics, two large-area pistons are used, a part of the recoil compensation system, located symmetrically around the barrel, usually top/bottom or left/right (depending on the specific model). No parts of the mechanism start to move until the round leaves the barrel entirely, avoiding negative effects on accuracy. Neither propellant gases, nor any other foreign objects do not at any point enter the receiver, which in an assembled rifle is actually airtight.

In order to simplify it, the mechanism is designed as inherently automatic, not select-fire. Single and burst fire is performed by not igniting the next round.

A special Accuracy Mode is available, where the mechanism is disabled entirely, and each round is cycled manually. This gives the accuracy advantage of a bolt action rifle with still rapid reloading.

Recoil is the main detriment to accuracy, the ability to fire on the move, and the ease of use. This problem would normally be exacerbated in the R2 due to the use of high-power 8mm rounds.

There are two measures of recoil: impulse and force. The impulse is generated by the round and can only be reduced very slightly, but force is what the shooter actually feels, and it is in inverse proportion to weapon's mass. Increasing the weapon's mass directly would be impractical, but it's possible to increase its effective inertia.

To achieve such a result, R2 utilizes a unique four-stage system, counteracting recoil on all levels where it is possible.

The first stage is fairly common - redirection of the propellant gases backwards. It is implemented by having the flash hider, the action and the sound suppression system integrated, all producing a slight muzzle brake effect. Thanks to sound suppression, this results in the effects of a muzzle brake without additional noise.

The second stage is the Active Recoil Compensation System itself, or ARCS, unique to R2. It consists of two, three or four (depending on the model) pistons in channels located symmetrically around the barrel, operated by gas pressure near the muzzle. These pistons, loaded with additional weights, accelerate backwards as the weapon fires, producing an impulse equal and opposite to the bullet's, negating it.

Since the pistons' cross-section significantly exceeds the barrel's, to work well with all rounds, the gas system is regulated on the fly by varying the electric circuit impedance.

The third stage is, while utilizing the same ARCS pistons, a distinct one, working on the later part of the cycle. Normally, recoil absorbing pistons would be pushed back by springs, transferring an increased impulse on rebound, and making the weapon jerk. This effect is avoided due to the electric Energy Recovery System, detailed below, which gradually slows down the pistons, and allows them to return just in time to match the selected rate of fire. The recoil energy is physically reduced at this stage, and recovered as electricity to charge the weapon's power system.

Finally, the telescoping stock is extended on two shock absorbers, which allow the entire rifle to slow down the transfer of force, recoiling in a more controlled manner, further reducing the force on the shooter and improving the steadiness.

Of most interest are the second and the third stage, forming the ARCS and ERS. Due to them, the weapon reacts to recoil in a different way than expected - most of the recoil is temporarily redirected to the motion of ARCS pistons. This increases the practical inertia, and in effect, the rifle behaves as if it was much heavier.

The exact increase depends on the system's tuning and the use of automatic or single fire. Even in the lightest tune, the effective inertial mass is increased from 4kg to 8kg for automatic fire or to 12kg for single fire, compared to a weapon that already has all conventional anti-recoil systems, including a muzzle brake and a telescopic stock.

In its heaviest setting, designed to deal with the recoil of 8-63 anti-materiel rounds, the effective mass can be increased further to about 20kg, with less than 1kg of actual weight added to the weapon (at 5kg total weight), although this does not apply to automatic fire.

R2 combines two methods of ignition: mechanical and electro-thermal. While the mechanical striker system remains perfectly functional in order to provide backward-compatibility with 7.62mm rounds, it is not normally used, unless explicitly switched on by the user.

Modern CL8 rounds are rather ignited with a low-energy electro-thermal system. A very small amount of air is simultaneously ionized, heated and shot at a high velocity from a special nozzle, igniting the propellant. Ignition units are located at the front and the back of the chamber, to allow for use of multiple igniters if burn has to be accelerated.

Electric ignition has a significant number of advantages over mechanical systems, which were critical in achieving the R2's level of performance.

