Prototype in Desert Camouflage

*Images by Animarnia*

***

STATS

Height: 3 m

Length (hull): 7.6 m

Width (hull): 3.8 m

Width (track): 609 mm

Weight: 70 tonnes

Crew: 3 (Commander, Driver, Gunner)

Engine: 1x WMC-501 Multi-fuel Flat-12 Diesel Engine; 1,300 kW

APU: 1x WMC-222 Multi-fuel Flat-4 Diesel Engine, 102 kW

Power/Weight: 25.25 hp/tonne

Transmission: WMC-55 Automatic Epicyclical Transmission (5 fwd gears, 2 rvse)

Suspension: In-Arm Active Hydropneumatic Suspension

Ground Clearance: .40 m

Maximum onroad Range: 600 km

Max Onroad speed: 80 km/h

Max offroad speed: 60 km/h

Armor: Adversus Tank Armor

Anti-spall: Dyneema

Countermeasures: Self-Sealing Fuel Tank, Internal Foam Fire-Suppression System

Autoloader: Theophilus Autoloading System

Main Armament: 1x LY414(LA) 140mm 50 caliber, high-pressure, ETC smoothbore

Coaxial Armament: 1x 50 mm LY106 compact autocannon

Secondary Armament: 1x Model 50 HMG

Tertiary Armament: 1x SX24A1 Caseless machine gun

NBC system: 1x STANAG 4447 compliant system

Unit Price: 12 million standard dollars

Background

The M-21A2 Valkyrie was started when the very successful A1 variant was no longer seen as being sufficient against international tank developments. The A2 contains multiple improvements, which will maintain Lamonian force overmatch in tank on tank engagements. Partially seen as a response to the “A2 project” (as it became known at LAIX Arms), information has been obtained from Lyran Arms (on an unofficial level), stating that they will soon begin their LY8 Doberman Main Battle Tank. This bit of news only added to the urgency felt that Lamoni would be left behind in tank development, if something was not done. Accordingly, the Lamonian Chamber of Deputies, as well as the Lamonian Congress, and President Stinson, rushed through a bill, which provided the initial funding for the A2 project.

Being surrounded with other nations known for designing quality tanks (Lyras, Macabees, Sumer, etc), the Free Republic needed a tank that would be able to stand up to all current and (projected) future threats from these, and other nations. The widespread proliferation of Lyran tanks was also a major source of concern for the Lamonian Joint Chiefs of Staff. While the M-21A1 had fulfilled this highly desired niche, the A2 would face down a new generation of armored threats, keeping the high standards that had gone into the A1.

As with other tank projects throughout history, improvements were made even after the first prototype models of the A2 were produced. These improvements resulted in the finished product of the M-21A2 project.

Co-Axial Armament

The primary coaxial weapon (left coaxial slot) used on the M-21A2 is the Sumerian/Lyran LY106. The LY106 is a compact medium autocannon, which fires the increasingly common Fedalan 50x300 mm caseless telescoping round, which was first seen as the primary weapon of the Sumerian PIV-30 AICV. The LY106 is chain operated, and externally powered by a 4 hp motor from the failed LY105 30 mm cannon. The LY106 uses a system of sprockets, groves, and clutches to feed, load, and fire rounds from either of two ammunition drums. The choice was made to only use two (instead of four) ammunition drums in order to save both space and weight, as was done in the A1. There are 300 APDS rounds stowed for the autocannon.

Much of the LY106 is made of Titanium, which is expensive, but is also considerably lighter than its steel volume/strength equivalent, which allows for the weapon's mounting to be considerably lighter. With the weapon being firmly secured to the turret while used in the coaxial role, the lighter elements of the receiver assembly don't adversely affect the weapon's recoil characteristics. As with all weapons on the A2, the LY106 benefits from Sensory and Ballistic Calculatory suites.

The barrel of the LY106 is 50 caliber, putting it 2.25 m from the end of the receiver, and it is chrome-lined in order to improve durability, and allow for the provision of higher-pressure propellant charges. Three rates of fire can be selected; including Semi-Automatic, Low Rate Automatic, and High-Rate Automatic. These allow single shot, 50 rpm, and 100 rpm for the Automatic modes.

The LY106 is designed to provide the A2 with effective, reliable, and accurate firepower for the destruction of most medium-armored threats, including helicopters, IFVs, APCs, and even many MBTs outside of the frontal arc. In the anti-armor role, the LY106 is considerably more potent than the Bushmaster series autocannons previously in use by LAIX ARMS designs.

Tank Launched ATGMs

The A2 gains GLATGM capability with the LA-422 Comburo missile. As the GLATGM designation denotes, this missile can be fired from the main gun of the A2. With a penetration rating of 1,096 mm RHAe, as well as Laser Beam Riding guidance, the Comburo is a formidable weapon on the modern battlefield. The Comburo GLATGM variant has a maximum range of 8 km. SALH guidance was considered, but was rejected, as Laser Beam Riding guidance methods are harder for an enemy to detect with laser warning gear.

For customers who might insist on keeping the traditional box launchers that have been standard on the last two variants of the Valkyrie series, they can be used on the A2. This enables the modified tank to fire the LA-420A1 Havik II ATGM, which has a maximum range of 18 kilometers, when ground launched. A heavier missile than the Comburo, the Havik II attains a penetration rating of 1,400 mm of RHAe, and has a tri-mode (94 GHz Millimeter wave active radar homing, imaging infrared, and semi-active laser seeker, with INS/GPS) seeker head, enabling it to more effectively defeat enemy attempts at ECM. The Havik II also carries an active radar jammer, allowing it to bypass the MMW and radar frequencies commonly used in Active Protection Systems.

