Oh hey, I topped the page

Advertisement

![]() by Idaho Conservatives » Wed Apr 03, 2013 8:43 pm

by Idaho Conservatives » Wed Apr 03, 2013 8:43 pm

![]() by Spreewerke » Wed Apr 03, 2013 8:43 pm

by Spreewerke » Wed Apr 03, 2013 8:43 pm

Samozaryadnyastan wrote:Puzikas wrote:

I seen it, with my own two eyes I did!

During training, someone loaded their pistol for the entry. At no fault of their own, the pistol suddenly discharged into the rear of the man in front of him, into his helmet. It was an AP load too! And you know what? That guy had a headache, but managed to beat the shit out of that poor fuck who had the weapon malfunction.

Why was he pointing a loaded and chambered handgun at the guy's helmet?

![]() by The Republic of Lanos » Wed Apr 03, 2013 8:44 pm

by The Republic of Lanos » Wed Apr 03, 2013 8:44 pm

Idaho Conservatives wrote:I wonder: Is the round count in the Mess Webley (4 shots fired so far) accurate?

![]() by Transnapastain » Wed Apr 03, 2013 8:49 pm

by Transnapastain » Wed Apr 03, 2013 8:49 pm

Idaho Conservatives wrote:I wonder: Is the round count in the Mess Webley (4 shots fired so far) accurate?

![]() by The Republic of Lanos » Wed Apr 03, 2013 8:50 pm

by The Republic of Lanos » Wed Apr 03, 2013 8:50 pm

Transnapastain wrote:....its not funny when its not deserved...

![]() by San-Silvacian » Wed Apr 03, 2013 8:56 pm

by San-Silvacian » Wed Apr 03, 2013 8:56 pm

![]() by Idaho Conservatives » Wed Apr 03, 2013 8:56 pm

by Idaho Conservatives » Wed Apr 03, 2013 8:56 pm

![]() by Lolzieristan » Wed Apr 03, 2013 8:58 pm

by Lolzieristan » Wed Apr 03, 2013 8:58 pm

![]() by Ulfr-Reich » Wed Apr 03, 2013 9:02 pm

by Ulfr-Reich » Wed Apr 03, 2013 9:02 pm

San-Silvacian wrote:ASKING QUESTIONS WHEN NOT DESIGNATED TIME OF QUESTIONING IS ILLEGAL.

MESS WEBLEY. NOW.

![]() by Samozaryadnyastan » Wed Apr 03, 2013 9:03 pm

by Samozaryadnyastan » Wed Apr 03, 2013 9:03 pm

Malgrave wrote:You are secretly Vladimir Putin using this forum to promote Russian weapons and tracking down and killing those who oppose you.

![]() by San-Silvacian » Wed Apr 03, 2013 9:07 pm

by San-Silvacian » Wed Apr 03, 2013 9:07 pm

![]() by Nua Corda » Wed Apr 03, 2013 9:07 pm

by Nua Corda » Wed Apr 03, 2013 9:07 pm

![]() by Spirit of Hope » Wed Apr 03, 2013 9:12 pm

by Spirit of Hope » Wed Apr 03, 2013 9:12 pm

Imperializt Russia wrote:Support biblical marriage! One SoH and as many wives and sex slaves as he can afford!

![]() by The Archangel Conglomerate » Wed Apr 03, 2013 9:20 pm

by The Archangel Conglomerate » Wed Apr 03, 2013 9:20 pm

Aqizithiuda wrote:Was there anything in particular that you didn't understand or that I could explain more clearly?

By the way, this might be of interest to you: http://www.dtic.mil/dtic/tr/fulltext/u2/736856.pdf

It basically describes how to coat small caliber gun bores with tungsten for improved wear and resistance to erosion.

Nirvash Type TheEND wrote:For want of lances, the heavy equipment never reached the field.

For want of heavy equipment the platoons FOs could direct no HMGs.

For want of HMGs, the Archians had to rely on shitty fucking microcalibers.

For want of real weapons, they lost the war.

![]() by Black Hand » Wed Apr 03, 2013 9:20 pm

by Black Hand » Wed Apr 03, 2013 9:20 pm

Spreewerke wrote:Oh boy.Black Hand wrote:The greatest advantages of high velocity are accuracy and not just level flight. At higher velocities it becomes easier to adjust for range and movement, the shooter becomes harder to detect (sound Crack-thump) and finally penetrative power a small projectile carrying a lot of velocity has a lot of force concentrated into one very small area with very little air resistance. just one moment, Spree, Puz, I apologize for what I'm about to do. The AKM uses the 7.62X39 The M16 uses 5.56x45 the M16 has a few advantages ammunition wise it has less recoil and more accuracy as well as a greater possibility to tumble this makes the M16 (when it worked) a superior weapon. This was evaluated and studied and later developed into the 5.45X39mm that is now used in the AK-74 the ammunition is smaller, lighter, and faster allowing it to be more accurate with less recoil and have a similar effect while being able to carry more ammo with the same weight. note that this was before body armor was even really an issue (Vietnam flak jacket does not count for more reasons than one) the AP capabilities only became a concern later and frankly when you hit an unarmored target with an bullet the damage is going to be bad... very bad.

M67 7.62x39mm says, "wut?"

M67: increased penetration of 7.62x39mm, tumbling/yaw effect of 5.45x39mm.

Puzikas wrote:You clearly don't know about the baby bald eagle built into each one.

Dumb Ideologies wrote:Why is there a "joke option" included in the poll when "yes" is already there?

Fordorsia wrote:Sight rib? Like a barbecue?

Fordorsia wrote:Why sell the restored weapons when you can keep them in a military-themed sex dungeon?

San-Silvacian wrote:Nothing says I love you like a fine Belgian firearm.