* It is inherently reliable and easy to maintain, containing no moving parts.

* The lack of moving parts also contributes to accuracy, bringing the lock time (delay between trigger pull and firing) to zero. This is particularly useful in precision fire against moving targets.

* The plasma jet can ignite nearly anything that can burn at all, including rounds too damaged or too wet for regular primers.

* Propellants with extremely high ignition temperature can be used, preventing cook-offs even in a very hot chamber - even with caseless ammunition.

* Electric ignition provides a more even burn, allowing for slightly increased muzzle energy. High expansion velocity propellants further increase it.

* Primerless, caseless rounds can be produced at reduced costs, starting at just a few cents a piece, making very extensive training affordable.

While the ignition does require a small amount of energy, battery drain is not a problem, since R2 extracts the required energy from the firing process itself, as detailed below.

Whenever a weapon using any electrics is considered for infantry use, the question that sinks it is always "what if the battery dies?". But this argument doesn't apply to R2. With EER integrated, it eliminates the need for batteries altogether by producing its own electrical energy.

This does not involve any special fuel. The energy is taken from where no one will miss it - the weapon's own recoil and excess propellant gas.

As the ARCS pistons are pushed backwards by the gas pressure, their movement is opposed and slowed down by linear electric generators. The rare earth magnet arrays within the pistons produce a current in the generators as they move, and this current charges the embedded supercapacitors.

While it may seem complicated, this system is actually extremely simple, containing predominantly wires, and is in fact more reliable than mechanics, being non-susceptible to fouling, dirt, wear and tear, jamming, or any other problems inherent with complicated moving parts. No complicated semiconductor electronics that could glitch are involved - rather, it is more comparable to a piezoelectric-ignited cigarette lighter, with its weak point, the button, eliminated as well.

Apart from reducing recoil and improving accuracy, ARCS and EER have an additional effect of significantly reducing muzzle flash and noise. Both flash and noise are a result of high muzzle pressures. As the pressure is relieved and the excess energy spent powering the ERS, far less is left to produce demasking visual and sound effects.

While the energy extracted depends on the round, about 140 joules of energy can be produced with regular CL8-25 rounds, enough to keep all systems ready to fire for 18 hours even without the battery.

If all internal reserves are depleted, the initial energy to ignite the first round is provided by pulling the charging handle. It may need to be repeated a few times to also power other systems. Pulling the charging handle is also a simple way of checking the energy reserve: if it is good, the handle has very little resistance.

Forces and units who rarely have to open fire can switch the rifle to safety mode 2. In this case, counterweight springs are set to the lowest stiffness, and as the weapon is carried, the movement keeps it charging at a slow, but steady rate, similar to how an automatic watch self-winds.

In practice, as long as the auxiliary battery is in place, the shooter doesn't need to worry about the energy, since the battery will always have a reserve. It takes over a year of disuse for it to self-discharge fully, and as long as the weapon is fired or carried at least occasionally, it stays charged. Once the battery is discharged, it simply needs to be recharged; long-term degradation is minor.

In the older R1 rifle, the lack of a charging handle generator and its less efficient recoil power extraction prompted the use of a piezoelectric generator in the trigger and an automatic electric/mechanical ignition switching system. No such devices are needed in R2, with electric failures being rare, so the trigger pull is always smooth and comfortable.

The internal power generator only supplies the rifle and the sight. High-power accessories such as tactical lights rather have to carry their own batteries or, preferably, plug into the Central Accessory Power System.

Since the accessories tend to require more power than the EER can provide, the rifle is fitted with a more conventional battery-based power system, CAPS.

CAPS has four main components: the fixed battery, the replaceable auxiliary battery in the pistol grip, the universal inverter, and the power distribution controller.

The fixed battery is a set of non-aqueous nickel-sodium units, optimized with alloying elements for lower temperatures. This battery can operate between -80°C and 400°C, with no self-discharge at room temperature, and no damage up to 650°C (briefly). It can store up to 40kJ of energy when charged, and has a nearly unlimited cycle and storage time.