Secondary Armament

The A2 also carries a Model 50 Heavy Machine Gun, from AIM Incorporated in Amastol. Chambered in 15x120 mm, this is the new HMG of the Lamonian Military. The vehicle mounted variant is used in the A2, with electric solenoid firing. Lightweight, Accurate, Heavy Hitting, and able to operate independently of major logistics; the Model 50 is an excellent example of combat flexibility and lethality. Permission has been obtained from AIM Incorporated to offer this weapon for export with the A2, but the receiving nation does not have permission to resale the weapon, unless such is negotiated with AIM Incorporated. A flat fee of eighty percent of the price of each Model 50 HMG sold/used in this manner is paid to AIM Incorporated as royalties for use of this weapon. If required, a different HMG can be placed into the right coaxial slot, but this must be specified when ordering the M-21A2.

Tertiary Armament

A 6.25x48mm Caseless, SX24A1 Caseless machine gun is mounted on a modified SWARM Remote Weapon System (made in conjunction with the Thales Group in the United Kingdom), utilizing the CM3 LR Optronics system from France's Sagem Défense Sécurité.

The CM3 LR was obtained under license, and uses a Thermal channel, a visible color channel, and a "full eye-safe" Laser Range Finder in order to provide the Fire Control System with the information that it needs to make every shot from the SX24A1 count. The Thermal channel alone can operate at ranges of up 8.1 km against MBTs, while the visible color channel and laser range finder have a 5 km range.

The CM3 LR can receive external power supply from 18-32 V, and consumes merely 34 Watts after cooling down. The SWARM/CM3 LR system can operate in climatic conditions from -33 C to 60 C, and incorporates a de-icing system. The SWARM/CM3 LR system can also operate in both daylight and night time darkness, can traverse a full 360 degrees (with a minimum tracking speed of 0.01 degrees per second), and provides image stabilization. The system is controlled by the gunner, but can also be used by the tank commander while the gunner uses his other systems.

Round: 6.25x48mm Caseless

Rate of fire: 800 or 1400 rpm selectable

Barrel length: 600mm

Rifle twist: 1:5.5 right hand

Overall length: 1370mm (stock extended)/ 1120mm(stock folded)

Weight (gun empty): 7.9kg on bipod

Magazine: Linked ammo belt

Fire modes: Safe/Semi/Restricted automatic/Fully Automatic

Mechanism Description:

The SX24A1 machine gun uses a long stroke gas piston gas operated revolver mechanism built around a 3 chamber cylinder. On a round being fired and gas entering the gas tube or the charging handle being worked, the operating rod moves backwards, initially engaging the rammer which feeds a round backwards from the link less feed box into the cylinder, as the operating rod continues backwards it unlocks the breach block, rotates the cylinder to bring the new round into the firing position and draws back the striker assembly. After reaching the rear of its movement the operating rod is pushed back by the return spring. On its way back the operating rod relocks the breach block, retracts the rammer and forces a piston through the previously fired chamber, this piston serves to force air through the chamber to cool it, remove any debris and eject any unfired ammunition. In semi automatic mode the striker assembly stays locked in its rear position until the trigger is pulled or in automatic firing moves forward immediately firing the round milliseconds after the breach block as been locked although a slight delay is imparted when the weapon is operated in the reduced rate of fire or “restricted automatic” mode.

Construction:

Most of the body is manufactured from high grade polymer with most components of the mechanism being milled from steel or high grade titanium alloys; the barrel consists of a lightweight titanium overwrap with a Molybdenum-Rhenium (Mo-Re) liner for increased service life and general wear resistance.

Features:

The SX24A1 features a highly effective muzzle brake which acts to reduce felt recoil by as much as 35%, this combined with the already acceptable recoil forces of the ammunition make the weapon very comfortable to shoot. In terms of modularity the SX24A1 features the latest version of Crookfur's advanced Rail Interface System (RIS). Known as Smart-RIS (SRIS), not only does it allow power to be supplied to any compatible device from a large high capacity battery in the pistol grip but it allows attached “smart” devices such as aiming systems and programmable grenade launchers to interface with one another without the need for additional wiring. As a machine gun with a ferocious rate of fire it is vital that the barrels be quickly replaceable to prevent overheating. To remove the barrel a button inside the front hand guard is depressed, to disengage the barrel lock and using the attached handle the barrel is rotated counter clock wise and pulled forward for removal, the replacement barrel is fitted by sliding it backwards into the weapon and then rotating it clockwise to lock it in place.

Ammunition:

The SX24A1 uses the new advanced 6.25x48mm CFC caseless round. Standard loading is a 130 grain boat tailed FMJ round that offers exceptional performance out to more than 780m (round is supersonic to about 1000m) Alternative loadings include a reduced recoil 113 grain round or an extended range Penetration Performance Improved (PPI) 150 grain round.

Active Protection System

The A2 uses the Advanced Missile Counter Measure System III (AMCMS III) APS. A vast improvement over the AMCMS II APS used on the A1, the AMCMS III provides protection when it is needed the most.

LAS sensors are designed to provide crews with situational awareness of laser emissions and other warning signs associated with anti-armor threats, and allow rapid countermeasure response. They form the basic building block of the system, and include an Active Defence Computer (ADC), and a number of laser and other warning sensors.

AMCMS III provides 360° azimuth coverage of a platform by using four LAS-310 Laser Warning Receiver sensors, and four flat panel Dual Band (X/Ka band) radar antennas, capable of operation in low visibility conditions. Full hemispherical coverage capability can be provided by adding a LAS-500 top attack Laser Warning Receiver.