Bezombia wrote: "glorious discharge"

![]() by Ulfr-Reich » Wed Apr 03, 2013 9:44 pm

by Ulfr-Reich » Wed Apr 03, 2013 9:44 pm

![]() by Lyras » Wed Apr 03, 2013 9:47 pm

by Lyras » Wed Apr 03, 2013 9:47 pm

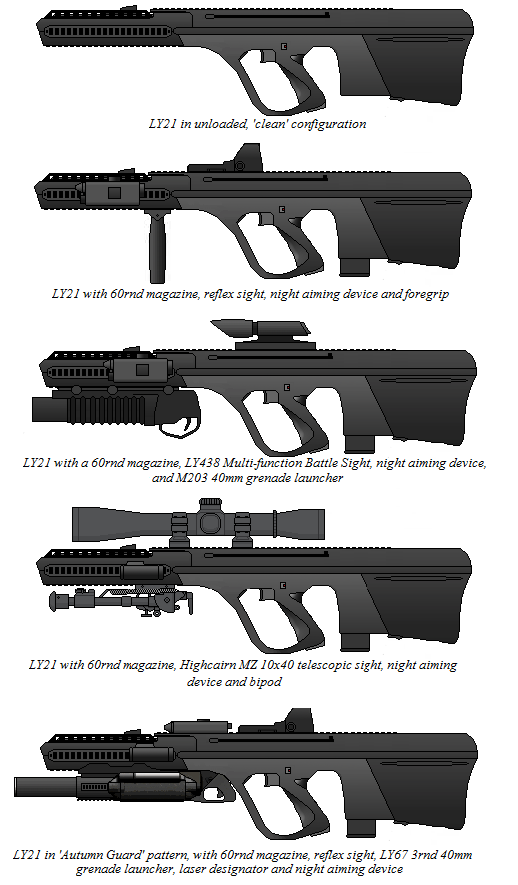

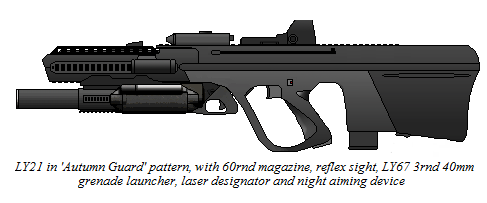

For decades, single shot 40mm grenade launchers like the M203 have been the only realistic way to provide a grenade launching capability mounted on the main personal weapon of the warfighting soldier. The lack of a multi-shot, semi-automatic capability for every soldier severely limits the operational effectiveness of the existing systems, as in the heat of battle a slow, manual reload is often untenable.

Mokastana: Then Lyras happened.

Allanea: Wanting to avoid fighting Lyras' fuck-huge military is also a reasonable IC consideration

TPF: Who is stupid enough to attack a Lyran convoy?

Sumer: Honestly, I'd rather face Doom's military with Doom having a 3-1 advantage over me, than take a 1-1 fight with a well-supplied Lyran tank unit.

Kinsgard: RL Lyras is like a real life video game character.

Ieperithem: Eighty four. Eighty four percent of their terrifyingly massive GDP goes directly into their military. And they actually know how to manage it. It's safe to say there isn't a single nation that could feasibly stand against them if they wanted it to die.

Yikes. Just... Yikes.

![]() by Aqizithiuda » Wed Apr 03, 2013 10:04 pm

by Aqizithiuda » Wed Apr 03, 2013 10:04 pm

The Archangel Conglomerate wrote:Aqizithiuda wrote:Was there anything in particular that you didn't understand or that I could explain more clearly?

By the way, this might be of interest to you: http://www.dtic.mil/dtic/tr/fulltext/u2/736856.pdf

It basically describes how to coat small caliber gun bores with tungsten for improved wear and resistance to erosion.

Not really. The more I read through it, the more it makes sense. It's actually rather simple and well thought out.

I do, however, find out humorous that you, in you're spare time, built a cartridge that would have easily outperformed the GSHG's 4.73x33mm cartridge.

Thank you for the link, I look forward to reading it.

.

.Black Hand wrote:

sorry I have my failures...many, many failures. while I know a reasonable amount regarding ammunition overall I know little about specific variants of the ammunition (note: i persoanlly believe that the 7.62X51 is the best "rifle" round and that the 7.62X39 is the Best intermediate round) The AKM Is a fully capable assault rifle but the the possibility of creating a small round such as a 3mm or smaller that can achieve a velocity in the area of 1700-2700 m/s will be able to rip through armor plate, walls and even vehicles. At these speeds even drop is negligible and compensating for movement is a none issue leaving only air resistance and stabilization as difficulties terrifyingly nothing involving this is impossible with modern technology it merely lacks the necessary attention and funding. the goal of such a weapon is to punch nice neat holes in targets at long ranges this style of weapon is perfect for snipers. however in the modern world urban warfare is much more common and as such weapons like the AKM are far superior as they have the power and accuracy necessary for these ranges without an extreme cost or recoil (to get such a round moving at those speeds would require quite the load)

EDIT: I found room for it in my sig

Nationstatelandsville wrote:I liked the prostitute - never quote me on that.

Puzikas wrote:This is beyond condom on toes. This is full on Bra-on-balls.

Puzikas wrote:Im not cheep-You can quote me on that.

Hellraiser-Army wrote:and clearly I am surrounded by idiots who never looked at a blueprint before...

![]() by Lyras » Wed Apr 03, 2013 10:11 pm

by Lyras » Wed Apr 03, 2013 10:11 pm

Mokastana: Then Lyras happened.

Allanea: Wanting to avoid fighting Lyras' fuck-huge military is also a reasonable IC consideration

TPF: Who is stupid enough to attack a Lyran convoy?

Sumer: Honestly, I'd rather face Doom's military with Doom having a 3-1 advantage over me, than take a 1-1 fight with a well-supplied Lyran tank unit.

Kinsgard: RL Lyras is like a real life video game character.