The auxiliary battery, described in more detail in the Accessories section, can be a rechargeable lithium-polymer type or a disposable lithium thionyl chloride battery. Additional batteries can be mounted on VTS-105 rails or in the internal slots.

Since the battery needs to be recharged, usually from external sources, a universal inverter unit is included. A universal inverter is an electronic power conversion device that can take in direct or alternating current of nearly any voltage, convert it to a fixed-voltage alternating current, and then produce from it a direct or alternating current of desired voltage. While the efficiency tends to be mediocre, it's of no concern in this case.

Two posts with wire rolls are included in the rifle, accessible after the stock is telescoped. Thanks to the universal inverter, they can be connected to any power source between 10 volts (car battery) and 3,000 volts (train power wires), and the inverter will produce the required current to charge the internal battery.

Furthermore, two output sockets are included. Selecting any voltage between 1.5 and 42 volts DC (in the DC socket) and 42 to 240 volts AC (in the AC socket), one can use it to charge the batteries in any electronic device.

As can be seen by now, the rifle has essentially two independent power systems: the supercapacitor with linear generators for ignition, and the battery system with a universal inverter for the accessories.

Sometimes, it's useful to transfer power between them. That's what the Power Distribution Controller is designed for. This programmable device can transfer excess energy from the generator to charge the battery, or, more commonly, do the opposite, charge the ignition supercapacitor.

All power needs are prioritized. The ignition system is given the first priority, the second being the scope illumination, and low-draw accessories like NVS, DACS, TS3 or ARD-02 a distant third. A further distant fourth and fifth are the high-draw systems like Electric Action Assist and accessories like tactical lights.

All versions of R2 include the Electric Action Assist and Control System - a set of actuators that can improve the operation of the main gas-powered action by smoothing its motion, assisting it if extra force is needed, seamlessly replacing the gas power in case of misfires, and automating normally manual operations. EACS actuators do not actually contact the moving parts, rather using the induction principle, and no main functions of the weapon require EACS to work.

One of the most noticeable features of EACS is rapid magazine change, that can be switched by a selector near the magazine ejection button to Full Assistance, Charging Only, or Off modes. If Full Assistance is active, as soon as the magazine is spent, it falls out of the gun, so the shooter only needs to insert the new magazine. Once inserted, the electric assist immediately charges the gun and prepares it to fire, the entire operation taking 4-5 times less time than when done by the shooter.

A feature harder to notice is the lack of jams with even the worst ammunition - whenever action can't proceed normally, EACS attempts to fix the problem, by ejecting a misfired round, or removing a damaged round that can jam the action by reverse motion. While not perfect, it saves precious time by correcting almost any problem without user interference.

EACS also allows the rifle to use automatic fire with rounds that normally do not provide enough, or any gas at all for the action to cycle, including in particular blanks, less-lethal ammunition, and very light rounds used with chamber adapters. Such use relies on the accessory battery to function, as no gas energy for the action also means no energy to be recovered by the ARCS, but since such rounds are usually fired in controlled conditions, this is acceptable and unavoidable.

To reduce the noise produced, R2 incorporates a modular internal sound suppressor. Its modules are located in channels around the barrel, alongside the anti-recoil system, and from 2 to 6 suppressor modules can be installed. The modules can be replaced with relative ease, giving the user a choice between long-lasting, automatic fire suitable, low-maintenance units that provide 6-12 dB of reduction, or highly efficient modules that can reduce volume by as much as 24 dB, but heat up rapidly and have a limited lifespan. Special variants of R2 can also be fitted with the Total Sound Suppression System, a unique development of the Brotherhood of Steel, that can make the rifle virtually entirely silent, although only in single shots at a low rate.

On R1, the sound suppressor was activated by twisting the flash hider. This created a certain inconvenience if the barrel was hot and the shooter wasn't wearing gloves. As a small but welcome improvement, R2 has an insulated ring that performs the same function while staying cold.

All internal suppressor modules operate on the principle of sound wave cancellation, converting their energy to heat in a series of chambers tuned to different frequencies. The heat is subsequently carried away by the rifle's phase-shift cooling system.

