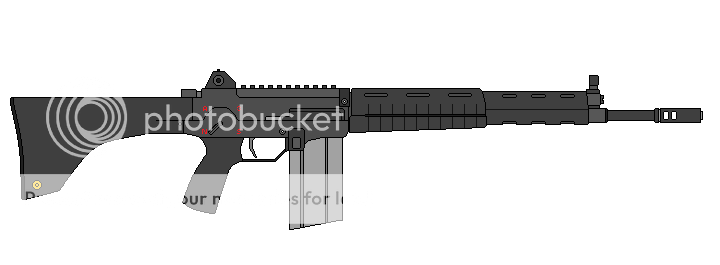

5.56mm AR5R1 Rifle with 20 round magazine, no attachments

5.56mm AR5R1 Rifle with 20 round magazine, Mlyr. 01 Bayonet

AR5R1 Para with folding stock, 30 round magazine

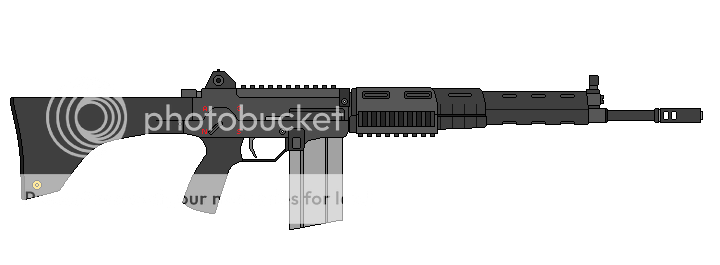

AR5R1 RIS with railed fore-end attachment over outer handguard, 20 round magazine

AR5R1 RIS with red-dot sight, foregrip, laser aiming module, tactical flashlight and 30 round magazine

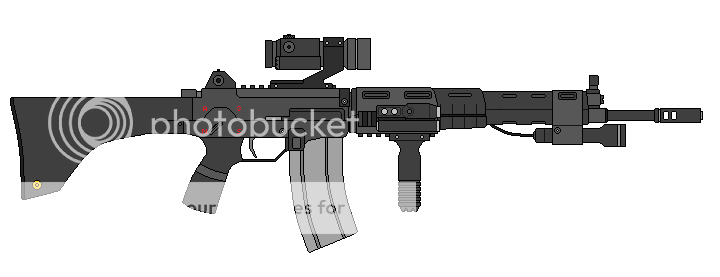

AR5R1 RIS2 with ICO-M sight, foregrip, laser aiming module and 30 round magazine

AR5R1/mod Car with 20 round magazine

AR5R1/mod Car2 with telescoping stock, railed handguard, 30 round magazine

AR5R1/mod Car2 with red dot sight, foregrip, laser aiming module, 30 round magazine

Designer: IFAM/Arsenal Deimos

Designed: 2000

Manufacturer : IFAM

Unit cost: 1260 NSD

Produced: 2000-2008

Common Variants: AR5R1, AR5R1 RIS, AR5R1 Para, AR5R1/mod Car, AR5R1/mod Car2

(statistics are for AR5R1 rifle.)

Weight: 3.8 kg

Length: 1000mm

Barrel length: 523 mm (20.59 in)

Cartridge: 5.56x45mm Arsenal Standard Anemonian

Action: Gas-operated (short-stroke gas piston), rotating bolt

Rate of Fire: 775 rpm

Muzzle velocity: 962 m/s (3,156 ft/s)

Effective range: 580 m (1,903 ft)

Feed system: 20 or 30 round detachable box magazine.

Sights: Rear receiver fixed diopter sight (with flip-convertible small and large diameter sights) and front hooded post.

Background and History

Adopted in 1994, the FAMAS rifle marked the end of the service battle rifle in Anemonian service, ending a tradition that had been begun in 1917. A 5.56mm combat rifle, it was the antithesis of the AR3 rifle; though it packed less of a punch, it did so in a highly compact, light body, and its ability to lay down accurate automatic fire, together with its relative compactness, made it a highly popular weapon amongst Anemonian troops. Fighting with distinction through the opening stages of the Asakuran insurgency, and proving to be a highly effective weapon at close quarters, the FAMAS, or AR4 in Anemonian service, became a tried and trusted infantry weapon within months. It was, in most senses, the perfect rifle for its time, and its one failing was ultimately that which led to its almost universal replacement across the Anemonian Armed Forces; the fact that it was not an indigenously designed rifle.

