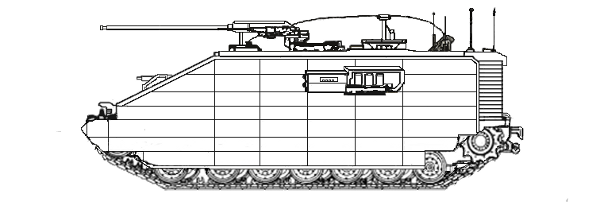

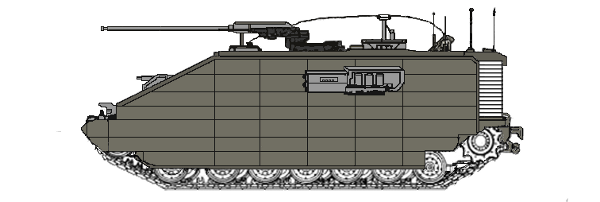

AY151B 'Javelin' Infantry Fighting Vehicle

AY151B 'Javelin' Infantry Fighting Vehicle

(click the picture for a larger-image version)

AY151B 'Javelin' Infantry Fighting Vehicle

(click the picture for a larger-image version)

- Basic information

- Designation: Sd.Kfz. AY151B

- Name: Javelin

- Role (within the Anago-Yohannesian Army): Infantry Fighting Vehicle

- Crew : 2 (commander, driver)

- Personnel capacity: 10

- Manufacturer : VMK AG - Land Defence Systems

- Place of origin : Anagonia-Yohannes

- Dimensions

- Length : 7.3 m

- Height (including roof of the turret) : 2.48 m

- Width (maximum) : 3.2 m

- Track Width : 460 mm

- Weight : 30 tonnes

- Performance

- Maximum (Governed) Speed : 107 km/h

- Cross Country Speed : 73 km/h

- Speed, 10% Slope : 48 km/h

- Speed, 60% slope : 33 km/h

- Acceleration (0 to 32 km/h) : 3.2 seconds

- Range : 571 km

- Operational Cruising Range : 462 km

- Manoeuvrability

- Trench Crossing : 309 cm

- Vertical Obstacle : 132.1 cm

- Fording without Preparation : 151 cm

- Fording with Preparation : 235 cm

- Deep Fording : Not capable of

- Suspension : VLT HPVS active hydropneumatic system

- Armament

- Primary : 1 x 30mm AY1A TCR autocannon (800 rounds) and/or 1 x 12.7mm AY14-HMG (1,200 rounds) (optional)

- Secondary : 2 x 6 Fragmentary Grenade Launchers, (optional) 8 x LA-420A1 Havik II BLATGM

- Power

- Engine : 700 kW (950 HP) FB-6TSDH diesel-electric hybrid six-cylinder boxer

- Fuel consumption: 1.2 L/km

- Transmission : Electronic Continuously Variable Transmission

- Power-to-Weight Ratio : 23.33 kW/t (31.67 hp/t)

- Armour and Protection

- Armour : Adversus AY151A Modified

- Glacis Hull: 180mm AT; 500mm RHAe vs KE; 716mm RHAe vs CE

Side Hull: 108mm AT; 300mm RHAe vs KE; 430mm RHAe vs CE

Rear Hull: 68mm AT; 189mm RHAe vs KE; 271mm RHAe vs CE - Protection : AY09 AFEDSS, AYHK10 ADS, and AY109 NBC/CBRN (NBCS) System of Protection

- Armour : Adversus AY151A Modified

- Export

- Price (per unit cost) : US$3,900,000.00 (three million and nine hundred thousand universal standard dollar)

- Domestic Manufacturing Right : US$5,200,000,000.00 (five billion and two hundred million universal standard dollar)

Background

The AY151B Infantry Fighting Vehicle, based on that of the AY151A, was conceptualised as a simultaneous Anago-Yohannesian armoured personnel transport and ground infantry fighting vehicle, and is strictly designated to act as a mean to both flexibily deploy Anago-Yohannesian personnel towards their respective operational field of tactical engagement and engage lightly armed opposing armoured fighting vehicles and ground infantry formations within its supporting vicinity.

The AY151B was famous for its crucial role during the War of the Four Emperors, where it commonly accompanied the Anago-Yohannesian state-of-the-art AY2-1E Panthera Tigris main battle tanks operationally, venturing deep into the opposing Haruspex and Tagmatian lines, nonetheless shamelessly known for its utilisation in the then multiple Anago-Yohannesian raid-and-run operations.

Agile and adequately armed and protected for its role, the AY15B, ever since its first utilisation and procurement domestically, has been loved by the majority of Anago-Yohannesian personnel for its easy-handling and extraordinary engine quality and capability.

Following approval by the Imperial and Royal Ministry of Defence, the AY151B 'Javelin' Infantry Fighting Vehicle is now available for export by virtue of VMK AG and its subsidiary international land systems contracting entities.

