![]() by Virana » Sat Dec 22, 2012 8:40 pm

by Virana » Sat Dec 22, 2012 8:40 pm

![]() by Virana » Sat Dec 22, 2012 8:40 pm

by Virana » Sat Dec 22, 2012 8:40 pm

Please present any orders to the main storefront and refrain from posting in this thread. Thank you.

Berkeley XRAY™ — $100

Berkeley XRAY Tactical™ — $120

AccessoriesOMPP Domestic Manufacturing License — $100,000,000

- Soft case/cleaning cloth (comes free with sunglasses) — $20

- Headstrap — $20

Please present any orders to the main storefront and refrain from posting in this thread. Thank you.

![]() by Virana » Sun Dec 23, 2012 11:59 am

by Virana » Sun Dec 23, 2012 11:59 am

Please present any orders to the main storefront and refrain from posting in this thread. Thank you.

Warez Gen 4™ T-shirtWarez Gen 4™ Combat shirt — $160.00

- Short-sleeve — $40.00

- Long-sleeve — $50.00

- Long-sleeve, 1/4 zipper — $55.00

Warez Gen 4™ Combat pants — $200.00

- Warez Gen 4™ All-weather combat shirt — $200.00

Warez Gen 4™ Utility Jacket — $150.00

- Warez Gen 4™ All-weather combat pants — $310.00

- Warez Gen 4™ Utility pants — $150.00

Lightweight set (short-sleeve t-shirt, combat shirt, combat pants) — $350.00 — you save $50!

Midweight set (long-sleeve t-shirt, all-weather combat shirt, all-weather combat pants) — $510.00 — you save $50!

Utility set (short-sleeve t-shirt, utility jacket, utility pants) — $290.00 — you save $50!

1 set (all pieces of uniform) — $1,100.00 — you save $215!

OMPP Domestic Manufacturing License — 1,200,000,000.00 (price for 1 million full sets)

For any combination of components not listed above, discounted price is negotiable. If you would like to request such, please inquire as part of your purchase.

Please present any orders to the main storefront and refrain from posting in this thread. Thank you.

![]() by Virana » Sun Dec 23, 2012 1:33 pm

by Virana » Sun Dec 23, 2012 1:33 pm

Please present any orders to the main storefront and refrain from posting in this thread. Thank you.

Night operations configuration.

Mission documentation configuration.

Airborne operations configuration.

Building breaching configuration.

Stemix WRETCH High Cut — $980.00

Stemix WRETCH Maritime Cut — $900.00

Stemix WRETCH Low Cut — $1,200.00

Warez WRETCH Special Operator Cut — $1,500.00

Helmet AccessoriesFor any other accessories, please contact the United Republic DSAA.

- Up-armor side covers — $340.00

- Gunsight mandibles — $300.00

- Face visor — $120.00

- High definition helmet camera (side rails) — $260.00

- High definition helmet camera (MAS) — $400.00

- Airborne O2 mask — $150.00

- IR strobe light — $200.00

- Helmet cover

- Standard — $45.00

- Hybrid — $50.00

OMPP Domestic Manufacturing RightsStemix WRETCH High Cut — $980,000,000

Stemix WRETCH Maritime Cut — $900,000,000

Stemix WRETCH Low Cut — $1,200,000,000

Warez WRETCH SOP Cut — $1,500,000,000

Please present any orders to the main storefront and refrain from posting in this thread. Thank you.

![]() by Virana » Wed Dec 26, 2012 8:31 pm

by Virana » Wed Dec 26, 2012 8:31 pm

Please present any orders to the main storefront and refrain from posting in this thread. Thank you.

[OOC: I actually had the idea to make a body armor system just like this using nanomaterials after coming across it while doing research for another potential product for this storefront. When telling a friend about my idea, I was alerted that Lyras had also created armor based on this. After also discussing the situation with an individual closely tied to Lyran Arms, I was told that it was fine to develop such type of armor as long as I didn't just copy and paraphrase Lyras's writeup. In order to prevent this, I actually avoided reading Lyras's article until I finished the history portion (integral to my research). After reading through Lyras's article I decided to edit in a few points in the history section regarding the relationship between Lyras and ApNano, including that entire last paragraph, to provide perspective in this whole situation ICly. Any correlation between this article and Lyras's occurred either purely by chance or by the concept of "great minds think alike".]

Figure 3A: Ballistic Protection Standards, U.S. National Institute of Justice Standard-0101.06

Type I

(.22 LR; .380 ACP)No longer part of the standard.