In 1997, as part of the planning for the introduction of a second Armed Forces Revitalisation Scheme in 2000, the Holy Office of War issued a Request for Information concerning the production of an indigenous 5.56mm rifle that would take the qualities of the FAMAS into account while reintroducing the marksmanship inherent in the design of the AR3R1 to the Anemonian infantry mentality. Many major designers, including Arsenal Deimos (who would go on to develop their entry into the AR6 rifle in 6.5mm Grendel) attempted to seize what was the first big post-1970 indigenous small arms contract; eventually, however, it was the recently restructured IFAM who would go on to win the bid ahead of their competitors in Arsenal Deimos. Developing an unusually large 5.56mm rifle, while keeping its weight down through the use of progressive materials such as fibreglass and aluminium in unprecedented quantities. First producing the AR5 in 1999, following the finalisation of its design at the later stages of the previous year, the design produced by IFAM entered production in January 2000 without any further testing, being distributed to combat personnel in the following month alongside the new, standardised aluminium magazines adopted by the Armed Forces in place of the FAMAS-specific 25 round magazines previously used.

It was a mistake the Anemonian Holy Office of War would learn never to make again. First employed in Asakura, the first production models of the AR5 were arguably the worst designed weapons ever to come out of the Imperial Foundries. Utilising a direct impingement system first employed by the Anemonians in 1949, in the AR1 experimental 7.7mm assault rifle, the weapon had been produced with no chromium lining on the barrel whatsoever, no cleaning equipment and a system that vented hot gases directly into the weapon's action itself; due to a lack of design know-how concernign the fallibility of direct impingement, it was assumed that the high quality powder used in Arsenal Standard Anemonian rounds would render the weapons wholly unsusceptible to the problems usually encountered by such weapons. For the first few weeks, it seemed as though IFAM's rigid belief in its weapon had been vindicated; however, as reports of complete weapon failure began to roll in from the frontlines, with reserve stocks of FAMAS rifles released to compensate for the complete and utter failure of the AR5, the situation reversed.

By June 2005, the government had relieved the IFAM design team of their duties and enlisted Arsenal Deimos in order to provide a low-cost solution to the problem at hand. Thanks to the fact that barely 4000 AR5 rifles had made it off the production lines, IFAM was able to recall these with minimal difficulty; it is said that these were, without exception, destroyed in an act of shame under the direct orders of IFAM's executives. Arsenal Deimos's solution was simple; rather than re-designing the direct impingement system, they wholly converted the AR5's internals into a short-stroke gas piston system, the first instance where this was utilised in an Anemonian service rifle. The good firing qualities of the weapon, together with the marked increase in reliability, was enough to convince the now-wary Crown Army that a solution had been found; by November, the new rifle had entered production in quantity, issued to frontline units in December for familiarisation and utilisation the following month.

It was a success. Impressed by the conventional layout of the AR5R1 and thus its increase in balance, together with the low recoil of the new weapon, Anemonian troops quickly took to the AR5. Though formations like the Marine Paratroopers retained the compact FAMAS for close quarters combat, the vast majority of the Armed Forces made the switch to the new weapon, which proved highly effective in taking over the role of its predecessor across the Armed Forces. Nicknamed 'Second Time Lucky' in a very direct jab at IFAM, the AR5R1 was a well loved rifle, and its replacement in 2008 was a result of the round it fired; the basic design of the AR5 was considered sound enough to warrant its continued usage for years, and resistance within the Armed Forces when its replacement was announced highlighted its remarkably successful operational tenure. Produced in many configurations, ranging from the rudimentary railed-forend attached to the AR5R1 RIS, or the folding stock AR5R1 Para, to the special operations oriented AR5R1/mod CAR2, it has since been completely replaced in Anemonian service by the AR8R5 and AR9, both firing the modern 6.7mm ASA round; however, still utilised as the special operations rifle of the Asakuran Armed Forces, the AR5R1 continues to act as a representative of Anemonian design prowess abroad, salvaged from the graveyard of unreliability to become a sound and stable rifle that served its users well for 8 years, and continues to do so for others.

Design

The AR5R1 is a military service rifle chambered in the ubiquitous 5.56x45mm ASA round. Designed to allow utilisation in a wide range of environments, thus making full use of the 5.56mm round's full range of potential uses, it is a rifle purposely procured to offer Anemonian troops an Anemonian rifle for the then modern battlefield, promoting both marksmanship and close quarters combat by providing a stable and flexible base for the 5.56mm NATO round. Due to the AR3R1 being the last major service rifle built by the Anemonians, it was frequently compared against it during the design process in order to highlight improvements.