Among the issues encountered in R1 were small mechanical vibrations of the weapon at very high rates of fire, caused by the movement of the relatively heavy chamber. They affected the accuracy in multiple shots. In order to avoid such an issue in R2, the ULWC, or Ultra-Lightweight Chamber was developed, using the new forged composite technology.

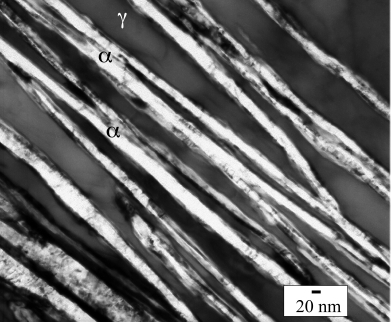

Regular carbon fiber composites, such as CFRP, use resins and polymers as their matrix. This is convenient, but the polymer's strength becomes the limiting issue to the overall composite strength. R2 utilizes the new forged metal matrix composite technology, originally developed for deep space probes. In such a composite, carbon fiber is encased in a metal rather than polymer matrix.

The matrix used, beryllium, is a metal known for rigidity, lightness, and high-heat performance - all characteristics perfect for use in a firearm. The application of beryllium is limited by its extreme cost, but it's still used where its properties are irreplaceable, such as in the Space Shuttle Main Engine.

While strong on its own, beryllium performs even better when reinforced with ultra-high-strength fibers. In this case, the fiber selected is multi-walled carbon nanotubes of 55 to 90mm length. Carbon nanotubes of such length are only produced in very small quantities and at an extreme cost, but their strength means only a very small quantity is required for the chamber.

To most effectively combine fibers with a metal, the chamber is built up gradually, in the forged composite process. A layer of carbon nanotubes is woven over a thin-walled beryllium tube, and covered by another thin layer of beryllium. The process is repeated to build up the thickness. Then, every few steps, the structure is cold-forged together under high pressure. The process is very slow and expensive; it takes 350 iterations to build the ultra-lightweight chamber with perfect cohesion between the metal and the nanotubes.

But the results pay off. The full-length 63-mm chamber, tested at a 450 ksi pressure, only weighs 12 grams, less than many of the rounds. Such a low weight decreases the weapon vibrations, allowing for very low spread in bursts. A chamber of the same strength made of high-strength steel or titanium would weigh over a kilogram, and be too bulky for the vertically moving chamber action.

To reduce heat buildup in such a light chamber, its inner surface is covered with a thin layer of a homogenous CMC, a ceramic matrix/ceramic fiber composite. Providing the same hardness, heat and friction resistance and heat insulation as ceramics, CMC also have their tensile strength comparable to their compressive strength, so they are not prone to cracking. The term "homogenous" means both the matrix and the fiber are chemically the same material, in this case a cubic boron nitride matrix, reinforced with nanoscale tubular boron fiber. Since the composite is anisotropic, it can rapidly conduct heat along the surface, keeping it safe from any thermal damage, but the heat can only penetrate across the tubular fibers at a very slow rate. The ceramic composite quickly releases the heat into the air, and rapidly cools as the chamber is vented, so the next round doesn't enter an overheated chamber. Low chamber mass also allows for a more rapid heat dissipation through contact with the action and the air inside.

Like its predecessor, the R2 rifle uses a tensioned barrel system, but with a composite structure throughout, in order to further improve the performance.

Ceramic lined barrels were considered for a while, but were ultimately rejected. Unlike the chamber, the barrel is heated by friction, not contact with hot gases, so a ceramic insulation would not keep it from heating. While ceramics have a great advantage over steel in wear resistance, if used as a liner, the difference in thermal expansion produces cracks over time, and the barrel can fail. It is more practical to replace or refurbish a steel barrel than to have a barrel with a theoretical lifetime of a million rounds that can fail unexpectedly at any time.

Therefore, a ferrous monocomposite was selected for the barrel, combining machining properties of steel with the strength of composites.