Ieperithem: Eighty four. Eighty four percent of their terrifyingly massive GDP goes directly into their military. And they actually know how to manage it. It's safe to say there isn't a single nation that could feasibly stand against them if they wanted it to die.

Yikes. Just... Yikes.

![]() by Ulfr-Reich » Wed Apr 03, 2013 10:24 pm

by Ulfr-Reich » Wed Apr 03, 2013 10:24 pm

![]() by Spirit of Hope » Wed Apr 03, 2013 10:30 pm

by Spirit of Hope » Wed Apr 03, 2013 10:30 pm

Lyras wrote:Ah, well, in that case...Lyran LY1002 'Hellsbreath' thermobaric hand grenade

(Image)

Length : 100mm

Diameter : 58mm

Weight : 375g

Filling : 110 grams, YJ-05, ethylene oxide, energetic nanoparticularised-and-floridated aluminium

Fuze delay : Variable. Default 5secs

Shell : Semi-perforated Kraton polyamide-coated aluminium, tungsten pellet inserts.

Casualty radius:

Kill: 6m

Casualty: 12m

Danger: 30m

Abstract

The LY1002 'Hellsbreath' is an in-service, purpose-built thermobaric hand grenade, designed and built by the Lyran Protectorate. It is known in Lyran service as the 'Hellsbreath' or the 'ten-oh-two'.

Background

While there exist a number of more or less similar hand grenades, the world over, the Lyran Protectorate was not satisfied was the same generic weaponry as the rest of the world. In keeping with the ever-present desire to realise full-spectrum overmatch, Executive Command directed the Protectorate Research and Development Commission to design, develop and manufacture a hand grenade that would optimise combat effectiveness for combat infantrymen.

As part of the development process, several seperate and relevant characteristics of grenades in general were identified and isolated:

1.)Short employment range

2.)Small effective/casualty radius

3.)Delay element/fuze

4.)Shell.

Further to that, hand grenades were determined, by nature, to consist of a body, which contains a filler (normally the explosive charge and/or projectiles) and a fuse, which is the means by which the grenade is made to explode by detonation or ignition.

(Image)

The aim of the development was to therefore utilise and modify the constituent parts of the grenade to optimise the lethality of each characteristic, to the total combat utility of the package.

Explosive Filler

Perhaps the most important choice for grenade design is the selection of the filler composition. It is, in many respects, the defining feature of a grenade. The selection of the filler for the LY1002 was, as could then be expected, the longest component of the weapon's design process. Conventional (condensed explosive), Fuel-Air and Thermobaric were the three general forms of filler-charge available, and across that spectrum were a whole host of individual explosive mixtures, making the process of explosive selection therefore a very involved one.

A fact well known since ancient times is that generally shrapnel is the major source of lethality for most warheads, as it has an effective radius far greater than blast. Shrapnel is the staple engine of casualty for most modern hand grenades, for that reason. However shrapnel does have its limitations, chief amongst them the limitations of shrapnel penetration of armoured targets. In this regard, blast becomes more useful.

However, if maximum blast is sought, then fuel-air explosives are usually the most effective, and fuel-air explosives generally do not create shrapnel. A fuel-air explosion has two phases: first the gas or aerosol is released to form a cloud which mixes with the air. In the second phase the cloud is detonated, producing an explosion which is much more powerful than the equivalent condensed explosive. However, unlike a condensed explosive, it is unable to split open a casing and convert it into fast-moving anti-personnel shrapnel. So, as a consequence of that, although fuel-air explosives are extremely effective at destroying buildings, they are considerably less useful against other targets.

Thermobaric explosives lie somewhere between pure fuel-air and condensed explosives. A thermobaric explosive can be solid but 'fuel rich', for example such a mix of regular explosive with powdered aluminum or similar material. When it is set off, the thermobaric explosive produces an expanding fireball, with the leading edge containing white-hot aluminum particles which add to the explosive effect as they come into contact with the air and burn.

The following performance-based criteria for fill selection were established:

1. Good fragment driving properties,

2. Enhanced blast properties

3. Good IM characteristics,

4. Evidence of survivability under penetration loading/setback.

Also relevant were ease of training and qualification, and, lastly, but still a factor, was cost of fill in production and installation terms

.

A number of conclusions relevant to selection of an explosive were considered. Most important was with reference to how a grenade is used. Using a grenade is a conscious act for a soldier. Personnel do not snap-fire a grenade. Grenades are employed deliberately, normally against targets in some form of cover. If they were NOT in cover, generally a rifle or direct fireweapon is employed. Blast and overpressure were thus determined to be higher priorities for neutralising hostile forces in cover than had previously been appreciated, especially when used in hand grenade form, rather than, say, tube artillery.

Designers were, from the outset, not married to any given explosive formula, and experimentation and development continued to determine optimum composition, with categories of interest being listed as:

1)Peak pressure

2)Pressure impulse

3)Temperature

4)Fragment velocity

5)Fragment perforations and

6)Heat flux

One explosive fill came out a clear leader, scoring best not only on the blast pressure and blast impulse but also best on fragment velocity and the number of fragment perforations it produced, way outperforming the existing filler in both categories. The explosive composition that generated (at testing on the 4th July, 2004) the highest peak pressure and pressure impulse (23.33psi and 2.23psi/ms respectively) also generated the highest fragment velocity and highest number of fragment perforations (1580m/s and 564). This was up against a peak pressure, pressure impulse, fragment velocity and fragment perforation of 9.91psi, 1.617psi/ms, 1449m/s and 396 respectively for conventional Composition B. While this particular mixture did not feature the highest temperature or highest heat flux, it still performed well in those categories, very comparable to PBXN-109, another baseline composition.

This mixture, YJ-05, designed by Ensign-Bickford Aerospace & Defense, was selected by the Lyran Protectorate for its LY1002 program, on the basis of these results, and also for the US Military's XM1060 40mm rounds.