One of the key reasons for the AR5R1's remarkable lightness is the fact that it utilises no more than two key materials in its construction; fibreglass and aluminium. The weapon's stock, receiver and handguard, as well as other, smaller components, are built out of 20% glass reinforced polymers. These polymers, used for the first time in Anemonian weapons design, allowed the designers to utilise less materials to achieve similar, if not superior, tensile and compressive strength to the pure polymers used in the AR3/R1 line of rifles. In this manner, they were able to greatly decrease the amount of materials used in the construction of the AR5R1 while retaining the solidity famed in the AR3 line of rifles; the durability of the AR5R1 was a key reason for its battlefield success, this fibreglass allowing it to weather long service periods without replacement of parts, and also greatly increased its resistance to sudden shocks and application of force, greatly enhancing its battlefield utility by making it a highly independent weapons system. Much of the weapon's internals, as well as its inner handguard, are constructed out of aluminium; this 'space age' material, though utilised in some quantity in the AR3R1, was always used in bulk to provide weight to the rifle; with the AR5R1, the decreased recoil impulses of the weaker, smaller 5.56mm round allowed them to sacrifice some of this 'bulk ', while also compensating for some weight loss through a highly effective allocation of weight and an adjustable weight system built into the outer handguard and the fixed stock (if used) to allow individual soldiers to adjust the weapon's weight balance if so desired, without losing the AR5R1's ability to lay down, aimed, accurate automatic fire on the enemy. The aluminium inner handguard is also used to aid heat dissipation; the open metal construction of the weapon quickly transfers heat from the internals to the outside air, greatly assisting heat loss; this, together with the redirection of heated gases inherent in the short-stroke piston action, almost entirely removed the fouling issues relating to heat found so often in the original AR5 rifle; thus, this 'inside, outside' hanguard layout provided a quick solution to the dissipation of heat, thus allowing infantry to use it in high-intensity combat while making full use of its automatic firing capabilities. The barrel is, unlike the rifle's externals, constructed of cold hammer forged steel. It is also, very importantly, internally chromed, thus keeping the possibility of fouling in the barrel far lower than the AR5 rifle. Deconstruction of the rifle has been made relatively simple; first requiring the user to remove the front sighting post, they then detach the outer handguard by means of two screws on top of and under it, whereupon the outer handguard is slid off the front of the rifle. From there, the inner handguard can be unscrewed into two seperate pieces, revealing the barrel and gas assembly. The receiver can also be pulled open; the catch between the handguard and the receive muset be undone to reveal two screws, and two more must be undone at the back of the receiver assembly, allowing the user to pull off the top of the receiver and access the internal receiver assembly (so built to prevent the elements from entering the weapon via the external receiver).

One of the key features incorporated in the AR5R1 rifle is the short-stroke gas piston, introduced as the core of Arsenal Deimos's redesign with the sole objective of removing the reliability issues of the original rifle. The short stroke piston consists of a piston assembly located in a tube above the rifle's barrel, into which the gases and pressure created by the ignition of the cartridge enter through an intermediary vent. The piston is pushed back, thus cycling the action; unlike some short-stroke gas piston systems, the AR5R1 opts not to utilise a connecting assembly to transfer the energy from the piston to the action, instead choosing to do so directly; this is due to the fact that the power of the 5.56mm round is not sufficient to generate recoil impulses and thus an energy transfer capable of damaging the weapon's internals through sustained fire. This short-stroke gas piston directly addresses the key issues of the direct impingement system of the AR5; the reliability and service life of the AR5R1 are greatly increased by the lack of vented gases and accumulated heat, while the lower mass of recoiling parts found in the short-stroke system as opposed to other recoil-operated rifle actions means that it remains a highly controllable rifle, even in sustained fire; thus, the AR5R1 manages to make the most of the 5.56mm round's qualities while introducing unprecedented reliability to the AR5 platform. The ejection system utilised in the AR5R1 rifle is a simple, rightwards spent casing system; provision for left-sided ejection is only provided with the installation of a new receiver assembly. The charging handle is located behind the receiver in an AR-15 style manner; by removing the charging handle from the handguard assembly, the AR5 greatly simplified the disassembly process, while putting it on the receiver would have forced the designers to further complicate the receiver's disassembly by making the removal of the upper receiver in the manner in which it is an impossibility. It is an orthodox design, and one optimised for practical applications. The flash hider on the AR5R1 is vented to direct gases in a manner that dispels most force equally, with a particular focus on counter-recoil to compensate for the rifle foreend's relative lack of weight in comparison to the rest of the weapon, as was the case with the AR3R1 rifle.