An iron-based material may seem out of place among the light alloys and carbon composites of R2, but the popular misconception of steel as a low-tech material is based solely on the cheap mild steels used in home appliances. In fact, the maximum theoretical strength of monocrystalline steel is second, out of known materials, only to carbon nanotubes, and reaches 24 GPa. Such strength can't be achieved in practice, but properly formed steel fibers have a strength as high as 5.5 GPa in continuous and 7.2 GPa in short form.

This steel is not cast or cut, but rather formed in a monocomposite form. A lesser-known form of composite materials, monocomposites consist of two or more allotropes of chemically identical or very similar substances. An example is ceramic fiber reinforced ceramic matrix composites, which use the same material in fiber form to reinforce itself.

A similar process can be done for steel, and actually has been, without any understanding of the process, done by many armorers over the time. Any surface-hardened steel is technically a monocomposite, consisting of two iron-carbon phases. Conscious application of the process, however, can produce far more consistent and impressive results.

Consisting of high-strength steel fiber overwrapping a ductile semi-bainite matrix, cold-forged together, the R2 barrel material has between 3 and 5 times the ultimate strength of conventional barrel steels. This allows a barrel section as thin as 1.5mm to withstand a pressure as high as 1.1 GPa (150 ksi), so the barrel is machined down to the optimal thickness. In practice, the barrel is given a 2x strength reserve, and the minimum thickness is 2mm in order to avoid local effects. And still, the entire 630mm barrel weighs less than 500 grams.

To stabilize the projectiles, variable geometry grooves are cut into the barrel. In the middle, they have what can be described as an intermediate cross-section between polygonal and regular rifling; this allows the gun to provide high accuracy to regular rounds, while minimizing the friction for high-velocity ammunition. Near the breech end, the cross-section is smooth and shallow, while it gets sharper towards the muzzle. Rifling twist depends on the rifle's purpose; while 1 in 250mm is common for general issue units, twists as tight as 1 in 100mm or as loose as 1 in 630mm are available. Barrels can be made with alternate groove profiles, all depending on the specific shooter's requirements.

Producing these variable-geometry grooves isn't possible neither with regular gunsmithing equipment, nor with hammer forging. To work around this restriction while minimizing the local stresses that could ruin the monocomposite barrel, a robotic micromechanical system is used. Instead of shear-cutting the groove at once, it rather uses thin diamond tools to remove a micrometric layer of material to a depth of hundreds of micrometers, effectively outlining the groove, and cutting the excess material off piece by piece.

Since a barrel of such relatively low thickness is not stiff enough for sniper-grade accuracy with high-power rounds, the designers had to resort to using a tensioned barrel structure, derived from benchrest shooting. Such a structure consists of two parts, the inner pressure vessel machined to the minimum thickness required to hold the pressure, and the outer tensioning system with a high moment of inertia that provides rigidity. A combination of these specialized elements produces a barrel that's lighter than even the lightest fluted barrels, but as stiff as a very thick bull barrel.

Normally, the tensioning system consists of a carbon fiber or titanium tubular sleeve. However, thermal requirements on one hand, and weight requirements on the other have called for better materials. In this regard, there's no competition to beryllium: while 2.6 times stiffer than titanium, it's 60% lighter, resulting in an impressive 9-fold stiffness improvement for equal weight. While its cost exceeds $4,000 per kilogram, only 270 grams are required to produce a tensioning structure with stiffness equal to a 3.5-kg steel barrel, resulting in an overall 80% weight savings compared to steel. The tensioning sleeve connects to the barrel by multiple frames, reinforcing it not only against bending under the stress of firing, but also against deformation under overpressure.

Outside, six stringers connect the rifle's chassis to the tensioning sleeve. The chassis is constructed of magnesium-lithium alloy, reinforced with non-woven carbon fiber using a physical vapor deposition process. This material was selected over beryllium for far lower cost, higher deformation limit, and being repairable, although it takes extreme force to even dent the MMC surface of R2.