In usage, the YJ-05 filler drives both the ethylene oxide, and the energetic nanoparticularised-and-floridated aluminium, which is dispersed and rapidly ignites/combusts/detonates. The resultant sustained high pressure wave is phenomenally effective against enemy personnel and structures. The lethality effect results from a thermobaric overpressure blast rather than fragmentation. As a result of the thermobaric reaction, all enemy personnel within the effective radius will suffer lethal effects as opposed to the conventional fragmentation round, which can be halted by such things as heavy clothing or body armour. Body armour will NOT stop the effects of a thermobaric detonation, and the LY1002 consciously seeks to take advantage of this fact. When taken in toto, the thermobaric explosives provide soldiers with a significantly greater probability of killing or incapacitating hostiles within the weapon's effective radius.

Fuse and pin assembly

An aluminium-framed indium-gallium arsenide electronic fuse is fitted to the LY1002, not only so as to ensure the absolute optimum in reliability and consistency, as well as not adding the fuse assembly to the projectiles, also provides several tactically appropriate fusing options. These include variability from 1 second to 10 seconds in delay fuse, and an impact detonation toggle.

For ease of use these options can be selected using just two tumbler-type controls, one to toggle the impact mode, the other to set the time delay option. The Impact dial has the options Impact, Impact + time, and Off. When pulled straight out of the box, the fuses are set to five second delay, and will remain that way unless adjusted. More than one unit has chosen not to adjust at all, but SF units in particular find the function exceedingly useful.

Shell

The LY1002's shell is not dissimilar to a number of other grenade shells. The exterior coating is ribbed for easy grip, and made of non-slip kraton polyamide. The aluminium of the shell is also designed to fracture and add aluminium particulate debris and mass to the ensuing blast wave.

The LY1003 is a reusable/refillable training model of the -1002, made with a reinforced steel shell and a modified fuze, containing a compound intended to simulate the detonation of the grenade.

Carriage

For carriage of the grenades, the Protectorate Research and Development Commission redesigned grenade pouches. Made of a fairly standard xyalane-treated polyester and cotton weave, the pouches are designed to prevent the lever being released (and thus the grenade fuse activated), even if the pin comes loose, while still allowing easy carriage and rapid access. A variety of differing camouflage patterns for the material are available, and the system features easy and modular adaptation to all sorts of load-bearing systems.

(Image)

(Image)

Export

An LY1002 is available for NS$25, and DPRs to the LY1002 (and LY1003 with it) are on sale (to approved parties) at NS$10bn. Upon purchase of DPRs, or more than 1,000,000 individual items, approval is granted to the purchasing state to produce the Lyran Arms-patented grenade pouches, without restriction. Purchase requests and enquiries can be lodged through Lyran Arms.'Dauntless' Body Armour

Dauntless – Lyran desert camouflage pattern

Dauntless – Lyran snow camouflage pattern

Conceptualisation:

“Dauntless” is the Lyran Protectorate's range of ballistic armors. Designed for all forms of conflict, and to be practical in any situation, “Dauntless” provides a number of alternate solutions that can be selected according to the theatre of operations ranging from the ultra-lightweight class III-equivalent 'Arachne' to the super-resistance medium-weight class IV+ combined armour.

Background and development

Armour, in the abstract, is not new, or even close to it. Ever since man wrapped himself in animal skins to protect himself from someone next to him, there has been armour. As weapon capabilities increased, armour kept pace to match, and the trend continued for thousands of years.

With the advent of firearms, however, altered this situation. Within a relatively short period of time, the mobility cost of wearing heavy armour no longer justified its protective qualities, when pitted against musketry. Armour left the battlefield.

In the 20th century armour made something of a return. From the early days of the first world war, soldiers on both sides of the conflict were issued protective headgear. Helmets were the first element of armour to make its return to the battlefield, primarily with the intention of shielding the head from ricochets and shrapnel. Initial forays into body armour was less successful, with the protection of limited utility, and the weight prohibitive.

Over time, this changed. The advent of synthetic or semi-synthetic compounds that were both light and strong brought down the weight of body armour considerably, and by the last decade of the 20th century, ballistic protection was improving by leaps and bounds. During the aftermath of the second gulf war, coalition forces within Iraq issued body armour to their soldiers as standard, and, since that point, the trend has continued.

As would be predicted, however, the firearms and tactics have adapted to match. Increased use of high-velocity armour-piercing (or frangible) ammunition, explosives and higher-calibre weapons has, in many ways, pushed the balance back the other way. Personnel within many armies are, once more, eschewing the use of body armour as too bulky and restrictive, and thus actually increasing their chance of being hit or killed.

Into this situation, Lyras decided to act. Painfully aware of the enormous expense in time and resources that each Lyran soldier represented, Warmarshal Krell directed the Protectorate Research and Development Commission to research, design and develop a range of ballistic armour that would be practical to use, as unrestrictive as possible, and offer unparalleled protection against existing and predicted threats.

Research was, undoubtedly, the largest, longest and most labour-intensive element of the requirement. While no doubt a rapidly developing and growing field of study, modern ballistic protection was still very much in its early stages of development. Semi-resistant fabrics held heavy, bulky ceramic plates in place over vital areas, and mobility, both through weight and movement restriction, suffered as protection increased. Very quickly, the individual soldier's combat load was becoming very difficult to manage. Dyneema/Kevlar/Spectra-based products were effective, of that there was no doubt, but methods for increasing protective capabilities so as to greatly decrease weight were sought.

Two primary fields emerged as the areas of greatest interest, in 'hard' and 'soft' armour categories respectively. Hard body armour is made out of thick ceramic or metal plates, functions basically the same way as the iron suits worn by medieval knights; it is hard enough that a bullet or other weapon is deflected. That is, the armour material pushes out on the bullet with the same force (or nearly the same force) with which the bullet pushes in, so the armour is not penetrated.