The AMCMS III can provide dynamic external fire protection while moving at speeds of up to 80 km/h. After the sensors, the second tier of protection provided by the AMCMS III comes from two banks of eight (66 mm) grenade launchers, one bank to a side. These grenade launchers can be loaded with VIRSS, HE, and chaff grenades; all of them designed to protect the A2 from various threats.

By means of the grenade launchers, AMCMS III denies a threat the opportunity to effectively engage the protected system by interfering with acquisition, tracking, ranging, or guidance. This is achieved by using a combination of sensors, and 66 mm grenades.

The third tier of protection is a hard kill system. Named Averto, the hard kill system consists of three six-round High Speed Directed Launchers (HSDL), firing rocket propelled grenades, which detonate their Composition H6 High Explosive charge in proximity to the threat, with the intent of either knocking the threat off course, or destroying it outright. Averto is a Latin word, with a meaning of “to turn away, avert, avoid, turn back.” The range of the Averto hard kill interceptors is on the order of 5-15 meters. This short range is intended to reduce possible friendly casualties, while removing the threat. After the threat is detected by the Ka band radar, the relevant directional hard kill countermeasure unit is rapidly traversed, at a rapid slewing rate (over 600 degrees/sec.), aiming at the direction of the threat, and the rocket propelled grenade is then fired.

The ADC senses which launcher tubes are loaded, and controls and fires the grenades intelligently, taking into consideration the wind conditions, threat direction and vehicle directional motion relative to the threat. The ADC also informs the crew of the direction of the threat, allowing them to engage the source of the threat, if the tank crew so chooses.

The countermeasure deployment can be selected to be manual, or fully automatic. The warning sensors will detect the threat direction and the controller will execute the appropriate selected countermeasure actions to defend the platform against the detected threats, in automatic mode.

The system is effective against RPGs, anti-armor missiles, recoilless rifles and tank or anti-tank guns firing HE, HESH and HEAT ammunition. The system also offers significant reduction of a Kinetic Energy (KE) projectile's penetration capability. It can also be used manually for rapid obscuration of an attacker’s line of sight in ambush situations, and is fully redundant, due to the different types of sensors employed in the system.

Fire Control System

Contracting with Sequoia Electrodynamics in the Lamonian allied nation of Etoile Arcture has resulted in the Adepto Fire Control System. Adepto is a Latin word, with a meaning of “to obtain, get, acquire.” Considering that the purpose of a Fire Control System is to acquire a fire control solution, Adepto is properly named for the job that it is tasked with. Standard laser filtered tank optics are included with the entire package, but the electronics fit for Adepto is first rate.

The gunner utilizes a Gyro stabilized panoramic Cadmium Zinc Telluride (CdZnTe) EO/IIR sensor, with 3x to 9.5x zoom. A Kigre Incorporated inspired, High Repetition Rate Q-switched, InGaAs laser diode pumped, Er:Glass laser rangefinder is also utilized. The two-mode laser range finder can be operated in a pulsed mode (for normal range finding), or in a constant stream, capable of being used to paint an enemy target to assist guided missiles, like the Comburo GLATGM, or the Havik II ATGM.

Er3+ doped phosphate laser glass exhibits high thermal shock resistance in combination with superior laser performance. The laser and thermo-mechanical properties of this new glass make it an excellent material to meet the demanding requirements of high repetition rate laser systems. Also included in the gunner’s sensor suite, is a weather sensor on the turret rear, GPS/INS gear, a ballistic computer, a cant sensor, and a muzzle reference sensor.

Taking a cue from the MCA-7 series of tanks, the LA-16 radar can share its information with the fire control system, which can be useful in the presence of smoke, or other battlefield obscurants. Terrain that is likely to obstruct the tank’s path can also be picked up, so that the driver knows the locations to avoid in the area (or similarly, the location of cover).

The Tank Commander has his own Gyro stabilized panoramic CdZnTe EO/IIR sensor, which shares all of the functions that the gunner’s sensor has. The driver has four such sensors, one in each quadrant of the tank. These CdZnTe EO/IIR sensors allow the driver to complete his job more efficiently, displaying obstacles that cannot be seen by the driver’s standard optics. If battle damage renders the driver’s sensors inoperable, the driver can rely on standard optics, while the Tank Commander’s sensor data can also be displayed on the driver’s video screen (which also displays all information related to the driving task, including fluid levels, and other information), which was purpose developed.

Borrowing from fire control measures designed by the Koreans for the K2 Black Panther, and implemented in Lamonian and allied MBTs, Lyran Arms and the Varessan Commonwealth's VMRDB developed a built-in trigger-delay mechanism.

Earlier platforms can be found to, despite all other fire control methods, miss their target when they fire their main gun, and hit a slight bump at the same time, a problem exacerbated, as would be expected, by movement at high speeds and/or across uneven terrain. The designers of the K2 anticipated this situation, and generated a solution for it by installing a laser emitter-receiver assembly linked to the FCS, a concept that was brought across for implementation in the main gun on the A2, and is now commonplace on Lamonian MBTs.

The emitter is fitted near the top of the barrel, with the receiver being placed at the barrel's base. The weapon can only be fired when the laser receiver array is exactly aligned with the emitted laser. To illustrate, if at the point of firing, when the gunner presses the trigger, linked as it is to the fire control system, the vehicle comes upon an irregularity in the terrain at the same moment, the laser will find itself pushed off the receiver by the sudden movement, and the FCS will delay the round's ignition until the beam reorients to the receiver again. As the barrel shakes up and down, the FCS will automatically fire off the gun when the laser finds its mark, and the barrel is judged to be on target. This system, combined with an advanced gyro-stabilizer, static pendulum cant-sensor and powerful fire control system, dramatically improves the vehicle's capacity to engage targets while moving at speed, even across broken terrain.

