Nirvash Type TheEND wrote:1890s belt fed LMG lol.

A Lewis Gun style forced cooling shroud, it would work in 1915 or sommat.

Because sometimes even national leaders just want to hang out

https://forum.nationstates.net/

Nirvash Type TheEND wrote:1890s belt fed LMG lol.

Purpelia wrote:Random question time.

As you may remember, I have inquired before about bullets made completely out of steel. And the conclusion we reached is that they would suck because they would be too light for their own good (light = inaccurate) and the lack of a copper jacket means a lack of lubrication in the barrel meaning bad things.

So here is a related question. Say I wanted to make my projectile light for what ever reason. The exact reason does not matter but I do. How would a copper jacketed all steel bullet perform? As in you have a copper jacket and a solid chunk of steel inside without any lead.

United states of brazilian nations wrote:Kouralia wrote:Yeah, sure.

thanks! it will be an important addition to the image for sure.

like this?

..............................................................

well, now proceeding to art the round. i'll need your help, people.

first question of many to come: i'm going to make a ballistic tip round with a plastic tip. now the problem is, i want this particular round to be lead-free. so what should i do?

should i make it steel-cored and copper-jacketed? all-copper? all-brass? or should i use something other than those? if so, what should i use?

i lost track of how many "?" i used in this post

Aqizithiuda wrote:United states of brazilian nations wrote:thanks! it will be an important addition to the image for sure.

like this?

..............................................................

well, now proceeding to art the round. i'll need your help, people.

first question of many to come: i'm going to make a ballistic tip round with a plastic tip. now the problem is, i want this particular round to be lead-free. so what should i do?

should i make it steel-cored and copper-jacketed? all-copper? all-brass? or should i use something other than those? if so, what should i use?

i lost track of how many "?" i used in this post

There's no point in a ballistic tipped round if you're going lead free. Just use a copper jacketed steel projectile (SG=8-8.1)

so, if i were to design a ballistic tip, plastic-tip round, would it be reasonable to use a full copper/brass projectile? would it be affective against relatively unarmored targets (AKA guerrilas)?. then for armored targets, a steel-cored round with an air cavity.

so, if i were to design a ballistic tip, plastic-tip round, would it be reasonable to use a full copper/brass projectile? would it be affective against relatively unarmored targets (AKA guerrilas)?. then for armored targets, a steel-cored round with an air cavity.Imperializt Russia wrote:I was actually looking for a completely different design when I found that.

But it illustrated the point quite nicely.

United states of brazilian nations wrote:Imperializt Russia wrote:I was actually looking for a completely different design when I found that.

But it illustrated the point quite nicely.

i figured that something based around that, with a plastic tip for moar aerodynamics, and made of brass (because copper is fairly more expensive than brass, so much that each one of these in .45 ACP costs around two dollars) would make quite a fearsome round for engaging unarmored targets (because it doesn't look like it's gonna have a lot of penetration).

Aqizithiuda wrote:United states of brazilian nations wrote:

i figured that something based around that, with a plastic tip for moar aerodynamics, and made of brass (because copper is fairly more expensive than brass, so much that each one of these in .45 ACP costs around two dollars) would make quite a fearsome round for engaging unarmored targets (because it doesn't look like it's gonna have a lot of penetration).

Your idea could work, but I believe that brass is harder than copper, so barrel wear will be greater.

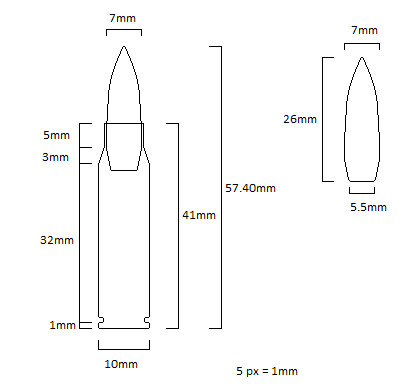

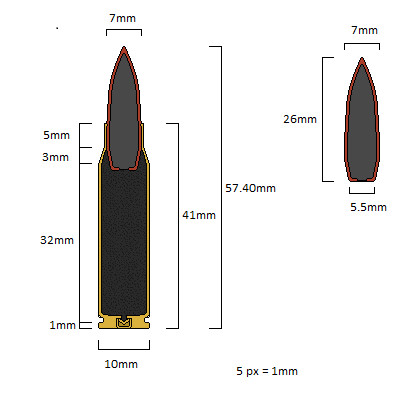

Now, with regards to your round, here's a calculated case capacity for it.