Typically, hard body armour offers more protection than soft body armour, but it is much more cumbersome. Police officers and military personnel may wear this sort of protection when there is high risk of attack, but for everyday use they generally wear soft body armor, flexible protection that you wear like an ordinary shirt or jacket.

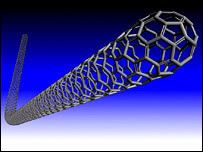

For hard armour, the field of investigation was the area of inorganic fullerenes; tubular or spherical nanocomposites of tungsten disulfide in particular. First proposed as a ballistic protection by the Israeli-based ApNano corporation, research into tungsten disulfide had proceeded independently for some time, despite considerable interest from a large number of national military and police forces. The Protectorate Research and Development Commission entering into an information-sharing agreement with the group in late 2006. A manufacturer of other high-strength armour-ceramic materials, such as boron carbide and silicon carbide, ApNano's research showed tungsten disulfide granting at least twice the protection level of equivalent mass boron carbide, between 4 and 5 times stronger than steel, and 6 times the strength of kevlar.

The second area of interest was the development of synthetic aciniform spidersilk. The use of synthetic spider silk to replace current materials in a host of applications has, until recently, been a step too far for materials science. In 2000, however, man-made spider silk moved a step nearer with the news that Canadian-based Nexia Biotechnologies Inc and the US Army Soldier Biological Chemical Command had collaborated to spin the world’s first man-made spider silk. Its commercial production has been something of a holy grail for materials scientists for many years, not least because it is known to be tougher, in terms of energy required to break, and less dense, than steel or Kevlar. As with the information sharing agreement with ApNano, a multi-billion dollar research grant provided by the Lyran Protectorate Research and Development Commission facilitated the joint-venture. Preliminary findings suggest that a strand of synthetic aciniform spider silk can be up to 20 times stronger than an equivalent strand of steel.

Importantly, it is also possible to combine tungsten disulfide nanotubes with other substances in order to expand the range of capabilities. For instance, mixing IF with highly elastic materials can lead to new compounds which are both flexible and shock-absorbing. These properties position tungsten-disulfide/synthetic aciniform spider silk materials as one of the best candidates for contemporary military-grade protective equipment and armour.

Manufacturing processes;

“Dauntless” is not a single grade of armour or homogenous material. Rather, it is an adaptable system designed to meet the diverse protection and mobility needs of combat soldiers. Capacity for adding additional protection is very much present within the system, allowing the individual end-user or subunit to determine the most combat effective configuration for any given circumstance.

In general terms, the armour is composed of two elements, the hard and soft components. The base level of the armour is the soft components, designed not to stop a round at any given point, but to disperse the impact over as broad an area as possible. The material used for this purpose is anciniform silk from spiders of the Nephila genus, specifically Nephila Maticulata, the Giant Wood Spider. It is worth noting, at this point, that anciniform silk is considerably stronger than that used for spinning webs, and is used primarily for securing prey once captured.

Farming spiders has been attempted, in the past, but with extremely limited success, and at very high labour cost. Spiders are predatory and unabashedly cannibalistic. Initial forays into attempts to generate spider silk through other means have been many and varied, with the first attempts (from Nexia biotechnologies) being by way of genetically modifying goats, in order to secrete the correct proteins in their milk, which would then be brought together in the appropriate fibrous form for weaving into ultra-high strength silk.

The method, while successful in principle, did have a number of flaws. Chief amongst them was the very large number of goats required to produce industrially feasible quantities of the genetically modified proteins. Specifically, it would take 200 goats to make a single vest in a day... an impractical solution for a state such as Lyras, where every single man, woman and child of a population greater than 5 billion would require body armour.

Subsequent attempts to gene-splice the required sequences into silkworms was, however, a resounding success, with the process moving beyond the ADF-3 and ADF-4 proteins that constitute the required spider silk, and into organic production of the silk itself.

Silkworms extruding spider silk, enlarged.

(Image)

At a stroke the vast majority of extant problems of farming industrial or commercial quantities of spider silk were solved, and the material became feasible. Rates of production for the substance continue to increase, as the Protectorate both seeks to armour its own populace, and concurrently attempts to generate inventory for distribution through export.

Once spun, the silk is woven into protective clothing in the same manner as clothing anywhere. The fibres mesh well, and fibrous internal friction is low while elasticity and tensile strength both remain very high, allowing for exceptionally good multi-shot resistance, particularly so when compared to other soft armours. The fibres, unusually, become proportionally stronger as they get thinner, and research and implementation quickly established what spiders established millions of years ago, that weaving 100 thin fibres into a silken strand is almost 60% stronger than an equivalent width single strand, while utilising (approximately) only 80% of the material mass. Also, critically, spider silk has a biphasic modulus – when initially subjected to force it is very stiff, like Kevlar, but just before the yield point it becomes very elastic, like Nylon. It also undergoes hysteresis, so if released from tension it comes back into shape. Upon the completion of the armour or garment, various coatings are applied in the conventional sense, such as anti-UV protective coatings and Xylane waterproofing.

Spider silk is also, when compared to alternative ballistic-grade fibres, extremely comfortable, being smooth, lightweight and breathable. When the properties are simultaneously taken into account, some of the potential of the substance becomes readily apparent.

The second element of the armour's protection are its 'hard' components, the sections designed to outright stop incoming projectiles. Where previously this required the existence and implementation of extremely bulky ceramic plates (or similar), “Dauntless” has implemented the first widescale application of inorganic fullerenes in the form of tungsten disulfide (WS2) within ballistic armours.