Primary armament

The primary armament of the AY151B is the Anago-Yohannesian 30mm AY1A automatic cannon, which hold eight hundred rounds, and is fully capable of providing a considerable direct vehicular tactical offensive role against opposing enemy infantries, dug-out defensive blocks, lightly armed trenches and built up areas, and hostile light armoured fighting vehicles.

The AY1A is an Anago-Yohannesian rapid firing automatic cannon, unique in that it utilised the initiation of telescoped cylindrical firing round, thereby increasing its efficiency and lethality. It incorporate the use of projectile feeding and fired projectile casing ejection ports, arranged axially from one another in its receiver, with the projectile firing position in between both the aforementioned ports. The end of the AY1A barrel is mounted to the receiver, and is aligned forward in relation to the projectile firing position.

The AY1A's rotor mean is mounted on the aforementioned receiver as a result of its rotation, and the round will axially be transported from its feeding position to its ejection port. Force is also provided by the rotor's connection to flexibly rotate it, consequently allowing the projectile to be transported from the feeding port to its firing position. The rotor will then be rotated simultaneously in a continuous manner alongside the AY1A's firing process.

The projectile holding cavity of the rotor will then retain the chamber, alongside its transverse aperture. The aforementioned phase will consequently result in a radial sliding motion of the rotor. As a result of the phase, the chamber will automatically initiate a camming motion, which will act as a connection towards the purpose of the chamber’s sliding radial rotation, together with that of the rotor, thereby allowing the projectile to be moved automatically towards its firing position. Each of the aforementioned rotation phase will automatically maintain the cavity’s firing position during the projectile firing motion, thereby increasing the gun’s flexibility and reliability.

Two differing, transversing projectile holding cavities are selected towards the system, and the chamber’s camming motion is initiated by virtue of the aforementioned two projectile holding cavities’ movement into the pre-selected firing position and phase in between the rotor motion phase, further reducing chance of operational error and dis-configuration of the gun firing motion. Pre-selected firing guidance of the projectile within its firing position is provided by the chamber camming motion described previously, which simultaneously will result in a longitudinal axis movement of the projectile’s holding cavities, automatically pre-selecting the right path, together with the barrel bore’s axis, each phase completed within a really short period of only 13 ms.

The AY1A is, unlike other within its calibre, conceptualised with operational efficiency and reliability in mind, with each phase and parts of its system accordingly built with emphasis being place in the easiness of field maintenance and technical efficiency, without sacrificing its lethality and field of firepower capacity. Sudden stopping of automatic firing operationally as a result of abrupt systematic errors found in most other automatic cannons has been avoided by virtue of the gun’s internal sliding mechanism and robust maintenance.

The AY1A is capable of elevating up to 45 degrees to engage any close-ground air support presence within its vicinity, and its utilisation enable the vehicle's gunner to utilise a range of close-in light support intensive rounds within its attached vehicle’s tactical field of operation.

AY151B IFVs of the K.u.K.117th Vanguard Support Company.

Whenever deemed as such necessary, additional mean of ground anti-personnel support which can be utilised alongside the AY1A TCR autocannon is the Anago-Yohannesian 12.7mm AY14-HMG heavy machine gun, which holds one thousand and two hundred rounds, divided by two equal stock accommodations, and are designated to occupy that of primary close-range field of light protection towards the front, flank, and rear vehicular side of the AY151B.

With a field of firing range of over 2,800 metres and 570 rounds per minute rate of firing, the AY14-HMG was conceptualised as a vehicle mounted machine gun, although it can still be utilised by ground infantries, but are nonetheless deemed as ineffective in such a role, a negative side-effect of its heavy weight of approximately 50 kilograms. The AY14-HMG is utilised by virtue of its recoil system, which incorporate a double sliding piece chamber together with a fixed barrel. The gun’s barrel extension, which utilised a systematic special holding cavity, will then be filled with the chamber’s left and right operations, with the left side operating as an ejector and the right side operating as the round’s main support.

The right side is also attached by an arched camming initiation which operates as a control and ejection accelerator, towards the chamber. The slide utilised as both the extractor and ejector mean is attached to the recoil spring, and is initiated as the round’s selection primary function, which of course, can be utilised as the round’s extraction system as well. The chamber’s second half is initiated as the accelerator of the round’s progress, and as a feeding belt mean to link it with one another within its cycle. A selector firing pin will then ignite once the process is completed, and this cycle will start all over again.

The cycle’s force is acquired from the motion in which the round is pushing itself against the operating holder, and pressurise both the two sides together up until the pressure is lowered to a sufficiently safe level. This will then allow both of the halves to be motioned back again. The accelerating role is seized by the cammed side, which will then fling the other side back together with it. Used rounds are ejected down, or to the left and right side, optionally to be chosen by each individual operating the gun. The gun’s feed mechanism can also be motioned towards both side, with as little changes to its operation as possible, thereby increasing the gun’s effectiveness in terms of manpower and time cost.