The lightened version, R2L, substitutes some non-critical chassis parts for a carbon fiber reinforced polymer composite, like used in most modern assault rifles, which is lighter and cheaper, but not as resistant to damage.

In order to cool a barrel located so deep within the weapon, some special measures were required. This time, however, the solution is far less exotic, being based on phase-shift heat spreaders. A simple form of such heat spreaders is the heat pipes used in electronics cooling equipment.

In case of R2, the heat spreader is integral to the barrel. The tensioning frames are covered with metallic fiber, and the space between the barrel and the sleeve contains a small amount of phase-shifting cooling compound, creating a heat pipe. The sleeve itself and the walls that connect it to the outer chassis have micro-heatpipe exchanger plates inside, distributing heat all over the chassis.

To provide more rapid cooling of the barrel, these heat spreaders are complemented by a semi-active air cooling system. As the operating pistons are pushed back by the gas pressure, they displace hot air inside, which is in turn rapidly removed from the internal space. This is an improvement over R1, where all cooling was conducted through the receiver's outer surface, and the weapon could get dangerously hot during prolonged firing. R2 remains relatively cool at all but the hottest situations, and the hot air is directed away from the shooter.

Thanks to the power of the phase-shift cooling system, there's no need to change barrels even after prolonged continuous firing.

However, the older R1, despite using a less sophisticated but still effective system, has still been criticized for the use of a fixed barrel, for reasons concerning customization. This issue has been addressed in R2, and, although it is a workshop rather than a field operation, the inner barrel can now be removed and replaced. This allows for further individualization: marksmen can install barrels with a higher twist rate and groove profile, while others may opt for low-twist, low-profile rifling that sacrifices a bit of round stability in favor of higher muzzle velocities.

While most of the materials used are hard on their own, an increase in surface hardness is always welcome for a weapon, reducing wear rate and need for lubrication. For this purpose, a multi-layer carbon-based coating has been employed.

Just fifteen decades ago, the idea that diamonds could be synthesized would appear sacrilegious, if it wasn't so ridiculous. But only in a century, it became commercialized for technical diamond production.

A couple decades ago, the idea of diamonds existing in the form of a thin film was viewed as equally ridiculous. But a few years ago, the technology of growing synthetic diamond films has been refined for producing ultra-hard tools. In fact, without tooling using this technology, building R2 would cost even more than it does now.

To produce this diamond coating, a laser-assisted plasma deposition process is used, applying a combination of excimer, neodymium-yttrium and carbon dioxide lasers at multiple wavelengths. In a reaction zone shielded by an inert gas, a high-carbon gas mixture is directed at the coated part. Collimated laser beams are directed through the same magnetic nozzle as used for delivering the coating elements to the reaction zone. The energy provided by lasers near-instantly transforms the carbon into a layer of diamonds, its structure depending on the lasers used, energies involved, and initial gas pressure.

Such synthetic diamond finish is applied to all action parts of the rifle. In order to ensure minimum friction, it has three main layers: crystalline diamond next to the pre-treated surface, nanocrystalline diamond over it, and an amorphous diamond-like material on the surface. This structure provides an exceptionally flat surface, yet without a tendency to 'glue' to other similar surfaces.

Apart from reducing wear over an order of magnitude compared to conventional finishes, the multi-layer diamond coating has another important feature, provided primarily by the final layer: friction reduction. Even without any lubrication, it has less friction than an oiled raw stainless steel weapon. Thus, the need for lubrication is greatly reduced. The only lubricant used anywhere in the rifle is a mil-range layer of solid graphite lubricant.

For up to 120,000 rounds, the rifle parts' finish and initial graphite lubricant can maintain low friction as they are, provided there has been no dirt ingress removing the lubricant. After approximately 100,000 rounds, the parts' finish should be restored in factory conditions. To ensure the finish lasts and the lubricant is always properly applied, approximately every 10,000 rounds (20,000 maximum) old lubricant should be removed and the parts covered with a very thin layer of graphite lubricant. This is not a field procedure, but neither is it ever an urgent one, since the finish on its own provides an ample reserve for operation.