Another feature of the Adepto Fire Control System is the digitally displayed Gunner’s sight data. Modified from a similar system found on the Leclerc tank, the TS-70 Gunner’s Sight provides the tank gunner with useful information in an easy to follow format.

***

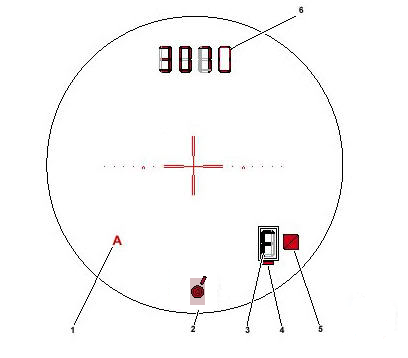

Diagram of the A2’s TS-70 Gunners Sight Digital Display

1 - System error message(s)

2 – Sensor/main gun position compared to front of tank hull

3 - Selected ammunition: F = APFSDS, H = HEAT, T = Training, S = Smoke

4 - EO or IIR mode display: Red = EO, Green = IIR

5 – APS radar on/off indicator: Red = off, Green = on

6 - Measured distance to target (meters)

7 - Aim point in the form of a cross

***

While this digital display can be affected by battle damage, it was decided to include the technology for the purposes of streamlined presentation of vital data to the gunner.

Adversus Tank Armor

During the course of the development of the Adversus Tank Armor which would be used on the A2, different armor concepts came up that could be used for future projects (i.e., Cross-wise oriented NERA panels).

--------------

Exote

Aermet 100

Resilin

Aermet 100

Composite Sandwich Panel

Aermet 100

Resilin

Aermet 100

Composite Sandwich Panel

Aermet 100

Ti-6Al-4V

U-3Ti alloy DU mesh

Ti-6Al-4V

SiC encased in Ti-6Al-4V

Ti-6Al-4V

Chassis

Anti-spall

--------------

Adversus is the latest in the LAIX ARMS line-up of armor solutions for tanks.

Adversus starts with Exote, which is rated as being effective against small arms armor piercing rounds (including 15 mm armor piercing rounds). The Exote layer is expected to deal with small arms fire and shrapnel from enemy weapons fire. Exote is Titanium Carbide ceramic particles in a metallic matrix. In this case, the metallic matrix is RHA, making it ductile, which greatly improves its multi-hit capabilities while preserving typical ceramic terminal ballistic properties -- high hardness and ablation. Because the ceramic has been suspended in matrix form instead of sintered together, it is cheaper than ceramic tile armor arrays, while providing calculated protection levels equivalent to a 1.77x thickness efficiency, and 2.25x mass efficiency, compared to RHA alone. This process means that Exote is classified as a Metal Matrix Composite, or MMC. Exote-Armor was invented and first manufactured by Exote Ltd., a Finnish corporation.

Upon impact by an armor-piercing round, Exote’s Titanium Carbide particles wear down the round via ablation, until the round is effectively turned into dust. Exote also spreads out the energy of the round, and distributes it over a larger area, thus fully neutralizing impact. The damage area is only 20-30% larger than the caliber of the hit, and the rest of the plate will still remain protective. This makes Exote a multi-hit armor, which provides excellent protection from small arms, with a lighter weight than RHA alone. The Exote is also used to contain the rest of the armor package.

Lamonian innovations in the form of extruded para-organic resilin are also used. Resilin is an elastomeric fibrous compound found within the musculature of insects. To quote Dr Chris Elvin of Australia's Commonwealth Scientific and Industrial Research Organisation;

“Resilin has evolved over hundreds of millions of years in insects into the most efficient elastic protein known...”

***

Resilin shown under UV at 360nm

***

Using genetically modified E.Coli bacteria, the CSIRO team was able to synthetically generate a soluble Resilin protein, based upon the cloning and expression of the first exon of the Drosophila CG15920 gene. By means of a CSIRO-patented process, the resulting resilin rubber was shown to have structurally near-perfect resilience, with a 97 percent post-stress recovery. The next-nearest competitors are synthetic polybutadiene ‘superball’ high resilience rubber (80 per cent) and elastin (90 per cent). The cross-linking process itself is remarkably simple. It needs only three components - the protein, generally lactose, or a near analog, a metal ligand complex, ruthenium in this case, and an electron acceptor. The mixture is then flashed with visible light of 452 nanometers wavelength to form the polymer - within 20 seconds, the proteins will be cross-linked into a matrix with remarkable tensile strength.

Like it's Acerbitas (and Acerbitas-B) cousin, the Resilin used in Adversus is intended, as with NERA generally, to warp, bend or bulge the Aermet 100 plates upon impact. As the plates move, bullets are subjected to transverse and shear forces, diminishing their penetration, and shaped-charge weapons find their plasma jets unable to readily focus on a single area of armor. In the case of segmented projectiles, the transverse forces are less pronounced, compared to unitary variants, but the movement of the plate essentially forces the projectile to penetrate twice, again lowering total impact upon the platform protected.

The Resilin components are layered with Aermet 100 plates. The Aermet plates are angled, as penetrators striking angled plates will bend into the direction the plate is facing. This action on the part of the penetrator serves to significantly reduce the impact of the penetrator itself, as the penetrator expends energy on this bending motion, instead of being allowed to focus all of its kinetic energy on a single spot on the armor.

Aermet 100 alloy features high hardness and strength, coupled with high ductility. Aermet 100 alloy is used for applications requiring high strength, high fracture toughness, high resistance to stress corrosion cracking, and fatigue. Aermet 100 is more difficult to machine than other steels; Aermet being specially graded martensitic steel, and requires the use of carbide tools.