The aforementioned operation is considered to be quiet heavy in practicality, although the reason it was chosen was due to the fact that it generate an increasing rate of accuracy of the fixed barrel, and also will generate timesaving operation for a quick change of barrel. This moderately heavy barrel is utilised both to optimise surface area and decrease the operation cooling period and heat dispersion initiation. A front forward grip is also utilised and fixed to act as assistance towards the barrel’s change operation. It is also used to remove the need of protecting arm glove utilisation.

A dual trigger mechanism is utilised towards the AY14-HMG, consequently requiring both of the triggers’ depressing method operation to allow for the first shot initiation. However, automatic firing operation will be sustained throughout the rest of the gun’s utilisation with only a single trigger, which will henceforward allow for a better energy saving of manpower, whilst simultaneously drastically increasing the gun’s safeties level.

All in all, the AY1A TCR autocannon and its AY14-HMG vehicular counterpart has provided for an ergonomically compact and lethal primary light anti personnel measure and protection towards the AY151B Infantry Fighting Vehicle.

Additional armaments

Additional countermeasure means of the AY151B are the presence of its eight aerosol-smoke fragmentary grenade launchers, with two boxed holding four of the aforementioned launchers on both the left and right side of the vehicle.

The eight smoke-firing and laser detection countermeasure aerosol capable general purpose grenades' conceptualisation was a result of the VMK Bureau's additional requirement of an additional armaments allocation and all-around camouflage protection intensive battle systems to further reinforce its corresponding armoured fighting vehicle's safetiness within its field of engagement, in this case being that of the AY151B.

It utilise the Anago-Yohannesian procurement of an invisible-purposed, fast burning and slow burning charged smoke shell to cover the vehicle's presence from hostile fire when deemed as needed necessarily. As do of most existing smoke grenade's usage, the associated armoured fighting vehicle will then be protected by a partial smoke screen envelopment in-between the associated vehicle itself, and that of the opposing entity's line of fire.

By utilising the rapid establishment of the surrounding thick wall of smoke layers, vehicle's crews would be able to establish a fairly effective means of secondary prevention and camouflage method against the enemy's general abilities to project any of its available power projectile threats against the vehicle, and to further maintain the smoke layers' length of time considerably in durational terms.

The process was done by utilising two smoke emitting, partial charging, differing reactionary and emitting rate, smoke shells. The VMK Bureau of Procurement and Development discovered that the condition in which a longer duration of length the discharged smoke would engulfed and therefore, screened its corresponding armoured fighting vehicle, would be achieved by expelling whilst burst charging the aforementioned smoke shell simultaneously. The result is an approximate slow burning time of 200 seconds after firing.

LA-420A1 Havik II Box launched ATGM fired from an AY2-251.

An optional secondary countermeasure is the utilisation of the internationally renowned LA-420A1 Havik II ATGM, utilised in the form of two box-launched anti tank guided missiles on the surrounding left and right side of its turret, with each box holding four LA-420A1 Havik II, for a total of eight.

With the need for a tank launched anti tank guided missile becoming apparent to LAIX Arms, it was decided to use the Joint Common Missile's body as the basis of the Havik; as it was called, due to the simple design of the missile. Where the original JCM was designed to be launched from helicopters and aircraft; the Havik would be launched from main battle tanks first, with later possible modification to allow it be launched from helicopters and aircraft.

After competing with the Helios II ATGM for supremacy in the international market, the Havik had done relatively well for itself; being considered a commercial success by LAIX Arms. Still, the missile had the potential to become even greater, and it had also only been regarded as more of a stop-gap measure before a newer, better missile would take it's place. This improved missile would become the LA-420A1 Havik II.

The Havik II retains many features that made the Havik such a success, including the general dimensions, while introducing some new features that will help the Havik II compete well into the future.

Guidance for the Havik II is provided by a tri-seeker warhead, combining MMW, IIR, and SALH homing. This is combined with an INS/GPS system, allowing the missile to attain a hit ratio of 95%. In areas where enemy ECM is encountered, the system can also use a fiber-optic connection to the launching mechanism (available in both air and box launched versions). This connection to the launching mechanism is impossible to jam, and will allow the missile to strike the target, with enemy ECM becoming effectively useless.

The Havik II is a top-attack missile, allowing it to strike the weakest part of enemy armour formations. The Havik II is meant to attack opposing armoured fighting vehicles, main battle tanks, and low flying helicopters. However, the missile will simply fly directly toward enemy helicopters when fired in anti-helicopter mode. This helps to increase accuracy against helicopter targets. With a penetration rating of 1,400 mm IRHAe, it will severely damage enemy armour, likely resulting in a kill.