On the outside, the rifle is finished with a ceramic-based powder coat. Similar to polymer powder coats, but cured at a higher temperature, it provides a durable, no-gloss surface of the desired tone. Parts that contact the shooter have multi-layer coating to thoroughly insulate him from internal heat.

R2 has been built with improved ease of field service and maintenance in mind, which were notoriously difficult with the R1. In this pursuit, R2 has achieved the feat of requiring even less maintenance time per shot than some traditional mechanically ignited weapons. There are no locking pins or other small components that can be easily lost, no narrow tubes that are difficult to clean, and, generally, few parts that require field servicing.

In order to disassemble the weapon, the user should fully extract the buttstock. Behind it, protected by rubber covers, there are two small levers that, when turned, unlock the side panel on the right side (or left in the left-handed variant). Once done, the panel slides back and can be removed.

It opens access to all user-serviceable components. The user can clean the feeding system, the dud ejection system, remove and clean the chamber, install chamber inserts, clean the ignition nozzles, check the basic electric system and the barrel cooling system. All this is done without actually disassembling the weapon or removing more than one major part at a time.

While the weapon has an extensive set of features, it remains highly reliable on the basic level due to the simplicity and straightforwardness of its vertically moving chamber action. All advanced auxiliary features operate separately from the firing system.

There are just two key moving parts in the action: the chamber that goes up and down, and the round loading piston that goes backward and forward, both powered by the gas piston. There is no bolt, no hammer or striker, no ejection step.

High energies in the electric ignition system make it self-cleaning, vaporizing any debris, and the temperatures can ignite even the worst rounds that can possibly be ignited. The weapon needs no batteries, since it generates more energy from recoil and excess gases than it consumes to ignite the rounds, and has backup generation from the charging handle. The main ignition system doesn't involve any complex electronics, and consists mostly of coils and stretches of wire, which concentrate the energy from the gas piston into smaller time and area.

As a last resort, the mechanical ignition system can be switched on, completely bypassing all electronics.

It is very difficult to jam the action of R2 without an unusual combinations of factors. Whatever is in the magazine is simply pushed forward. If the round fails, the rifle's Electric Action Assist seamlessly ejects it and feeds the next round. Due to its simple tubular geometry, anything that can be pushed into the chamber, can be pushed out.

If the electric action assist is on, dud rounds don't even require manual cycling. Theoretically, with EACS active, one could even insert a magazine filled with one round and dirt into the weapon, and it would cycle the dirt through, until it finds and fires that one round (although, of course, requiring cleaning afterward).

The reliability of additional systems is not as exceptional as that of the primary functions, but still high even by military standards.

All wiring inside the rifle uses a specialized alloy of gold, palladium, silver and indium, which is immune to corrosion, highly conductive, heat-resistant and mechanically strong. The connections are welded rather than soldered or screwed, eliminating them as weak points. It is protected by ceramic fiber composite insulation, which does not decompose up to 1200°C, unlike more common polymer insulation. Every rifle's insulation is is tested by submerging the open rifle in saltwater and having electric currents run through the cables, detecting even the most minor leaks.

Electronic components, where present, use Gallium Arsenide (GaAs) instead of silicon as their base. While less practical in most regards, GaAs is capable of working at far greater temperatures than silicon, in some applications up to 700°C, and can tolerate overloads as high as an order of magnitude. Of course, the actual electronics used are limited to far lower temperatures; nonetheless, it ensures there is no risk of permanent damage from overheating during automatic fire, as long as the recommended rates of fire and burst durations are not exceeded.

As mentioned above, the R2 rifle is designed to use caseless ammunition, but is also compatible with cased telescopic rounds. The feeding system is "ammo-blind": it works just the same whether there is a casing to extract or not, pushing out whatever remains in the chamber with the next round.

While the barrel diameter is fixed, the weapon is in fact capable of using three different calibers, switching between them by simply replacing the magazine. The trick is simple: all three calibers, CL8-25, CL8-40 and CL8-63, have all dimensions exactly the same, except for round length. Since the chamber is self-sealing, there is no need for round length to be the same as the chamber, and in fact the rounds can be any length between 25 and 63mm. Straight-through operation and caseless design prevent any problems with extraction, and the rifle's gas system is self-regulated through the ARCS, working equally well with lightweight and high-power rounds.