Composite Sandwich Panels are used both to increase the structural integrity of the armor, as well as to catch fragments that are created by enemy fire. The outside of the panels are composed of one centimeter thick plates of Aermet 100 alloy. One such plate is placed on either side of the panel. The interior of each panel consists of a three centimeter thick honeycomb of hexagonal celled, thickness oriented Aermet 100, where each cell of the honeycomb measures six millimeters across. Each hexagonal cell is filled with a mix of sintered Titanium Diboride (TiB2) ceramic tiles, and vinylester resin. This adds additional ceramic protection to the armor.

Ti-6Al-4V is a very popular alloy of Titanium. Designed for high tensile strength applications in the 1000 MPa range, the alloy has previously been used for aerospace, marine, power generation and offshore industries applications. Ti-6Al-4V offers all-round performance for a variety of weight reduction applications. It is used to sandwich the Depleted Uranium mesh, encase the SiC ceramic, and as the majority of the armor after that.

As chemically pure Depleted Uranium is very brittle, and is not as strong as alloys, U-3Ti alloy is used for the DU mesh. This alloy has a density of 18.6 grams per cubic centimeter. The alloy displays higher strength, and less brittleness than chemically pure Depleted Uranium.

Silicon Carbide encased in Ti-6Al-4V comes after this, with the Titanium alloy being used to encapsulate the SiC ceramic, as well as assist in hydrostatic prestressing, which is known to extend interface defeat. The SiC is isostatically pressed into the heated matrix; which more securely binds the ceramic into place.

Interface Defeat is a phenomenon observed when a hypervelocity penetrator strikes a sufficiently hard ceramic. The penetrator flattens its nose against the ceramic without penetrating into the ceramic for up to several microseconds, with penetrator material flowing laterally across the face of the ceramic until the ceramic starts to crack. As soon as cracks form, the lateral flow stops and penetration resumes. This effect is also called "dwell" in some publications. Silicon Carbide is excellent for producing this effect.

More Ti-6Al-4V is used as the bulk of the armor after the encased SiC, which has a superior mass efficiency relative to RHA, while its thickness efficiency is a bit lower (about 0.9:1).

The chassis is located behind this, with Dyneema being used as a spall liner. In Lamonian Main Battle Tanks, the chassis would likely consist of RHA. As Adversus will also be exported on a case-by-case basis, the chassis composition will undoubtedly change for export customers.

Most of the armor is concentrated on the frontal arc, with the sides also being covered, but to a lesser degree. The rear of the tank (like all tanks) is protected by RHA. Where logically applicable, Lyran designed Hauberk ERA is used to increase the protection levels of the tank. This includes use of Hauberk on the tank’s roof, which helps to protect the A2 against top attack munitions.

'Hauberk' shaped-charged explosive reactive armor is fitted as standard (though can be removed), designed to destroy (or at the very least severely degrade) hostile munitions, be they HE-based or kinetic penetrators. 'Hauberk' is available from the Lyran Protectorate, at no extra cost, and has been designed specifically to take advantage of research into explosive reactive armor carried out at the Lughenti Testing Range.

Owing considerably to its 'Rainmaker' ancestor, 'Hauberk' differs from 'Rainmaker' in two ways. The first change is a shift in the formation of the explosively formed penetrators of the defensive system, from directly opposing the projectile (firing along the same axis as the most likely threat at any given armor location) to a slanted system, angling (approximately) 45degrees up. The new system not only leaves 'Hauberk' considerably more compact, but dramatically improves its effectiveness against kinetic munitions of all forms.

The 'Hauberk' HERA system is composed of “bricks” making each “brick” easily replaceable once used and allowing the system to be fitted to AFVs already in service. The “bricks” are lightweight (at around 3kg) and this allows them to be positioned on as many areas of the tank as needs require.

An Aermet 100 Mine Protection Plate has been incorporated onto the underside of the A2, which offers protection from mines, and IEDs. This protection is in addition to the crew seating, and other protection measures. The turret front and sides are fitted with wedge-shaped add-on armor in sections, which can easily be replaced by field workshops if hit or, at a later stage, be replaced by more advanced armor. Aermet 100 alloy provides the outer casing, with a layer of Resilin to work against CE threats. U-3Ti alloy DU spheres encased in an Aermet 100 matrix cause KE rounds to yaw, reducing their penetration. The “wedge” armor is backed by more Aermet 100 alloy plating.

Propulsion

The main engine of the A2 is an air-cooled diesel 1,300 kW flat-12 multi-fuel engine. A "flat" engine contains pistons that are all relatively horizontal. There are two banks of 6 pistons, one of the banks located on each side of the single crankshaft.

This configuration allows for the flat-12 to be wider, yet lower in height, compared to a standard V12 engine. This is somewhat offset by the need for a higher mounting height in the engine bay to provide clearance for the exhaust system (6 runners on either side).

Most flat-12 engines are classified as a 180 degree V engine instead of a Boxer engine, because flat-12 engines have two pistons sharing a single crank pin.

While flat-12 engines have been used in Formula One and Endurance racing in the past, the design was largely abandoned for those uses because of the properties of wing-cars. The wide and flat layout of the engines obstructed the airflow, and was considered "obsolete."

Other than the layout of flat engines, they are generally considered to function at the same levels as their V layout counterparts.

Similarly, an air-cooled diesel 102 kW multi-fuel flat-4 engine is used as the A2's APU. This APU can power essential systems should the main engine fail; allowing the A2 to limp out of the line of fire. When not needed in this role, the APU provides power to move the turret, as well as the 240 V outlets inside of the tank. This outlet allows the user to charge equipment ranging from gun sights, to any other rechargeable device.