With a maximum range of 18 km (ground launched), and 28 km (air launched), the Havik II can not only be fired from a longer distance than the Helios II, but can also be fired without revealing the location of the firing unit to the enemy. All that the missile needs is the location of the enemy (provided that the enemy units are within range), and it's good to go. The Havik II can also re-attack a target, in case it were to miss, provided that there is enough range left in the missile to allow this. The top speed of Mach 2 was designed to give the enemy little to no time to react, as well as increasing the probability of a kill.

The Havik II retains an active radar jammer, allowing it to bypass the MMW and radar frequencies commonly used in Active Protection Systems. While the Havik used a jammer from Krupp Industries in The Peoples Freedom, the Havik II uses a domestic model, which is smaller, while giving the same performance as the model from Krupp Industries. In addition, the electronics in the Havik II use Gallium Arsenide in place of Silicone, allowing the missiles to survive EMP in good working order. The use of Gallium Arsenide makes the missile more expensive, but the resistance to EMP was judged to be worth the extra cost.

- Length: 2 m

- Diameter: 178 mm

- Weight: 65 kg

- Warhead: Tandem, EFP/Shaped Charge

- Warhead Weight/composition: 20 kg, PBXN 103

- Range: 18 km

- Speed: Mach 2

- Detonation Mechanism: Laser Fuse

- Engine: Solid Fuel, "Low Smoke" Ammonium perchlorate composite propellant ramjet; with launch booster

- Wingspan: 325 mm

- Guidance: 94 GHz Millimeter wave active radar homing, imaging infrared, and semi-active laser seeker, with INS/GPS. Fiber-optics-capable to intercept opposing ECM

- Targets: armoured fighting vehicles, main battle tanks (or any other opposing tanks), low flying helicopters

- Launch systems: main battle tank box launch

- Penetration: ~1,400 mm IRHAe

Where the original Havik was only able to be fired from box launchers mounted on the side of the host MBT's turret, the Havik II can be fired via several different methods. These include:

- Fixed Wing Aircraft

- Helicopters

- Box launchers (AFVs and MBTs)

The Havik II is considered to be too heavy for man-portable use, owing to it's total weight of 65 kg. However, the Havik II can still replace multiple missiles with one proven missile system, saving time and money.

The first stage of the tandem warhead creates an Explosively Formed Penetrator. This EFP moves at high speed, and is able to trigger any Explosive Reactive Armour that the target might have. The secondary shaped charge is where the bulk of the armour penetration occurs, and gives the Havik II it's penetration rating of 1,400 mm of IRHAe. A laser fuse tells the weapon when to detonate.

The Havik II is powered by a ramjet, allowing the missile a maximum speed of Mach 2. The ramjet's fuel contains 78% Ammonium Perchlorate, 20% Hydroxyl-terminated polybutadiene, and 2% Aluminium. This is a "low-smoke" mixture, making it harder for the enemy to trace the firing location of the Havik II via the smoke trail, and does not degrade ramjet performance. At launch, the Havik II is propelled by a low smoke APCP-fuelled launch booster, bringing the missile to speed, thus allowing the ramjet to take over for the rest of the flight.

Taken in combination, these features allow the Havik II to outperform the Helios II, and its spectacular ability to easily destroy opposing armoured fighting vehicles at a range of up to eighteen kilometres has drastically increase and maximise the lethality of the AY151B.

Networking and Fire Control

As in the case of commonality most associated with the Anago-Yohannesian Imperial & Royal Army, the AY151B utilised the advanced AYTRACK battle networking and fire control systems.

AYTRACK as its associated networking and sensory system was conceptualised and developed by the VMK Bureau of Development and Technological Research Committee to provide state-of-the-art Anago-Yohannesian armoured fighting vehicle with the ability to engage hostile mobile targets on the move flawlessly, and thereby increasing its power projectile accuracy and capacity's scope of operational effectiveness and capability within the immediate field of tactical surrounding.

At the most basic level, AYTRACK features electro-optical techniques and electronics which enable the vehicle's gunner to considerably increase the gun's first-strike hit capability in terms of its probability, by measuring automatic error input and replace the value with a post-entered correctional azimuth and elevation signals. These factors will then be recorded into the computer to calculate elevation and lateral co-ordinate position of the gun, which will then automatically invalidate the previously programmed value, drastically increasing the gunner's first hit probability upon the target.

AYTRACK incorporate a two-axis integral laser range-finder line of stabilised gunner sight, together with a missile guidance information processing capacity and a compensatory automatic drift device. Its gun sight features the application of an Anago-Yohannesian XD1-04 computerised controlled targeting mark, or more specifically a range marking, graticule-calibrated application within its sub-systems, with the capability to point its associated gun's specific form of ammunitions, in conjunction to the axis of the corresponding armoured fighting vehicle's gun barrel specification.