Plugging the case capacity into the Powley Computer, I get 88 kpsi for the velocity you've given. The best I can get with Powley is 2450 ft/s (57kpsi), but LoadAmmo suggests that this will actually be around 60kpsi. 2400 ft/s seems to be about the practical limit for your round.

United states of brazilian nations wrote:Aqizithiuda wrote:

Your idea could work, but I believe that brass is harder than copper, so barrel wear will be greater.

Now, with regards to your round, here's a calculated case capacity for it.

Plugging the case capacity into the Powley Computer, I get 88 kpsi for the velocity you've given. The best I can get with Powley is 2450 ft/s (57kpsi), but LoadAmmo suggests that this will actually be around 60kpsi. 2400 ft/s seems to be about the practical limit for your round.

well, i've made some changes for the round, regarding shoulder lenght and all. mainly so the aesthetics aren't shitty, but it will increase case capacity just a little.

also, i plan on using ticker walls and highly compressed, overpressure charges for moar velocities. specialized AP rounds will be even more overpressure and will probably be steel-cased for that very reason.

in other news, i made an initial drawning:

.

.United states of brazilian nations wrote:Aqizithiuda wrote:

Your idea could work, but I believe that brass is harder than copper, so barrel wear will be greater.

Now, with regards to your round, here's a calculated case capacity for it.

Plugging the case capacity into the Powley Computer, I get 88 kpsi for the velocity you've given. The best I can get with Powley is 2450 ft/s (57kpsi), but LoadAmmo suggests that this will actually be around 60kpsi. 2400 ft/s seems to be about the practical limit for your round.

well, i've made some changes for the round, regarding shoulder lenght and all. mainly so the aesthetics aren't shitty, but it will increase case capacity just a little.

also, i plan on using ticker walls and highly compressed, overpressure charges for moar velocities. specialized AP rounds will be even more overpressure and will probably be steel-cased for that very reason.

in other news, i made an initial drawning:

Bezombia wrote:United states of brazilian nations wrote:

well, i've made some changes for the round, regarding shoulder lenght and all. mainly so the aesthetics aren't shitty, but it will increase case capacity just a little.

also, i plan on using ticker walls and highly compressed, overpressure charges for moar velocities. specialized AP rounds will be even more overpressure and will probably be steel-cased for that very reason.

in other news, i made an initial drawning:

Wait what's the name of this cartridge again?

Aqizithiuda wrote:United states of brazilian nations wrote:

well, i've made some changes for the round, regarding shoulder lenght and all. mainly so the aesthetics aren't shitty, but it will increase case capacity just a little.

also, i plan on using ticker walls and highly compressed, overpressure charges for moar velocities. specialized AP rounds will be even more overpressure and will probably be steel-cased for that very reason.

in other news, i made an initial drawning:

(Image)

If you'll notice, the shoulder I gave the cartridge is the same size as what you changed it to.

Going above 65kpsi is a bad idea for any round, and above 60 kpsi a really bad idea for anything but specialised sniper rounds. Just stick with non-exotic solutions for now.

United states of brazilian nations wrote:Aqizithiuda wrote:

If you'll notice, the shoulder I gave the cartridge is the same size as what you changed it to.

Going above 65kpsi is a bad idea for any round, and above 60 kpsi a really bad idea for anything but specialised sniper rounds. Just stick with non-exotic solutions for now.

well, shit.

but then, how can the 6.8 SPC (which is pretty similar, being only 0.7mm wider at the base and other minor differences i suppose) push a 115 grain round at 2575 ft/s?

also, it appears that the powley computer underestimates loads/pressures/velocities when you get to relatively high pressures (near and/or above 50000 CUP, though i have no idea what would that be in psi).

United states of brazilian nations wrote:well, guess i'll need to make something else then.

http://www.geoffrey-kolbe.com/cgi-bin/t ... age=794366

this has got to be the intermediate cartridge with the worst muzzle velocity ever.

(Image)