A bank of Lithium-Ion batteries are also used in the A2, for those times when more electrical power is needed.

Energy/weight: 160 Wh/kg

Energy/size: 270 Wh/l

Power/weight: 1800 W/kg

Charge/discharge efficiency: 99.9%

Energy/consumer-price: 2.8-5 Wh/US$

Self-discharge rate: 5%-10%/month

Time durability: (24-36) months

Cycle durability: ~1200 cycles

Nominal Cell Voltage: 3.6 / 3.7 V

The APU also provides power to the aforementioned battery bank, which can be used to silently propel the tank, with an electric drive. The vast majority of the time, the main engine runs the tank, but the battery bank coupled with the electric drive can silently propel the tank over short distances. This “silent drive” can confer tactical advantages such as being able to stealthily move up on the enemy, but can also be used to great PR effect, being able to move without angering the neighbors, while in the city.

Signature Reduction Measures

There is a second air intake that is used to force outside air through a forced air radiator, where it is mixed with the exhaust in order to reduce the IR signature of the engine's exhaust. This system can be switched off in NBC conditions in order to preserve crew health, and the serviceability of the tank.

The forced air cooling of the exhaust evenly reduces the temperature of the exhaust, thus making the A2's IR signature harder to detect.

Another method by which the detection signature is reduced is through use of the Lyran-designed and manufactured 'Warshroud' advanced multi-spectral camouflage netting system. Based heavily on the Ukrainian 'Kontrast', 'Warshroud' dramatically reduces the detection ranges against known radar, infra-red and visible-band methods. The 'Kontrast' system was developed at the Institute of Automated Systems in late 2002, and was designed to address a notable and growing problem. High-potency modern weapons are able to engage ground vehicles at any angle, from great ranges, by day or by night, irrespective of weather, and with a potency that was becoming increasingly difficult to counter. The Institute's researchers faced a real challenge and, moreover, it was decided to develop a single solution, one that would take into account all noted factors and be implemented within the weight and size limitations.

In approaching this task specialists at the Institute of Automated Systems decided to proceed from the key idea behind the design of high precision weapons. High-precision, high-lethality systems universally require integration with means of detection, which of necessity requires the design of sensor sets and target locators, and the implementation of effective scanning capabilities across several adjacent or near-adjacent visible and invisible spectra, including visible light, close and long infra-red waves, and laser scans (in the infrared, millimeter and centimeter wave bands).

The developers of Kontrast took an ordinary camouflage net as the base and, utilizing the latest technological innovations, turned it into a new generation signature-reduction product to combat the sophistication of modern radar systems and other contemporary military reconnaissance means. The result was the development of a surprisingly effective solution.

Developed countries traditionally have utilized a wide variety of signature reduction technologies, many of which include various after-manufacture coatings. The technical requirements of such coating are very high - their reflection capacity must be below 20 dB in a wide range of bands. This factor forced the Ukrainian – and later Lyran – research teams to examine new physical methods for reducing or amplifying reflection of radar waves to achieve effective electromagnetic concealment. With this goal in mind, the 'Kontrast' developers tried to find materials with absorptive and reflective characteristics for attenuating and amplifying electromagnetic waves. Experiments generated a series of composite materials with superb characteristics for greatly diminishing the wave reflection contrast between the protected object and its background.

'Kontrast' simultaneously employed both absorption and targeted reflection of electromagnetic waves. The array of material used within the netting the product, each of which featured at least one of the said qualities, allowed protection from a great range of known target location means. 'Kontrast' tests have repeatedly shown its superiority across a wide range of battlefield conditions to analogues from Sweden and Britain, whether the concealed unit is moving or stationary.

'Warshroud' built on 'Kontrast' by the integration of signature reduction techniques in the IR spectrum pioneered by the LDPCU multi-spectral camouflage. The resultant product takes nearly twice as long to produce, due to the difficulty in applying a coating (which had been done away with under 'Kontrast') to the camouflage netting. Attempts are being made to shorten the 'Warshroud' manufacturing process, but it is somewhat of a moot point. Production as it stands is more than capable of keeping up with the manufacture of the vehicles utilizing 'Warshroud'. The system's visible suppression includes, as with most camouflage nets, terrain-appropriate textile strips, which are soaked in a dielectric polymer that can absorb and scatter electromagnetic waves. The textile pieces are made of non-reactive, radar transparent fabric.

In 2002, tests run using 'Kontrast' on a T-84 determined that the ability of hostile weapons to lock onto a vehicle dropped nine-fold compared to an unshrouded vehicle. It was further established that T-84 MBTs fielding 'Kontrast' dropped out of visibility range of viewing devices at distances over and including 500m.

'Warshroud' builds on this, with additional substantial reduction in detectability of targets in infra-red, radio-thermal and radio wave bands. Improvements in synthetic and parasynthetic textiles have also reduced the inherent radar return in the material which binds the net together, along all detection envelopes.

'Warshroud' has repeatedly demonstrated excellent resistance to various external factors while keeping its camouflaging characteristics intact – a factor very quickly determined to be a critical capability of the system. Tests had tanks equipped with a 'Warshroud' run at their tops speeds in off-road conditions, in woods and deserts, while similarly equipped IFVs conducted amphibious landings. In all cases, the signature reduction capabilities of the equipment were unreduced to any appreciable degree. All elements of 'Warshroud' are resistant to fuels, lubricants (gasoline, diesel fuel, lube oil) and detergents. Furthermore, spinning off from research conducted into the LDPCU once again, the shroud is made of self-extinguishing materials, ensuring that flames cease to burn free of subsequent glowing, once the fire source is removed.