AYTRACK's enhanced computer system effectively arrange and provide the appropriate range of ballistic effectiveness value to further provide the AYTRACK corresponding armoured fighting vehicle's crews with the ability to calculate the right specification of the corresponding gun elevation exaction, which would be most effectively be initiated upon by the appropriate circumstance's choice of ammunition range involved regarding the differing situation within the immediate field of operational range.

As a result, crews of the AY151B will be able to initiate pre-programming of the computer to change the exact type of ammunition needed for the right circumstance, and pending the relatively correct input given in regard to the condition only however, in which the parameter of the gun's atmosphere and barrel are at the right set value, the AYTRACK will then be able to automatically provide an accurate target hit value in exaction.

The fire control system's field of view consists of a kinetic energy stadiametric ranging scale, fragmentary high explosive and chemical energy ammunition information and statistics input, designated as it was as an effective Anago-Yohannesian secondary range finding method in case of an unexpected emergency. The system unable the gunner of its corresponding armoured fighting vehicle to accurately and smoothly track and verified its target within its scope of operational range tactically. Further aiding AYTRACK is the X1A-AY GPS sub-system.

Field testing computerised simulation of the initial line of sight.

The Anago-Yohannesian X1A-AY GPS (global positioning system) system of navigation is included to calculate and determine the armoured fighting vehicle's gun barrel position, and it collected its informational input and surrounding visible surface and statistical data within a state-of-the-art light modulating LCD (liquid crystal display) screen.

The X1A-AY is able to give the AYTRACK's corresponding armoured fighting vehicle the ability to observe its immediate surrounding operational condition tactically, and to present a rough and general outline of the vehicle's environmental and physical surrounding. Vehicular radio data furthermore link the corresponding vehicle to the AYTRACK immediate fire control command, which will allow the aforementioned vehicle to initiate its operation upon independent fire-strike missions rapidly once the system has delivered the collected position data of the target. The X1A-AY GPS sub-system further serve to reduce the chance of friendly formational casualties by utilising an Anago-Yohannesian X10-A BCIS (battlefield combat identification system).

Once the target within the input of the main AYTRACK screen is located within an ideal, if not suitable range of interception, the gunner will then be able to fire the gun by pressing a launch section located within the computerised LCD screen.

The development of the AYTRACK fire control system has considerably altered the main disadvantage of the previous heavier AY1 'Serenity''s initial prototype model upon production, which utilised a more basic fire control computing programme, and AYTRACK further enhanced the effectiveness of the AY151B.

The gun sight of the AYTRACK fire control system is also locked in conjunction with its telescopic axis sight, providing a parallel combined gun system, with one set of azimuthally drives and set of elevation, and another set of azimuthally sensors and elevation rate, assisted by the utilisation of a gyroscope gun stabilisation system which further enhanced the associated system's elevation and lateral sensor capability, and in finality, considerably altered the capability of the system to control its corresponding armoured fighting vehicle's gun line of sight.

The AYTRACK fire control system features a gunner's operated thermal imaging sight as well as a commander's active control and monitor panel, allowing both of the commander and gunner to retroactively detect, engage, and verified targets at long range, with a high rate of accuracy, and under some of the most unfavourable weather conditions within the battlefield and tactical scope of operation.

AYTRACK is also divided by two stages in which the commander can select either a low-resolution imagery to identify minor threat, to be followed if necessary by an infra-red, high resolution and radar integrated imagery to provide a more thorough analysis of the target's position, and range. An AYTRACK sub-system commander-operated anti-aircraft sight allows the commander of the AY151B to subsequently engage air targets by utilising a RWS controlled AY02-MG from within the vehicle.

AYTRACK's internally operated target acquisition networking and management systems, infrared and laser ranging controlled data are initiated by controlling its stabilised networking, gunner-operated device to automatically aim the AY151B's main gun towards any visible mobile and stationary target, with a twenty four hour day and night capability coverage, providing an accurate ballistic elevation and azimuth offset field position whilst providing a systematic informational gathering input essential upon the accuracy and capability of an effective modern fire control system.

By utilising the features of a combined sensors sight, in conjunction with its application internally within the AYTRACK computerised fire control system, the AY151B has acquired the ability to effectively countermeasure the ever-growing air threats coming from opposing enemy air support aircraft and ground projectile threat, in finality targeting the aforementioned threat from within its combined sensors sight, and thereby to aim its power projectile capability against the aforementioned threat.

Utilising the latest AYD0B active ballistic computer, the system features the ability to automatically verified angular crosswind and target speed input, course angle, and target range. AYD0B ABC act as a mean of informational input firing statistics data storing within the AYTRACK, and is mainly processed to approximately determine and track ballistic informational data, in-between that of the already stored information and the main collectible data.

The flexibility of the AYD0B active computer system enable the AY151B's personnel to manually utilise the system's ability to track the associated ambient air temperature and barrel wear air pressure, and the ability to calculate with accuracy the necessary time that high-explosive, fragmentary projectile controlled detonation should be initiated over an identified and verified target.