In contrast to organic (carbon-based) Fullerenes, WS2 is easier and much less expensive to produce, is chemically stable and is dramatically less reactive and less flammable. Organic fullerenes are also considered to be highly toxic, whereas WS2, like most other inorganic fullerenes, is not. As WS2 forms, it does so in layers, much like graphite, which is - along with diamond - one of two common forms carbon takes in nature. In WS2, molecules are bonded in trigonal prismatic layers, similar to MoS2. These form flat layers that are stacked on top of one another like sheets of paper.

When making nanotubes, the process, in essence, takes individual layers and folds them over so they join at either edge to form cylinders. Illustration is provided below.

(Image)

In an interview recorded in late 2005, Dr. Menachem Genut, ApNano CEO, explained that the company was moving into semi-industrial manufacturing within the next six months producing between 100-200 kilograms of the material per day, gradually moving to full-scale industrial production by 2007, which lead to the production of several tons each day. Although it was difficult to determine the exact price of the "nano-armor" when in full industrial production, given the cost of the original materials and the relatively low production costs, Dr. Genut stated (in 2005) that a kilogram of the new material will cost considerably less than a similar amount of the carbon-based Fullerenes. As at the time of interview, the company was optimistic that with some external financial backing it will be possible to have the first product ready in less then three years.

The Lyran Protectorate was more than happy to provide such backing, which it did to the tune of NS$18 billion. That investment has reaped the requisite rewards, with multiple manufacturing complexes now devoted to production of the materials required for the production of “Dauntless”.

Signature reduction

“Dauntless” provides the highest level of signature reduction of any body armour released onto the market to date, borrowing as it does from the innovations introduced in the still-new Lyran Disruptive Pattern Camouflage Uniform (LDPCUs), which was itself designed with the ongoing development and anticipated completion of “Dauntless” in mind.

To that end, infra-red suppression, carried out in parallel to that provided by the LDPCUs, was determined to be of paramount importance. As hinted in an interview with then-Major McReedy, who was the assistant project manager and military technical advisor to the LDPCU program, the Protectorate Research and Development Commission was examining means of transferring the IR-suppressive techniques over to other applications.

The final decision was, in retrospect, painfully simple. All body armour, after manufacture, is provided with a fabric covering layer, coloured in a pattern appropriate to the intended area of use. For “Dauntless”, the Research and Development Commission took this idea further, providing for the fitting of one of any number of after-manufacture camouflage covers, to be applied over the armour. These fabric covers utilise the same multi-spectral camouflage adaptations pioneered for use on the LDPCUs, and provides for dramatically reduced visibility when seen through 3rd or 4th generation night vision or thermal imaging equipment.

By means of illustration, the figure on the right is wearing the new IR-suppressed LDPCU uniform the other one is wearing the old-style ACU. While no photographs of personnel in “Dauntless” were available, the technology applied is identical. This photo was taken from a distance of 12 metres.

(Image)

LDPCU coverings to the “Dauntless” body armour are NOT to be starched, as starch can cause discolouration, and interferes with the IR-suppression properties. This will enhance the IR signature, making the uniform brighter when viewed with night vision goggles. Further, strong detergents may discolour the uniform, and again may react to neutralise the IR-suppression.

LDPCU fabric coverings are also not to be ironed, as the extensive heat application may damage the fibrous chemical treatment. If washing is required (as it will be, at some point), cold machine wash, and drip dry where possible.

Modularity

The Lyran Protectorate has, for some time, been issuing chest webbing as standard, featuring (as many other nations' chest webbing also features) velcro and plastic straps and clips so as to secure equipment to the person. The 'Dauntless' armour takes this a step further, with the armour itself able to accept the various equipment pouches and containers required by a combatant, with the armour insert pouches themselves able to double as containers, if not used to carry the additional armour.

Most internationally standard attachments should have no issue fitting to 'Dauntless', and if there are issues, custom fits can be arranged free of charge.

Protective qualities

Protective qualities of “Dauntless” are divided, again, into hard and soft armour for individual analysis, and a synopsis will be provided at the conclusion.

In mid-2005, research into WS2 was conducted at the University of Nottingham, England. A sample of the material was subjected to severe shocks, from a steel projectile moving at speeds of up to 1.5 km/second. The tungsten disulfide withstood the impacts of up to 250 tons per square centimeter. This is approximately equivalent to dropping four diesel locomotives onto an area the size of ones fingernail. During the test the material proved to be so strong that after the impact the samples remained essentially unchanged, when compared to the original material. Additionally, a recent study by Prof. J. M. Martin from Ecole Centrale de Lyon in France tested the new material under isostatic pressure and found it to be stable up to at least 350 tons/cm2

Tungsten disulfide is relatively heavy, however and for that reason the plates utilising WS2 are substantially thinner than their -carbide equivalents. Further, due to the purpose of the research being to lower the body armour weight, not increase it, the plates were made thinner to the point of being lighter than their predecessors. Given the greatly superior ballistic protection offered by WS2, however, the plates, despite being considerably thinner and lighter, offer dramatically improved protective performance. This is achieved by using WS2 backed by the lighter boron carbide. The impact resistance of the WS2 is utilised to blunten the impact of the projectile, and 'decap' inbound rounds, while the backing absorbs the remainder of the kinetic energy, and continues to distribute the energy while keeping weight low.

For the purposes of reference, the table below details the official body armour levels, as defined by the U.S. National Institute of Justice, Standard 0101.04.

Armor Level

Type I

(.22 LR; .380 ACP)

This armor protects against 22 calibre Long Rifle Lead Round Nose (LR LRN) bullets, with nominal masses of 2.6 g (40 gr) at a reference velocity of 329 m/s (1080 ft/s ± 30 ft/s) and .380 ACP Full Metal Jacketed Round Nose (FMJ RN) bullets, with nominal masses of 6.2 g (95 gr) at a reference velocity of 322 m/s (1055 ft/s ± 30 ft/s)

Type IIA

(9 mm; .40 S&W)

This armor protects against 9 mm Full Metal Jacketed Round Nose (FMJ RN) bullets, with nominal masses of 8.0 g (124 gr) at a reference velocity of 341 m/s (1120 ft/s ± 30 ft/s) and .40 S&W calibre Full Metal Jacketed (FMJ) bullets, with nominal masses of 11.7 g (180 gr) at a reference velocity of 322 m/s (1055 ft/s ± 30 ft/s). It also provides protection against the threats mentioned in [Type I].