'Warshroud' itself consists of a number of modular components that can be put together to create a masking surface of any size and shape, with colors matching any field environment in any season.

It is currently expected that existing AFV stocks will be retrospectively fitted with 'Warshroud', as a means of contributing to the ongoing attempts to reduce detection footprints across all relevant bands.

While not part of the Adversus armor system, the M-21A2 also incorporates a method for improving the acoustic impedance of Epoxy Resins. The process used has succeeded in producing a castable and high modulus acoustic dampening material, which absorbs acoustic energy.

Relative to soft rubbers and the like previously used for acoustic damping, the polymer (called “Amitto”) has a high modulus of elasticity; that is, Amitto is stiffer and, therefore, better suited for applications in which some stiffness is required. One prior acoustic-dumping material contains lead, and is produced by casting into blocks that must then be machined to desired sizes and shapes. The release of lead particles during machining poses a toxicity hazard. In contrast, Amitto has little toxicity and can be cast in molds to final sizes and shapes, without machining.

It is not been possible to obtain a desired combination of high modulus of elasticity (E) and high damping in a rubber or a similar single-component material for the following reasons:

1. A rubber or similar material typically undergoes a glass-to-rubber transition in a temperature range characterized by a middle temperature Tg (denoted the glass-transition temperature). It is well established that such a material dissipates vibrations more effectively at Tg than at higher or lower temperature but also tends to be relatively soft (to have low E) at Tg. A rubber or similar material typically undergoes a glass-to-rubber transition in a temperature range characterized by a middle temperature Tg (denoted the glass-transition temperature). It is well established that such a material dissipates vibrations more effectively at Tg than at higher or lower temperature but also tends to be relatively soft (to have low E) at Tg.

2. It is also well established that the rate at which acoustic energy enters the material is proportional to E1/2. Hence, if a material has low E, it may not absorb acoustic energy at a rate high enough to be considered an efficient damper, even at Tg.

While it is currently not possible for a single component material to possess high dampening ability, as well as a high value of E, it is possible for a two component material to do this. A higher-damping, lower modulus component is dispersed within a lower-damping, higher-modulus component. This principle underlies Amitto, in which two-component materials are synthesized following a phase-segregation approach common to that followed in synthesis of rubber toughened epoxy materials.

In Amitto, the higher-damping, lower-modulus component is a carboxy-terminated butadiene nitrile (CTBN) formulated to have a Tg at or near the intended use temperature, and the lower-damping, higher-modulus component is an epoxy. In the first step of the synthesis of the material, a CTBN or a suitable mixture of CTBNs is mixed into an epoxy resin (typically in a proportion of 1 to 3 parts of CTBN to 10 parts of epoxy by weight or volume) at a temperature of about 150°C.

Once the epoxy resin has become modified by reaction with the CTBN, it is cooled, and then mixed with the epoxy-curing agent (2-ethyl-4-methylimidazole). The curing reaction involves both cross-linking and gelling of the resin molecules. During the curing reaction, the CTBN component becomes segregated into a separate phase comprising discrete, approximately spherical rubbery domains, between 1 and 10 μm in diameter, dispersed throughout the epoxy resin. Because most of the volume of the material is occupied by the relatively high-modulus epoxy and the Tg of the rubbery domains occupying part of the volume is at or near the intended use temperature, the material can have the desired combination of sufficient stiffness and sufficient damping.

The amount of rubber added to the epoxy is low enough that the modulus of the resulting composite does not vary much from the unmodified and high modulus epoxy resin. This high modulus allows a larger amount of acoustic energy to enter the material, where it is absorbed by the rubbery component. The resultant material is non-brittle and when cast in place the material exhibits adhesion to many surfaces.

The resulting polymer is situated between the chassis, and three centimeter thick panels of Aermet 100, surrounding the crew compartment of the tank. The Dyneema spall liner is situated behind the Aermet 100 panels. This reduces the noise level inside of the crew compartment, allowing the tank crew to work in a quieter (and thus, more comfortable) environment.

The side skirts are composed of Resilin, encased in Aermet 100. These side skirts serve to both armor the road wheels against enemy fire, as well as vastly reducing the radar signature of the road wheels. The side skirts can be removed, if desired, maintenance being one example.

Countermeasures

Self-Sealing Fuel Tank

The fuel tanks of the A2 are designed to seal themselves when penetrated; most often by enemy weapons. The A2’s Self-sealing tanks have three layers of rubber, one of vulcanized rubber and two of untreated rubber that can absorb oil and expand when wet. In between these untreated rubber layers is a layer of composite foam for improved absorption and sealing performance. When a fuel tank is punctured, the fuel will spill on to the layers, causing the swelling of the untreated layers, thus sealing the puncture.

This makes a fuel tank explosion caused by enemy weapons fire less likely, therefore providing a further safety margin for the crew.

AR-AFFF Fire-Suppression System

The role of AR-AFFF is to cool the fire and to coat the fuel, preventing its contact with oxygen, resulting in suppression of the combustion. AR-AFFF is a fire-fighting foam that will still form a protective film in the presence of alcohols, being resistant to alcohols.

The system can be activated by either pushing a button on any of the consoles, or automatically (via EO/IIR sensor); allowing for maximum flexibility, and a system which cannot be fooled by matches, lighters, cigarettes, or red clothing.

Suspended Seating

AMAP-MPS is used for seating in the crew compartments of the M-21A1. AMAP-MPS was designed by IBD-Deisenroth Engineering, from whom usage rights were purchased.