The AYD0B computerised system detected multiple ballistic ammunition and projectile types, and its categorised informational input includes the verified target's drift signals, flight time, and super-elevation. AYD0B computer system operates by utilising a large collection of several sub-channels which will then transmit the collected operational data through several wires simultaneously, and used together in conjunction with an adjustable first operational amplifier which indicate with striking accuracy and precision the information and range of the tracked and verified target.

Armour

The AY151B utilised the standard armour configuration maintained by the AY151 series, with the majority of unneded laters removed as so accordingly befitted towards the role of the armoured personnel carrier, with only important pinpoint and major sections being reinforced by the adversus armour layer.

Adversus is the latest in the LAIX ARMS line-up of armour solutions, originating from the Free Republic of Lamoni. Adversus starts with Exote, which is rated as being effective against small arms armour piercing rounds (including 15 mm armour piercing rounds). The Exote layer is expected to deal with small arms fire and shrapnel from enemy weapons fire. Exote is Titanium Carbide ceramic particles in a metallic matrix. In this case, the metallic matrix is RHA, making it ductile, which greatly improves its multi-hit capabilities while preserving typical ceramic terminal ballistic properties -- high hardness and ablation.

Due to the fact that the ceramic has been suspended in matrix form instead of sintered together, it is cheaper than ceramic tile armour arrays, while providing calculated protection levels equivalent to a 1.77x thickness efficiency, and 2.25x mass efficiency, compared to RHA alone. This process means that Exote is classified as a Metal Matrix Composite, or MMC. Exote-Armour was invented and first manufactured by Exote Ltd., a Finnish corporation.

Upon impact by an armour-piercing round, Exote's Titanium Carbide particles wear down the round via ablation, until the round is effectively turned into dust. Exote also spreads out the energy of the round, and distributes it over a larger area, thus fully neutralizing impact. The damage area is only 20-30% larger than the calibre of the hit, and the rest of the plate will still remain protective. This can be seen in Exote's multi-hit armour characteristic, which provides excellent protection from small arms, with a lighter weight than RHA alone. The Exote is also used to contain the rest of the armour package.

Lamonian innovations in the form of extruded para-organic resilin are also used. Resilin is an elastomeric fibrous compound found within the musculature of insects. To quote Dr Chris Elvin of Australia's Commonwealth Scientific and Industrial Research Organisation;

"Resilin has evolved over hundreds of millions of years in insects into the most efficient elastic protein known..."

Resilin shown under UV at 360nm.

Using genetically modified E.Coli bacteria, the CSIRO team was able to synthetically generate a soluble Resilin protein, based upon the cloning and expression of the first exon of the Drosophila CG15920 gene. By means of a CSIRO-patented process, the resulting resilin rubber was shown to have structurally near-perfect resilience nature, with a ninety-seven percent post-stress recovery.

The next-nearest competitors are synthetic polybutadiene ‘superball’ high resilience rubber (80 per cent) and elastin (90 per cent). The cross-linking process itself is remarkably simple. It needs only three components - the protein, generally lactose, or a near analogue, a metal ligand complex, ruthenium in this case, and an electron acceptor. The mixture is then flashed with visible light of 452 nanometres wavelength to form the polymer - within 20 seconds, the proteins will be cross-linked into a matrix with remarkable tensile strength.

Like it's Acerbitas cousin, the Resilin used in Adversus is intended, as with NERA generally, to warp, bend or bulge the Aermet 100 plates upon impact. As the plates move, bullets are subjected to transverse and shear forces, diminishing their penetration, and shaped-charge weapons find their plasma jets unable to readily focus on a single area of armor. In the case of segmented projectiles, the transverse forces are less pronounced, compared to unitary variants, but the movement of the plate essentially forces the projectile to penetrate twice, again lowering total impact upon the platform protected.

The Resilin components are layered with Aermet 100 plates. The Aermet plates are angled, as penetrators striking angled plates will bend into the direction the plate is facing. This action on the part of the penetrator serves to significantly reduce the impact of the penetrator itself, as the penetrator expends energy on this bending motion, instead of being allowed to focus all of its kinetic energy on a single spot on the armour.

Aermet 100 alloy features high hardness and strength, coupled with high ductility. Aermet 100 alloy is used for applications requiring high strength, high fracture toughness, high resistance to stress corrosion cracking, and fatigue. Aermet 100 is more difficult to machine than other steels; Aermet being specially graded martensitic steel, and requires the use of carbide tools.