Type II

(9 mm; .357 Magnum)

This armor protects against 9 mm Full Metal Jacketed Round Nose (FMJ RN) bullets, with nominal masses of 8.0 g (124 gr) at a reference velocity of 367 m/s (1205 ft/s ± 30 ft/s) and 357 Magnum Jacketed Soft Point (JSP) bullets, with nominal masses of 10.2 g (158 gr) at a reference velocity of 436 m/s (1430 ft/s ± 30 ft/s). It also provides protection against the threats mentioned in [Types I and IIA].

Type IIIA

(High Velocity 9 mm; .44 Magnum)

This armor protects against 9 mm Full Metal Jacketed Round Nose (FMJ RN) bullets, with nominal masses of 8.0 g (124 gr) at a reference velocity of 436 m/s (1430 ft/s ± 30 ft/s) and .44 Magnum Semi Jacketed Hollow Point (SJHP) bullets, with nominal masses of 15.6 g (240 gr) at a reference velocity of 436 m/s (1430 ft/s ± 30 ft/s). It also provides protection against most handgun threats, as well as the threats mentioned in [Types I, IIA, and II].

Type III

(Rifles)

This armor protects against 7.62 mm Full Metal Jacketed (FMJ) bullets (U.S. Military designation M80), with nominal masses of 9.6 g (148 gr) at a reference velocity of 847 m/s (2780 ft/s ± 30 ft/s) or less. It also provides protection against the threats mentioned in [Types I, IIA, II, and IIIA].

Type IV

(Armour Piercing Rifle)

This armor protects against .30 calibre armour piercing (AP) bullets (U.S. Military designation M2 AP), with nominal masses of 10.8 g (166 gr) at a reference velocity of 878 m/s (2880 ft/s ± 30 ft/s). It also provides at least single hit protection against the threats mentioned in [Types I, IIA, II, IIIA, and III].

There are, at present, three general classes of protection offered. The first is the spider-silk only torso and leggings, known as 'Arachne' for ease of differentiation, and rated to level IIIA. This armour is designed specifically to be very comfortably and uninhibiting in movement or weight, and fits easily under clothing, or under the second type of armour. 'Arachne' is breathable, lightweight, and available for purchase by any supernational, national, paranational or private entity. 'Arachne' weighs in at 2.3kg, although is less than a third the bulk of an equivalent weight of kevlar.

The second and third classes of protection under the 'Dauntless' armour share the primary component, that being the ballistic vest itself. Made from a soft armour base composed of the same material as the 'Arachne', the 'Dauntless' system itself is thicker, with more layers of the same substance, and features a number of zip-closed, velcro-covered pockets into which are inserted the WS2/boron-carbide composite plates. The degree of protection delivered is modular... the more protection required, the more plates can be inserted. With the addition of the composite plates, the armour is rated at level IV+, the plus being indicative of the fact that the official chart only goes up that far. The system has been tested as providing at least single hit protection against 12.7 x 99mm fire at ranges outside 150m. Expect a whopping great bruise, however, and to be knocked clean off your feet and possibly backwards a couple of metres. Use of a helmet is advised to avoid secondary damage.

The 'Dauntless' vest weighs 6.1kg on its own, and, when all inserts are added, weighs 15.5kg.

Pushing up to the third level is achieved by means off combining both layers, with the 'Arachne' worn underneath the 'Dauntless' vest. The level of protection offered by this multi-layered approach is, as would be expected, fairly high. Total weight would thereby reach 17.7kg, and is not recommended for long distance dismounted operations.

Available in conjunction are upper arm and upper leg protection, with the upper arms rated at III, and legs rated at IV.

Export

'Dauntless' and its 'Arachne' sub-set together represent a significant move forward in contemporary armour technology. It provides dismounted infantry with flexible high-grade protection for the modern battlespace. It is, however, not cheap, as reflects the nature of the product. Also, it is proprietary technology, and Lyran Arms DOES NOT offer DPRs to non-allied states.

Examples of the armour are available at the following cost;

'Arachne' vest; NS$4,900

'Dauntless' vest; NS$6,200

WS2/Boron carbide inserts; NS$7,400

'Dauntless' and inserts; NS$13,200

'Arachne' + 'Dauntless' + inserts; NS$18,000

Special considerations are available, as per Executive Command decision, to TPF, Asgarnieu, the Federal Republic of Hamilay, Verenberg, Errikland, Bomble, Varessa, Mokastana, the Revolutionary Commonwealth of Wagdog, Lamoni, Dictatorial Republic of Sumer, and select other nations.

Purchases are made through Lyran Arms.

UPDATE, 24 AUG 2008

In accordance with Executive Command sanctioned analysis and directives, 'Dauntless' Ballistic Armour, and its derivatives, is NOT AVAILABLE to states not in strategic partnership with the Lyran Protectorate, in one form or another. Lyran Arms, as a subsidiary unit to the Governmental Trade Department, is contactable for questions, and reserves the right to refer to Executive Command in the case of dispute. Pre-existing purchases are recognised, and customer support will continue, despite export restrictions.

References

Online sources only listed... hard copy source list available on request.