AMAP-MPS (Multi-Purpose Seat concept) is a seat that can be mounted in the vehicle to support the non-injury of personnel. It is decoupled from the bottom and supports the body. The 5 point safety harness of the seat is adjustable and is equipped with a quick release. Both the seats, and the straps contain Dyneema fibers, allowing them to shield the crew from spall and fragments.

NBC Protection

A STANAG 4447 compliant filter is employed in order to provide protection from NBC threats. The filter provides NBC protection through a combination of HEPA media and impregnated carbon granules integrated within the same casework. This system is capable of providing 400 cubic meters per hour of fresh air in bypass mode. When the filter has been engaged, it is capable of providing 100 cubic meters per hour of filtered air. In case of a failure of the filter system’s electric pumps, there is a backup hand powered pump.

The air that goes through the system is sent into the heating/air conditioning system of the tank, allowing the crew to operate in temperatures ranging from -40C to 55C.

Overpressure is also employed, in order to keep NBC threats from breaching the interior of the tank. When the hatches are sealed, no outside air (or for that matter, NBC threats) can enter the tank, except through the NBC filtration system. Automatically engaging overpressure systems are a new feature, designed to enable the vehicle to be opened in hostile environs without compromising the internal atmosphere.

Suspension

As in the A1, the A2 uses an In-Arm Active Hydropneumatic Suspension. The purpose of this system is to provide a soft, comfortable, yet well-controlled ride quality. In the military sense, the tank uses In-Arm Active Hydropneumatic Suspension for better crew comfort, and also for increased firing accuracy. The suspension system fitted to the A2 also allows it to “stand,” “kneel,” or “lean” to one side, or the other. This allows the A2 to engage targets at more angles than the Valkyrie line of tanks has been able to do before, as well as being able to move over more types of terrain.

Inexpensive in mass production; for vehicles that would otherwise have a conventional power steering pump, In-Arm Active Hydropneumatic Suspension adds no new equipment and in many cases results in a lower unsprung mass. Equally, the same system pressure produced from one central pump is used for braking.

The same natural law governing gasses also ensures that the suspension's spring-rate (hardness) is continuously adapted to the weight it has to carry, and to infinite positions. For example, when the tank is standing empty, the pressure within the suspension spheres is in balance. If one crewman enters the tank, this pressure becomes higher by the value of his weight (the gas in the spheres compressed to an equal degree, i.e. has now become "harder"). The tank will have lost some height, so the self-leveling system immediately reacts and brings the car up to the predetermined ride height. The result is that the spring rate is kept constant, regardless of the load of the tank. In example, a tank with 3 passengers and full payload will be equally well controlled as a tank with just one crewman. With a steel-springed tank, either the tank would be set up to be comfortable with 1-2 crewmen, but getting too soft as more weight is added (becoming uncontrollable under full payload), or it would be too stiff with 1-2 crewmen and okay on full payload.

Battle Management System

Warrior III is a Battle Management System designed for battalions; accelerating mission planning, establishing a common and clear language across all combat elements, as well as distributing and enforcing areas of responsibility. It automatically updates and distributes intelligence, target information, and alerts throughout the battalion, and enables flexible planning and operation. LAIX ARMS contracted with Elbit Systems on the Warrior III BMS, making Warrior III a derivative of Elbit’s “Tactical Intranet Geographic Dissemination In Real Time” (TIGER) BMS system.

Integrated with on-board networked BMS computers, every platform becomes a networked sensor, and a shooter. Weapons can be slaved by remote users, to remote sensors, therefore empowering the system with more flexibility, faster operation tempos, effective closed–hatch combat, and employment of distributed and dispersed firepower without risking fratricide.

The network relies on broadband connections to receive and distribute information, thus reducing the overall demand for networking resources. Routing is determined by dynamically weighing various criteria including shortest path, hierarchy, and classification, priorities, connectivity, and channel capabilities. Each broker gathers subscriber's topics and areas of interest and disseminates this information when required. Each broker is responsible for a group of stations and servers, working as their mediator to the rest of the network. Placed at strategic nodes, some brokers are enhanced to perform as "gateways", supporting the network with inter-network connectivity functions. Such gateways are dividing the network into clusters thus reducing message flow while improving delivery time.

Another element of Warrior III is the Tactical Message Oriented Middleware (TMOM), providing seamless transfer of messages between C4I applications over different communications channels. Messages are dispatched by "store and forward" techniques routed through optimal, secured and economical paths. The system automatically retransmits undelivered messages and sends acknowledgements to assure delivery. Messages are automatically routed around or within any sub-net which has been temporarily disconnected from the tactical intranet to overcome intentional or unintentional service disruptions.

Warrior III supports thousands of independent users, empowering every user station to operate as a router, thus establishing ad-hoc routing paths throughout the battlespace. The network follows automatic and adaptive learning of optimal network topology to support self-forming and self-healing functions, enabling effective and reliable communications coverage for highly dynamic operations. Warrior III supports wireless communications including VHF/HF tactical radios, high capacity data radios, satellite links, wide area networks, wireless LANs and cellular communications. The system is protected by multilayer security protocols.

Warrior III integrates built-in navigation, and communications functions, fully integrated with the platform, on-board sensors, and weapons. The system allows Instant Messenger style communications between members of the battalion, and can be used to contact superiors (in one example, to request an artillery fire mission). For this function, the BMS ties in with the radio communications set present in the vehicle, while still allowing the radio set to be used for voice communications at any time.

Warrior III systems are embedded with simulation and debriefing capabilities, allowing realistic training, and further information distribution capabilities. The system enables combined training of live and simulated forces, at multiple locations and different levels (battalion, brigade and other units). The Warrior III BMS is also intended to be able to integrate with other BMS systems, which can be useful in allied and coalition warfare.

(Better than mine

(Better than mine  )

)