Composite Sandwich Panels are used both to increase the structural integrity of the armour, as well as to catch fragments that are created by enemy fire. The outside of the panels are composed of one centimetre thick plates of Aermet 100 alloy. One such plate is placed on either side of the panel. The interior of each panel consists of a three centimetre thick honeycomb of hexagonal celled, thickness oriented Aermet 100, where each cell of the honeycomb measures six millimetres across. Each hexagonal cell is filled with a mix of sintered Titanium Diboride (TiB2) ceramic tiles, and vinylester resin. This adds additional ceramic protection to the armour.

Ti-6Al-4V is a very popular alloy of Titanium. Designed for high tensile strength applications in the 1000 MPa range, the alloy has previously been used for aerospace, marine, power generation and offshore industries applications. Ti-6Al-4V offers all-round performance for a variety of weight reduction applications. It is used to sandwich the Depleted Uranium mesh, encase the SiC ceramic, and as the majority of the armour after that.

As chemically pure Depleted Uranium is very brittle, and is not as strong as alloys, U-3Ti alloy is used for the DU mesh. This alloy has a density of 18.6 grams per cubic centimetre. The alloy displays higher strength, and less brittleness than chemically pure Depleted Uranium.

Silicon Carbide encased in Ti-6Al-4V comes after this, with the Titanium alloy being used to encapsulate the SiC ceramic, as well as assist in hydrostatic prestressing, which is known to extend interface defeat. The SiC is isostatically pressed into the heated matrix; which more securely binds the ceramic into place.

Interface Defeat is a phenomenon observed when a hypervelocity penetrator strikes a sufficiently hard ceramic. The penetrator flattens its nose against the ceramic without penetrating into the ceramic for up to several microseconds, with penetrator material flowing laterally across the face of the ceramic until the ceramic starts to crack. As soon as cracks form, the lateral flow stops and penetration resumes. This effect is also called "dwell" in some publications. Silicon Carbide is excellent for producing this effect.

Most of the armour is concentrated on the frontal arc, with the sides also being covered, but to a lesser degree. The rear of the vehicle is protected by RHA. Where logically applicable.

Active Protection:

As a mainstay of soft-hardkill countermeasure the AYHK10 Active Protection System was designated towards the AY151B.

The AYHK10 ADS defeats and intercepted incoming threats by utilising a hemispherical barrier zone around the corresponding armoured vehicle, in which the utilisation of IR and millimetre wave signals is initiated by targeting hostile missiles or projectiles, which preceded the initiation of screening grenades. These sensors will then deliver its encrypted signals to the corresponding crew within the vehicle. The crucial elements within the AYHK10 active protection system are the ability of its corresponding radars to detect and track incoming threat by utilising an internal soft-kill emitter sensor which will then be automatically processed into the AYHK10 computer system, and its ability to countermeasure and effectively intercept the said threat by inputting the aforementioned process into the AYHK10's sub-systems.

Several sensors which is needed for the corresponding initiation of a full hemispherical coverage, for example that of a collection of flat panel radars which is subsequently placed at strategic locations in the shape of a rectangular zone, with the first and second radars located at the front section of the vehicle, just below the front turret, and the third and fourth located just below the hull of the vehicle, protected by the hauberk armour screening, around the armoured vehicle, are included within the AYHK9's detection and tracking subsystem.

Infrared and millimetre wave detectors are also included and inter-connected into a single transmitter within the system, and are attached outside the vehicle's quadrant points. Each of these has infra-red detection and a millimetre wave tracking system, together with an encrypted early warning transmission device which will then transmit any collected informational input to the vehicle's crew.

The associated receiver of the transmitted informational data will then passed on the information to the commander of the associated formational vehicle, and the commander will then proceed to active the AYHK10-A3 control and tracking sub-system. The aforementioned information will then be processed by the commander's computerised inter-connected sub-system computerised screen, which will then encrypted the aforementioned data, and proceed to either countermeasure the identified threat manually, and/or let the system eliminate it automatically.

Once an incoming threat is detected, identified, and verified, the AYHK9 ADS countermeasure sub-system and device will then be activated and positioned accordingly so as to effectively intercept the verified threat, and the vehicle's designated commander will then be able to activate a systematic button which automatically compute the origination of the threat's direction, and alter the position of the tank's turret towards its direction. It will then be launched automatically into the aforementioned intercepted threat in a ballistic trajectory initiation, consequently providing an adequately long distance of threat interception, within a computerised timeframe of approximately three to four seconds.

Countermeasure submunition initiation of the AYHK10 being conducted within the Valedonia firing range.

Due to the broad hemispherical coverage of its internally built laser threat identifier aforementioned above, the AYHK10 ADS is capable of providing a full three hundred and sixty degree active protection scope of operation to its corresponding armoured fighting vehicle, with its targeted range of projectile within its sensory system to include those of anti-tank guided missiles and grenades, and almost any known and visible target within approximately one hundred metres' surrounding of its corresponding armoured fighting vehicle scope of operation.