One of the key elements of the AR5's design is the utilisation of a STANAG-4179 compliant magazine and magazine feed in a departure from the FAMAS's unorthodox and unstandardised 5.56x45mm feed. Though under no external pressure to do so, the adoption of generally standardised feed dimensions by multiple overseas weapons developers and manufacturers had been noticed in more recent years; in an effort to emulate this, and thus allow for ammunition interchangeability between other, similar 5.56mm rifles, IFAM designed the magazine feed of the AR5 rifle to follow these standardised dimensions and did likewise with the feed device, adapting the 25 round aluminium box magazine of the FAMAS rifle to create a new feed device. The original AR5 was equipped with a 20 round magazine as part of a General Staff initiative to cut back on ammunition waste by encouraging infantry to conserve ammunition; this 20 round magazine, though utilised after the adoption of the AR5R1 in some cases, was complemented and mostly supplemented by Arsenal Deimos's own 30 round aluminium box magazine which, through its pioneering of a fibreglass follower and spring steel, was able to cut back on the size of the follower and spring device, thus decreasing the space taken up by these assemblies in the magazine and greatly increasing their efficiency, pound for pound. The self-lubrication of this new follower greatly increased the reliability of the box magazine; though the materials used to create the exteriors of box magazines have changed since then, the internal construction pioneered by the AR5R1's 30 round STANAG compliant magazine is still used today in the polymer magazines of rifles like the AR8 or AR9. Across certain areas of the armed forces, higher capacity magazines such as 80, or even 160, round drum magazines have been said to have been manufactured and issued by Arsenal Deimos; however, very few of these magazines will have been issued, and most likely not in an official capacity.

Sights on the AR5R1 were originally envisaged to be the primary and solitary sighting method of the infantryman, as was the case with the AR3R1 and FAMAS in Anemonian service before it; as a result, though the integration of infantry optics eventually resulted in the increasingly frequent usage of externally mounted powered sighting equipment over ironsights, the AR5R1's ironsights were not only built to work, but to work well and last. The AR5R1's ironsights are based around a circular enclosed rear diopter and a hooded front post with a three-pronged sighting profile. This simple, tried and tested target acquisition system are effective out to about 300 to 400 metres for point shooting; however, these wide diameter rear diopters are so designed to allow for rapid target acquisition and elimination rather than accurate shooting; one of the most important features of the AR5R1's ironsights are the flip up rear diopters, which allow the shooter to access and utilise a smaller diameter, narrower and thus more accurate rear diopter by pushing forward the general use sights forwards for accurate point fire out to, in some exceptional cases, over 650m metres, allowing the shooter to fully utilise the AR5R1's long barrel while engaging the enemy at longer distances. The sights are fully windage adjustable through a pair of rotating knobs on the rear sighting assembly and screws on the forward sights. These different levels of eye relief, together with the accurate windage adjustment, give the AR5R1's ironsights a level of flexibility and precision that underline its role as a general issue and use sighting system rather than a backup.