This feature is what allows the R2 to be either a light submachinegun or an anti-materiel rifle, whatever the shooter needs now - however, not at the same time, but with a magazine switch.

The specifications of CL8 caliber are as follows.

CL8 Caseless Ammunition

Diameter between grooves: 8.00mm +/-0.01mm

Diameter between lands: 7.80mm +/-0.15mm

Bullet diameter: 8.00mm +0.01mm -0.28mm

Complete round diameter: 14.00mm +0 -0.10mm

Minimum round length: 15mm

Maximum round length: Not limited, but 63mm in standard R2

Recommended round lengths: 16mm, 25mm, 40mm, 63mm, 80mm, 100mm

CT8 Cased Telescopic ammunition with the same dimensions is also available, but not recommended except for handloading purposes. The active cooling system of R2, heat-resistant construction and electric ignition system are explicitly designed to handle continuous firing of caseless ammunition without cookoffs or other issues.

Apart from its native CL8 rounds, all rear-fed versions of the weapon (including R2 and R2L) can fire 7.62x39, 7.62x51 and 7.62x54R ammunition. It requires opening the rifle and installing a special magazine adapter kit, which is supplied with the weapon and stored within the receiver until needed.

This feature is only intended for field use, if CL8 ammunition is not available, but 7.62mm rounds can be found in the field. It is not intended for reusing old ammunition stockpiles, neither for warfare, nor as target practice supplies, as the accuracy is degraded by over an order of magnitude. The only ammunition properly usable with R2 is 7.62mm blanks.

In older weapons, common concerns cited against caseless ammunition were vulnerability to moisture and risk of cookoff. Both have been successfully defeated in the R2 design.

The standard propellant used, VHITP X2, is a polymer-bonded explosive-based solid emulsion. It contains 80% of HMX, 8% of polyalkylene oxides, 3% of triol, 4% of diisocyanate, and 5% of elastomer binder, all energetic compounds with high thermal resistance. Since the solid phase is a hydrophobic polymer (rather than the main propellant as usually), ductile enough not to crack, the round has nowhere for water to enter. VHITP X2 rounds can be stored in water for months, and then simply wiped to remove it.

This propellant has a very high ignition temperature and is too insensitive to ignite with primers in regular weapons. However, it's easily set off when hit by the plasma jet of the electro-thermal system. Due to this, cookoff is virtually impossible at any practical temperature.

There's a wide variety of ammunition available for all intents and purposes, of different lengths and with different loads. One bullet type is described here.

To make the rifle effective against all targets, a special versatile bullet has been developed, used as standard for CL8-24, CL8-25 and CL8-40 rounds.

It consists of a mild steel body in a full polymer-coated copper jacket, rapidly thinning towards the tip, with a conical tungsten post in the center. The round's most important detail is the tip design, providing different behavior on contact with solids and liquids. Body armor creates compressive force that collapses the surrounding steel around the central post, providing for a hardened steel armor piercing shape. But, when entering a liquid, the pressure is distributed uniformly, creating very high drag within the cavity, pushing the bullet to rapid expansion.

These effects aren't combined; after penetrating hard armor, the bullet loses most of its expansion capability. However, the tungsten cone in the center, acting as a wedge, increases expansion in liquids, and the conical section behind the cavity helps to tear the steel, also providing for limited expansion after solid object penetration.

Overall, while the soft-target effectiveness of the versatile bullet is slightly lower than of an equivalent energy large-caliber bullet, the expansion effectively utilizes high velocity, saving weight. Performance-wise, it exceeds both 7.62x51 and .50AE in effectiveness, providing high penetration and expansion diameter reaching 35mm. The bullet delivers high terminal effect, known as stopping power, for either fast termination or rapid incapacitation with non-lethal shots.

This structure is illustrated below.