- 2.6 g (40 gr) .22 caliber long rifle lead round nose (LR LRN) at 320 m/s (1050 ft/s)

- 6.2 g (95 gr) .380 ACP full metal jacket round nose (FMJ RN) at 312 m/s (1025 ft/s)

Type IIA

(9 mm; .40 S&W; .45 ACP)

- 8 g (124 gr) 9 mm FMJ round nose (FMJ RN) at 355 m/s (1165 ft/s)

- 11.7 g (180 gr) .40 S&W FMJ at 325 m/s (1065 ft/s)

- 14.9 g (230 gr) .45 ACP FMJ at 259 m/s (850 ft/s)

Type II

(9 mm; .357 Magnum)

- 8 g (124 gr) 9 mm FMJ RN at 379 m/s (1245 ft/s)

- 10.2 g (158 gr) .357 Magnum Jacketed Soft Point (JSP) at 408 m/s (1340 ft/s)

Type IIIA

(.357 SIG; .44 Magnum)

- 8.1 g (125 gr) .357 SIG FMJ Flat Nose (FMJ FN) at 430 m/s (1410 ft/s)

- 15.6 g (240 gr) .44 Magnum Semi Jacketed Hollow Point (SJHP) at 408 m/s (1340 ft/s)

Type III

(rifles)

- 9.6 g (148 gr) 7.62×51mm NATO M80 ball at 847 m/s (2780 ft/s)

Type IV

(armor piercing rifle)

- 10.8 g (166 gr) .30-06 Springfield M2 armor-piercing (AP) at 878 m/s (2880 ft/s)

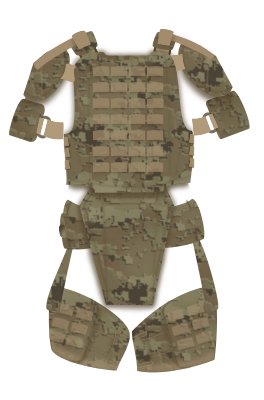

MPBAS Personal Armored Vest + Modular Blast Belt (no inserts) — $1,700.00

MPBAS Adaptable Carrier System + ACS components + Modular Blast Belt (no inserts) — $900.00

MPBAS concealed body armor — $600.00 for any protection level

NTS Scutum™ Enhanced Personal Protective Inserts (EPPI) set (Type IV+) — $1,500.00 — Restricted Level 2

Dyneema® HB80 Personal Hard Armor Inserts (PHAI) set (Type III+) — $800.00

Supplemental Armor Components — $1,000.00 (complete set)Personal Armored Vest complete set (PAV + MBB + SACs + concealed armor + inserts)

- Lower abdomen panel — $200.00

- Shoulder pads (pair) — $150.00

- Bicep pads (pair) — $150.00

- Forearm pads (pair) — $100.00

- Thigh pads (pair) — $200.00

- Armored collar guard — $200.00

Adaptable Carrier System complete set (ACS + MBB + SACs + concealed armor + inserts)

- with Scutum EPPI inserts — $4,600.00 — you save $200! — Restricted Level 2

- with Dyneema HB80 PHAI inserts — $4,000.00 — you save $100!

OMPP Domestic Manufacturing License on MPBAS set (no inserts) — $4,200,000,000

- with Scutum EPPI inserts — $4,000.00 — Restricted Level 2

- with Dyneema HB80 PHAI inserts — $3,300.00

OMPP Domestic Manufacturing License on Scutum EPPI inserts — $1,500,000,000 added to price of set

OMPP Domestic Manufacturing License on Dyneema HB80 PHAI inserts — $800,000,000 added to price of set

Please present any orders to the main storefront and refrain from posting in this thread. Thank you.

![]() by Virana » Sun Dec 30, 2012 5:21 pm

by Virana » Sun Dec 30, 2012 5:21 pm

Please present any orders to the main storefront and refrain from posting in this thread. Thank you.

Berkeley HEATRAY™ FR assault gloves (pair)OMPP Domestic Manufacturing License — $200,000,000.00

- Fingered — $85.00

- Half-fingered — $80.00

- Fingerless — $75.00

Please present any orders to the main storefront and refrain from posting in this thread. Thank you.

![]() by Virana » Thu Jan 10, 2013 6:57 pm

by Virana » Thu Jan 10, 2013 6:57 pm

Please present any orders to the main storefront and refrain from posting in this thread. Thank you.

Advertisement

Return to Global Economics and Trade

Users browsing this forum: No registered users

Advertisement