Super-strong body armour; nanotubes and their production

http://news.bbc.co.uk/2/hi/science/nature/7038686.stm

Protecting the soldiers of tomorrow (published February 15, 2006)

http://www.isracast.com/article.aspx?id=28

Synthetic spider silk

http://www.azom.com/details.asp?ArticleID=1543

National Geographic, 2005; Transgenic goats and Biosteel

http://news.nationalgeographic.com/news ... der_2.html

Wikipedia – Body Armour

http://en.wikipedia.org/wiki/Body_armor

Wikipedia - Tungsten Disulfide (How could one not?)

http://en.wikipedia.org/wiki/Tungsten_disulfide

Wikipedia – Spider silk (Again, how could one not?)

http://en.wikipedia.org/wiki/Spider_silk

Advances in ballistic armour research:

http://illumin.usc.edu/article.php?articleID=156&page=4

MOAA, 2003 on connections between US Army Materiel Command and Nexia

http://www.moaa.org/magazine/January...erwarriors.asp

Nephila Maculata – Webs of Steel; the Giant Wood Spider

http://www.naturia.per.sg/buloh/inverts/nephila.htm

Synthesis of spidersilk from transgenic goats – a periodical;

http://www.gene.ch/genet/2004/Jan/msg00026.html

Basic Ballistics, Anthony Williams © 2008.

http://www.quarry.nildram.co.uk/ballistics.htm

Digital Dutch Unit Converter

http://www.digitaldutch.com/unitconverter/energy.htm

Yanitarian BDUs

http://z4.invisionfree.invalid.com/NSDraftroom/ ... topic=1531

Finding Inspiration in Spider Silk Fibres

http://www.tms.org/pubs/journals/JOM...ices-0502.html

Imperializt Russia wrote:Support biblical marriage! One SoH and as many wives and sex slaves as he can afford!

![]() by Aqizithiuda » Wed Apr 03, 2013 10:34 pm

by Aqizithiuda » Wed Apr 03, 2013 10:34 pm

Nationstatelandsville wrote:I liked the prostitute - never quote me on that.

Puzikas wrote:This is beyond condom on toes. This is full on Bra-on-balls.

Puzikas wrote:Im not cheep-You can quote me on that.

Hellraiser-Army wrote:and clearly I am surrounded by idiots who never looked at a blueprint before...

![]() by Kaukolastan » Wed Apr 03, 2013 10:41 pm

by Kaukolastan » Wed Apr 03, 2013 10:41 pm

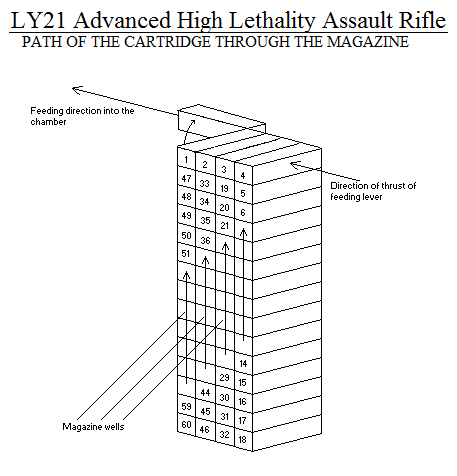

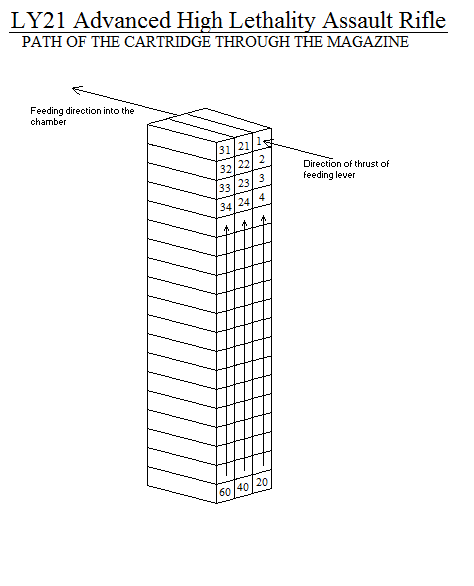

Aqizithiuda wrote:I wqs just thinking, Lyras, that I have some vague memory of someone on NSD saying that you'd figured out how the G11 LMG's mag worked and had incorporated a modified version into the LY21. Am I remembering things right?

N. Enartio, Justifying his Nuclear Powered, "EMP Laser" Shooting, Nazi Flying Saucer wrote:It isn't bad, i used science.

![]() by Lyras » Wed Apr 03, 2013 10:44 pm

by Lyras » Wed Apr 03, 2013 10:44 pm

Mokastana: Then Lyras happened.

Allanea: Wanting to avoid fighting Lyras' fuck-huge military is also a reasonable IC consideration

TPF: Who is stupid enough to attack a Lyran convoy?

Sumer: Honestly, I'd rather face Doom's military with Doom having a 3-1 advantage over me, than take a 1-1 fight with a well-supplied Lyran tank unit.

Kinsgard: RL Lyras is like a real life video game character.

Ieperithem: Eighty four. Eighty four percent of their terrifyingly massive GDP goes directly into their military. And they actually know how to manage it. It's safe to say there isn't a single nation that could feasibly stand against them if they wanted it to die.

Yikes. Just... Yikes.

![]() by Aqizithiuda » Wed Apr 03, 2013 10:49 pm

by Aqizithiuda » Wed Apr 03, 2013 10:49 pm

Lyras wrote:That was, indeed, how the LMG11 mag worked. I just super-simplified the pathing of the magazines, for the triple-single stack 60rnd magazine. Uses a bolt-catch at the bottom of each separate well within the magazine to rotate the primary bolt face, which then catches the next round, from the second well, and thence the third. That's the short version, anyway.

And Spirit of Hope, thank you. 'tis appreciated.

Nationstatelandsville wrote:I liked the prostitute - never quote me on that.

Puzikas wrote:This is beyond condom on toes. This is full on Bra-on-balls.

Puzikas wrote:Im not cheep-You can quote me on that.

Hellraiser-Army wrote:and clearly I am surrounded by idiots who never looked at a blueprint before...

Advertisement

Return to Factbooks and National Information

Advertisement