In regard to the possibility of a newly emerging projectile incoming target to be identified by the soft-kill emitter sensor, the hard-kill computerised system will then identify and verify the input of the new incoming projectile at a distance of approximately two metres from the system's corresponding armoured fighting vehicle, so as to minimise any unwanted trajectory friendly-fire casualties, all within a reactionary timeframe of just two seconds in-between the old, and the new targeted projectile threat.

The AYHK10 ADS, unlike that of the AYHK9, can also be altered as an effective fast counteractive vehicular protection system, rendering ineffective any hostile rocket propelled grenade initiation in a close range combat situation within a total responsive period of approximately 1.3 ms. A plural passive sensors has been added towards the AYHK10, allowing the active defence system to track and verify its surrounding to locate the threat detected by its laser tracker, which further will determine the angular co-ordination, range, and velocity of the aforementioned threat. Countermunitions will then be initiated, in the circumstance whereas the threat has been regarded as initiated, which will provide a fast countermeasure initiation against its verified hostile target, and its guidance is supported by the AYHK10's computerised software onboard the vehicle.

The AYHK10 ADS is also equipped with its own radiometric countermeasure sub-system, which can be utilised to render invalid any millimetre wave sensory guidance system targeting its associated vehicle, which can be employed by hostile missiles to act as a projector guide towards the vehicle. Dubbed the AYXA-1BS the countermeasure sub-system utilised the existence of a repetitive source of millimetre wave, and an inter-connected system of attenuator and circular light converter to transmit the radiatory millimetre wave signal around the armoured fighting vehicle's immediate surrounding environment.

The aforementioned process will then create a substantial electromagnetic field within the vicinity of the vehicle, which was conceptualised to provide a sufficient radiatory intensity to match the vehicle's surrounding environmental features, such as any surrounding buildings and/or trees within its vicinity. As a result, any sensory detection and radiatory guidance system initiated to assist any hostile missiles towards the AY151B will be rendered invalid and defunct, thereby drastically increasing its survivability rate operationally.

Observability reduction

The AY151B also comes with its own signature reduction system.

Dubbed by the VWK Bureau of Development and Research as the "Lotion", it consists of a multi-spectral light-weight, ultra camouflage net system, based upon the existing ULCANS system.

Lotion consists of two beckets block of loops attached together at the screen of the corresponding camouflaging layer, formed in an alternating conjunction with long beckets block of loops, and to be initiated repeatedly. A detachment of the attached beckets will then automatically dismembered rapidly the aforementioned beckets loops from each other, and thus limiting the existence of a rigid plastic structure within the system, and further decreasing its associated armoured fighting vehicle's chance of detection from hostile infrared radiatory initiation.

A domestically manufactured infrared camouflage screen is used within Lotion, which further decrease the rate of infrared detection of the Lotion's associated armoured fighting vehicle from hostile infrared detection devices and initiation. The layer consists of lightweight pores-contained materials, which will then be attached with strips to its corresponding layer, with the ability to appropriately reducing, depending on the circumstance involved, its corresponding armoured fighting vehicle's infrared detection rate, and is deemed to be effective at a range of over 50 metres from any present infrared and similar means of detection.

Crew amenities

Commonality and Anago-Yohannesian systems tradition has also seen the AY151B's utilisation of the AY09 AFEDSS (AY09 Automatic Fire and Explosion Detection and Suppression System). AY09 AFEDSS is a fully automatic combat operational detection, control, and suppression system, instantaneous and flexibly adjustable to that of a normal and combat mode setting, to be altered as to the circumstances involved within the operational and tactical surrounding of the vehicle.

The primary reason behind the AY09 AFEDSS's development by the VMK Bureau of Design Committee was solely based by virtue upon the AY09's potency to provide a projectile penetration combat protection to Anago-Yohannesian crews and engine on the battlefied by instantly discharging and suppressing fire and/or explosions.

AY09 AFEDSS also features the ability to detect the rise and fall of temperatures within the compartment of the engine by utilising an overheat wire detector, systematically detect and verified a first-degree pressure shock-capable explosion and/or fire within 3.1 ms and suppress it within 100 ms, by utilising its optical fire detection and protection system against HEAT and/or KE (kinetic energy) round penetration, and an operational dual mode automatic status indicator which systematically provide a backing capability in the event of a major malfunctioning of the system.

Furthermore, the vehicle features a central air cooled crew compartment system and a liquid heater based on the engine to accommodate the crew compartment with heating during any possible operations conducted within the period of winter season, which additionally reduce the vehicle's engine heat signature based system. An NBC protected water tank sub-system is also connected to the liquid heater, which can be used for the crew's necessary personal use of cold and/or hot waters in time of need.

The presence of easily-accessible small armaments storage is designated towards the respective crew members' defensive need on the likelihood of any unfavourable scenarios, and a higher rate of survivability was reached by significantly reducing vehicular exposure and pressure shock with the application of AYX47-B1 fibreoptic connections towards the AY151B's electronics.