Ergonomics are another, key feature of the AR5R1's design. Developed to replace the bullpup and highly favoured FAMAS, it's ultimate objective was no easy one; to reintroduce a standard layout rifle which an average infantryman would be more comfortable with than a compact and highly usable bullpup weapon; in this respect, it was a great challenge. The grip was essentially that of the AR3R1 rifle; the polymer construction of the pistol grip increased the 'grip' of the part, especially due to its designed texturing; this gave the AR5R1 a propensity to 'stick' in the infantryman's hands in a manner in which the FAMAS could not, especially during high intensity combat; where perspiration would normally decrease the friction between hand and grip on a rifle like the FAMAS to the extent that it could slip out during a crucial moment, the large, textured pistol grip of the AR5R1 retains its grip on many surfaces, ranging from human skin to rubber gloves, giving it an edge over the FAMAS in high intensity combat despite its apparent bulkiness. The trigger guard is expanded to permit use of a glove-wearing index-finger if necessary; the trigger itself is curved to match the shape of the firing finger, greatly decreasing the shooter's potential to 'finger' the weapon (that is to say, apply excessive force while pulling the trigger and thus decreasing accuracy greatly by pulling the rifle's point of aim off target before firing the weapon) by allowing the shooter to pull the trigger in a fluid motion rather than force it back; the relatively low trigger pull contributes greatly to this. The entire firing hand assembly is built to keep the hand at a slight forward angle, together with a curve for the thumb just underneath the receiver; in this manner, wrist fatigue is avoided in every firing position. The fire selector of the weapon follows a highly unorthodox four-pattern system; the two immediate accesible options available to the soldier, automatic and semi-automatic, allow them to respond quickly to the immediate necessities of the battle, but a three round burst option is also included within the selector layout in the event that infantrymen wish to conserve ammunition while laying down sufficient volumes of fire in high-intensity, high-pressure extended combat periods where controlled automatic fire is difficult to achieve. The selector switch itself can be set to either automatic and semi-automatic with the thumb, and is ridged horizontally to facilitate control; the index finger of the firing hand, meanwhile, can be used to set it to a three round burst, one reason for the ambidextrous placing of the selector assembly (the second being that the selector switch acts as another screw for the internal receiver as well). The magazine eject is also placed in front of the trigger assembly for access by the index finger, and is placed in a recessed alcove to facilitate its operation. The charging handle is the only aspect of the weapon that forces the infantryman to break their firing position to permit operation; this, though an unfortunate ergonomic flaw of the rifle, was perceived as necessary to simplify the disassembly and construction process of the rifle; it is also incidentally ambidextrous, an advantage for those left handed shooters capable of firing while disregarding the casings being ejected in their direction. The handguard assembly of the rifle is a particularly unique aspect of its ergonomic design. The outer fibreglass handguard is both textured and shaped to maximise grip and comfortability during extended shooting periods. The inclusion of a dual tiered handguard is also useful in that it slightly decreases the weight of the rifle by removing the need for a forward fibreglass portion to the weapon, essentially only placing a handguard where it is necessary while utilising aluminium where it is not. This decreases the bulk and weight of the forward portion of the weapon; in this way, it also greatly facilitates the movement of the rifle and thus aids in rapid target acquisition, providing the AR5R1 with yet another close quarters boon over its competitors. The rifle stock is the last ergonomically significant component of the weapon; again, constructed of fibreglass, the upper portion of the stock is mildly, almost unnoticeably textured to provide as high a level of comfort as possible with a fibreglass stock while increasing cheek grip, thus increasing the stability of the weapons system through the shooter's own head. The buttstock is rubber to provide both comfort to the shooter's shoulder through an elastic and relatively shock absorbant material; it attempts to provide as much an advantage as possible without overcomplicating the basic design of the component.

Various versions of the AR5R1 were also produced to fulfil a number of different roles. There were very basic modifications; the AR5R1 Para fitted the base rifle with a folding stock equipped with a cheek rest to decrease the size of the weapon for use by paratroopers, while the AR5R1 RIS fitted a three-side rail interface system as an attachment onto the basic upper handguard of the AR5R1 rifle (produced as standard issue from 2003 onwards). Some other, more significant modifications were also made to the rifle; prime amongst these was the AR5R1/mod Car and Car2, carbine modifications made to the base AR5R1 rifle. The base Carbine was simply an AR5R1 rifle featuring a shortened barrel and handguard, with the weapon retracted up to the outer handguard to greatly shorten the size of the weapon. Produced with the same fixed stock as the AR5R1, and with no other modifications, it was employed in much the same capacity as the AR3R1's 'Carabinyr' pattern model in the Anemonian Armed Forces; issued at a division level as per request, it was handed out to infantry participating in long periods of intensive close quarters combat as a shorter, more usable alternative to the longer AR5R1; produced from 2001 to 2003, it was a weapon which saw limited service in Asakura. The Car2 was a more comprehensive modification to the AR5R1 rifle, and was produced on different manufacturing lines to the original Carbine; its two key additions were a telescoping stock with a sloped cheek weld in an ergonomic style coming into favour in 2005, when it was designed, as well as a four-side rail interface system which was attached onto and on top of the AR5R1's outer handguard. This weapon was primarily procured and produced for use with Anemonian Special Operations, who utilised the weapon until the end of production and procurement in 2008, when they shifted over to using the more modular and superior AR8R5 weapons system.

The AR5R1 is a remarkable weapons system; an experiment in 21st century Anemonian weapons design, this attempt to revitalise indigenous small arms developement seemingly ended in failure with the disastrous results of the AR5 rifle in 2000; however, rejuvenated and risen from the ashes after some internal modifications by Arsenal Deimos, it grew to become one of the most solid, dependable and, in areas, innovative weapons systems in Anemonian history, marking the beginning of the Holy Empire's re-entrance into weapon's development with a loud, reliable, usable and highly accurate 'bang'.